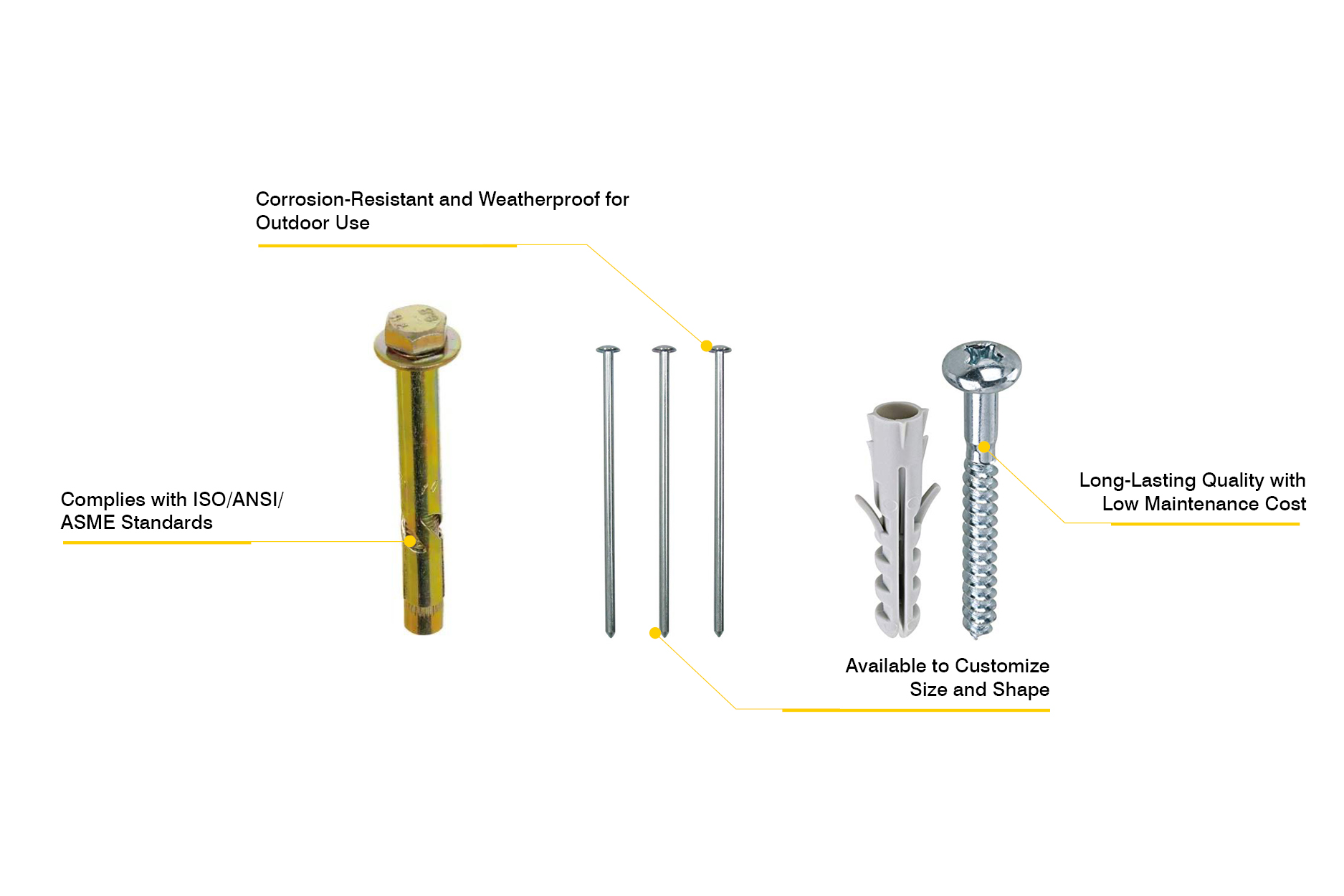

Manufactured with advanced electro-galvanized coating technology, OPTsigns Long Spikes offer outstanding corrosion resistance and weatherproof durability, ensuring reliable performance in outdoor environments. Built to withstand harsh conditions, these long metal spikes provide long-lasting quality with minimal maintenance costs, making them ideal for securing wheel stops, brackets, traffic signs, road delineators, and other essential road safety products. Their design complies with ISO, ANSI, and ASME standards, underscoring a commitment to high-quality, standardized road safety solutions.

Manufactured with advanced electro-galvanized coating technology, OPTsigns Long Spikes offer outstanding corrosion resistance and weatherproof durability, ensuring reliable performance in outdoor environments. Built to withstand harsh conditions, these long metal spikes provide long-lasting quality with minimal maintenance costs, making them ideal for securing wheel stops, brackets, traffic signs, road delineators, and other essential road safety products. Their design complies with ISO, ANSI, and ASME standards, underscoring a commitment to high-quality, standardized road safety solutions.

Available in customizable sizes and shapes, OPTsigns long spikes for rubber wheel stops and speed humps steel spikes offer versatility for various applications. The robust build of these steel spikes for rubber speed humps delivers enhanced stability and safety across different settings, effectively securing installations and minimizing movement or damage from heavy use.

*We respect your confidentiality and all information are protected.

| Size | ��12*120mm, ��12*160mm, ��12*300mm, Customizable |

|---|---|

| Material | Galvanized Steel, Stainless Steel |

| Packing | Standard, Plastic Bag, Customizable |

| Customize | Size and Shape |

To use dynabolts, first select the appropriate size based on your project’s needs. Refer to the dynabolt installation guide for detailed instructions. Ensure the installation surface, like concrete, is clean and free of debris. Place the galvanized dynabolts through the fixture and into the pre-drilled hole, then tighten using a suitable tool.

Dynabolts function by expanding within a pre-drilled hole when tightened, creating a secure anchor. This expansion mechanism allows them to hold substantial loads. The stainless steel dynabolts are particularly effective in resisting corrosion, ensuring a long-lasting hold in various environments.

To install a dynabolt, first drill a hole into the concrete of the appropriate size. Insert the dynabolt into the hole, ensuring it is aligned with the fixture. Use a wrench to tighten the nut, which will cause the dynabolt to expand and grip the surrounding material securely. Follow the dynabolt installation guide for specific instructions based on the type used.

To remove dynabolts from concrete, first, unscrew the nut and washer. Then, use a hammer to gently tap the dynabolt, loosening it from the concrete. If it resists, you may need to drill further into the hole or use a wrench to rotate the galvanized dynbolt counterclockwise until it releases.

The weight a dynabolt can hold varies based on its size and the material it is anchored into. Generally, standard galvanized dynabolts can support significant loads when properly installed.