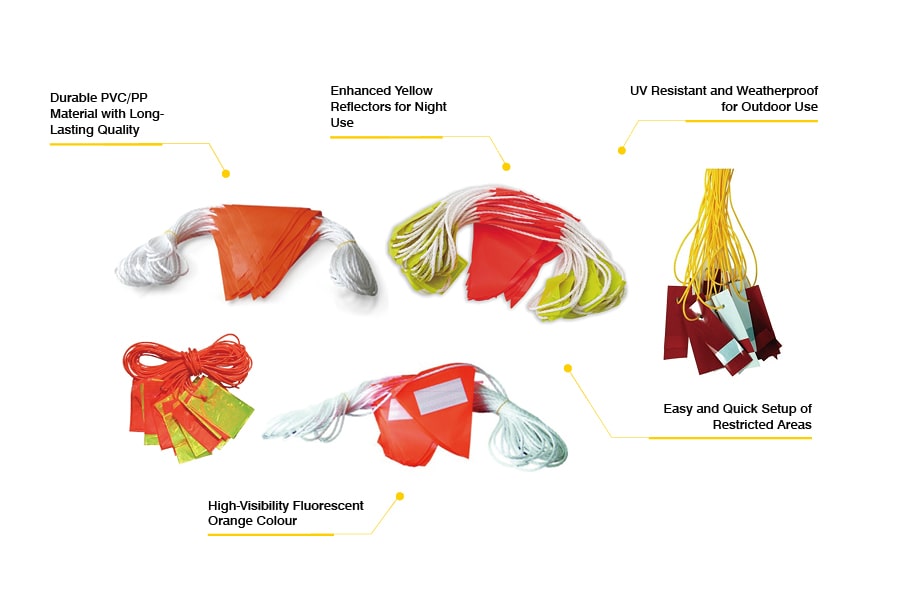

OPTsigns Night Line features HIP/Class 1 reflective film for superior visibility, ensuring safety in all conditions. Constructed from durable PVC/PP materials, it offers long-lasting quality and is designed for harsh environments. The fluoro PVC night line is both UV-resistant and weatherproof, making it ideal for outdoor use. This night line rope with reflective tags is quick and easy to set up, providing efficient crowd control and traffic management at low cost.

Widely used in roadworks, parking lots, construction sites, and hazardous areas, the reflective warning night line enhances safety by marking restricted zones. Available as a night line in roll, it simplifies deployment for various applications. For higher visibility, options like the orange warning night line and red warning night line can be used to meet specific safety requirements. The traffic safety night line rope and reflective night line are versatile, making them perfect for creating secure boundaries in the mining and demolition industries.

*We respect your confidentiality and all information are protected.

| Sheet Size | 50*150mm |

|---|---|

| Length | 25m |

| Colour | Red & White |

| Material | PP Plastic Sheets with a PVC Rope |

| Reflective Film | None, Commercial Grade, Class 1, Customizable |

| Customize | Logo and Marking |

To use a Bunting Line, first identify the area where you want to create a visual boundary or warning. Unroll the bunting line and secure the ends to stable posts, cones, or hooks, ensuring it’s taut but not overly stretched. Position the fluoro PVC bunting line at a height and angle visible to oncoming pedestrians or vehicles. For longer distances, use additional supports to prevent sagging.

Flashing barricade lights are designed to enhance safety by providing clear visibility in various environments. They are commonly used at construction sites, roadworks, and public events to alert drivers and pedestrians of potential hazards and ensure effective traffic management.

Flashing barricade lights are designed for low power consumption and typically operate on batteries. This ensures long-lasting illumination without frequent replacements. Be sure to check the power source before each use for optimal performance.

Yes, flashing barricade lights are built to withstand various weather conditions. Their durable, weather-resistant design ensures reliable performance in rain, snow, and extreme temperatures, making them suitable for both indoor and outdoor applications.

Flashing barricade lights utilize advanced LED technology, providing bright illumination that is easily visible from a distance. Their high visibility ensures flashing barricade lights effectively alert drivers and pedestrians, enhancing safety in high-traffic areas.

Absolutely! Flashing barricade lights are specifically designed for low-light conditions and are highly effective at night. Their bright LED illumination ensures that they remain visible and effective in alerting drivers and pedestrians to potential hazards.