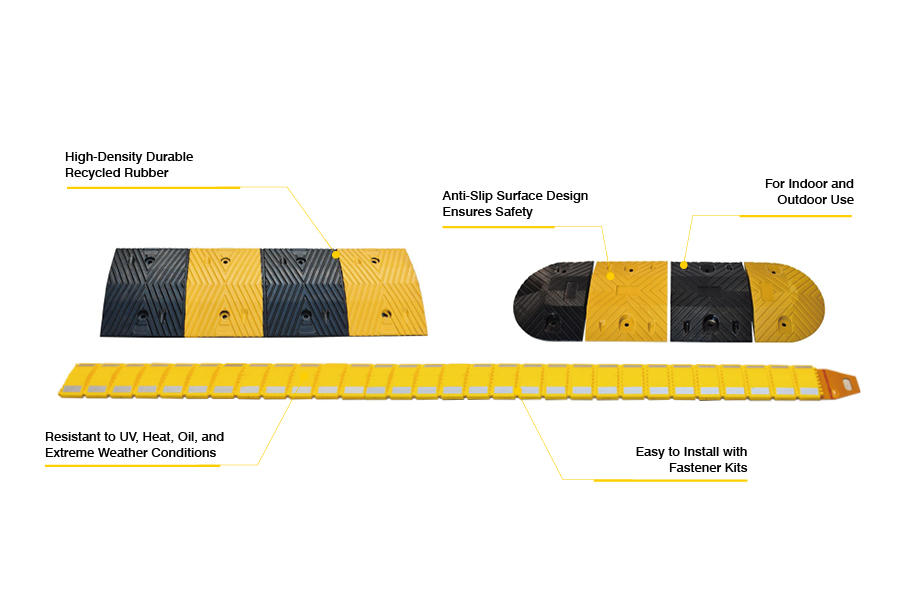

Optsigns speed bump is crafted from high-density recycled rubber, ensuring exceptional durability and resistance to UV rays, heat, oil, and extreme weather conditions. This makes speed bump an ideal choice for maintaining safety and controlling traffic speed in various environments. Whether you need to slow down vehicles in parking lots, school zones, commercial areas, residential neighborhoods, or industrial facilities, our speed bump provides an effective solution. Its robust design not only enhances safety but also contributes to environmental sustainability through the use of recycled materials.

Optsigns speed bump is crafted from high-density recycled rubber, ensuring exceptional durability and resistance to UV rays, heat, oil, and extreme weather conditions. This makes speed bump an ideal choice for maintaining safety and controlling traffic speed in various environments. Whether you need to slow down vehicles in parking lots, school zones, commercial areas, residential neighborhoods, or industrial facilities, our speed bump provides an effective solution. Its robust design not only enhances safety but also contributes to environmental sustainability through the use of recycled materials.

*We respect your confidentiality and all information are protected.

| Size | 1000*400*50mm (Middle, 15kgs), 250*400*50mm (End, 3.25kgs) |

|---|---|

| Material | Recycled Rubber |

| Colour | Yellow and Black |

| Surface | Anti-Slip Design |

| Load Capacity | 15t |

| Customize | Custom Size and Weight |

Using Optsigns road hump is straightforward. Begin by selecting a suitable location where traffic speed needs to be reduced, such as a parking lot or school zone. Ensure the area is clear of obstacles before installation. Position the road hump parallel to the roadway and secure it firmly in place, following the manufacturer’s guidelines. The road hump should be visible to drivers, so consider adding signage if necessary. Once installed, the road hump will effectively slow down traffic, promoting safety for pedestrians and drivers alike.

Flashing barricade lights are designed to enhance safety by providing clear visibility in various environments. They are commonly used at construction sites, roadworks, and public events to alert drivers and pedestrians of potential hazards and ensure effective traffic management.

Flashing barricade lights are designed for low power consumption and typically operate on batteries. This ensures long-lasting illumination without frequent replacements. Be sure to check the power source before each use for optimal performance.

Yes, flashing barricade lights are built to withstand various weather conditions. Their durable, weather-resistant design ensures reliable performance in rain, snow, and extreme temperatures, making them suitable for both indoor and outdoor applications.

Flashing barricade lights utilize advanced LED technology, providing bright illumination that is easily visible from a distance. Their high visibility ensures flashing barricade lights effectively alert drivers and pedestrians, enhancing safety in high-traffic areas.

Absolutely! Flashing barricade lights are specifically designed for low-light conditions and are highly effective at night. Their bright LED illumination ensures that they remain visible and effective in alerting drivers and pedestrians to potential hazards.