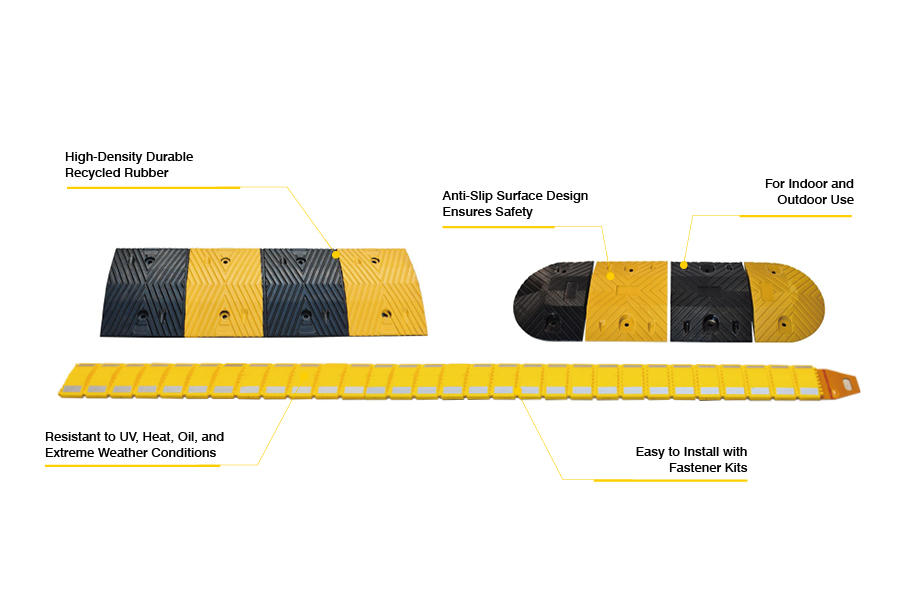

Optsigns speed bump is crafted from high-density recycled rubber, ensuring exceptional durability and resistance to UV rays, heat, oil, and extreme weather conditions. This makes speed bump an ideal choice for maintaining safety and controlling traffic speed in various environments. Whether you need to slow down vehicles in parking lots, school zones, commercial areas, residential neighborhoods, or industrial facilities, our speed bump provides an effective solution. Its robust design not only enhances safety but also contributes to environmental sustainability through the use of recycled materials.

Optsigns speed bump is crafted from high-density recycled rubber, ensuring exceptional durability and resistance to UV rays, heat, oil, and extreme weather conditions. This makes speed bump an ideal choice for maintaining safety and controlling traffic speed in various environments. Whether you need to slow down vehicles in parking lots, school zones, commercial areas, residential neighborhoods, or industrial facilities, our speed bump provides an effective solution. Its robust design not only enhances safety but also contributes to environmental sustainability through the use of recycled materials.

*We respect your confidentiality and all information are protected.

| Size | 1000*380*50mm (Middle, 18kgs), 190*380*50mm (End, 2kgs) |

|---|---|

| Material | Recycled Rubber |

| Colour | Yellow and Black |

| Surface | Anti-Slip Design |

| Load Capacity | 15t |

| Customize | Custom Size and Weight |

Using Optsigns road hump is straightforward. Begin by selecting a suitable location where traffic speed needs to be reduced, such as a parking lot or school zone. Ensure the area is clear of obstacles before installation. Position the road hump parallel to the roadway and secure it firmly in place, following the manufacturer’s guidelines. The road hump should be visible to drivers, so consider adding signage if necessary. Once installed, the road hump will effectively slow down traffic, promoting safety for pedestrians and drivers alike.

A traffic hump is similar to a speed hump; traffic hump is a raised section of the roadway designed to slow down traffic. Traffic humps are generally less severe than speed bumps and are used in various traffic calming measures.

Optsigns Speed Bump is made from high-density recycled rubber, which provides durability and resistance to UV rays, heat, oil, and extreme weather conditions, making it suitable for various environments.

You can install Optsigns speed bumps and humps in multiple locations, including parking lots, school zones, commercial areas, residential neighborhoods, and industrial facilities, to help reduce traffic speed and enhance safety.

Rubber speed bumps are highly effective at slowing down vehicles, helping to maintain a safe environment for pedestrians and drivers. Their design encourages drivers to reduce speed, particularly in high-traffic areas.

Yes, Optsigns rubber speed hump is designed for outdoor use and is resistant to various weather conditions, including rain, snow, and extreme heat, ensuring long-lasting performance in any environment.

Absolutely! Road speed bumps work well alongside other traffic control devices such as signage, traffic cones, and road barriers to create a comprehensive safety strategy for managing vehicle speed and enhancing overall safety.

In slang, “speed bump” can refer to a minor obstacle or inconvenience in life, akin to the physical speed bumps that slow down vehicles. Speed bump can also describe a small hurdle that needs to be overcome.

Yes,speed bumps for driveways are effective in reducing vehicle speed and improving safety in areas with high pedestrian traffic. Speed bumps for driveways encourage drivers to slow down, which can decrease the likelihood of accidents and enhance safety for pedestrians and cyclists.