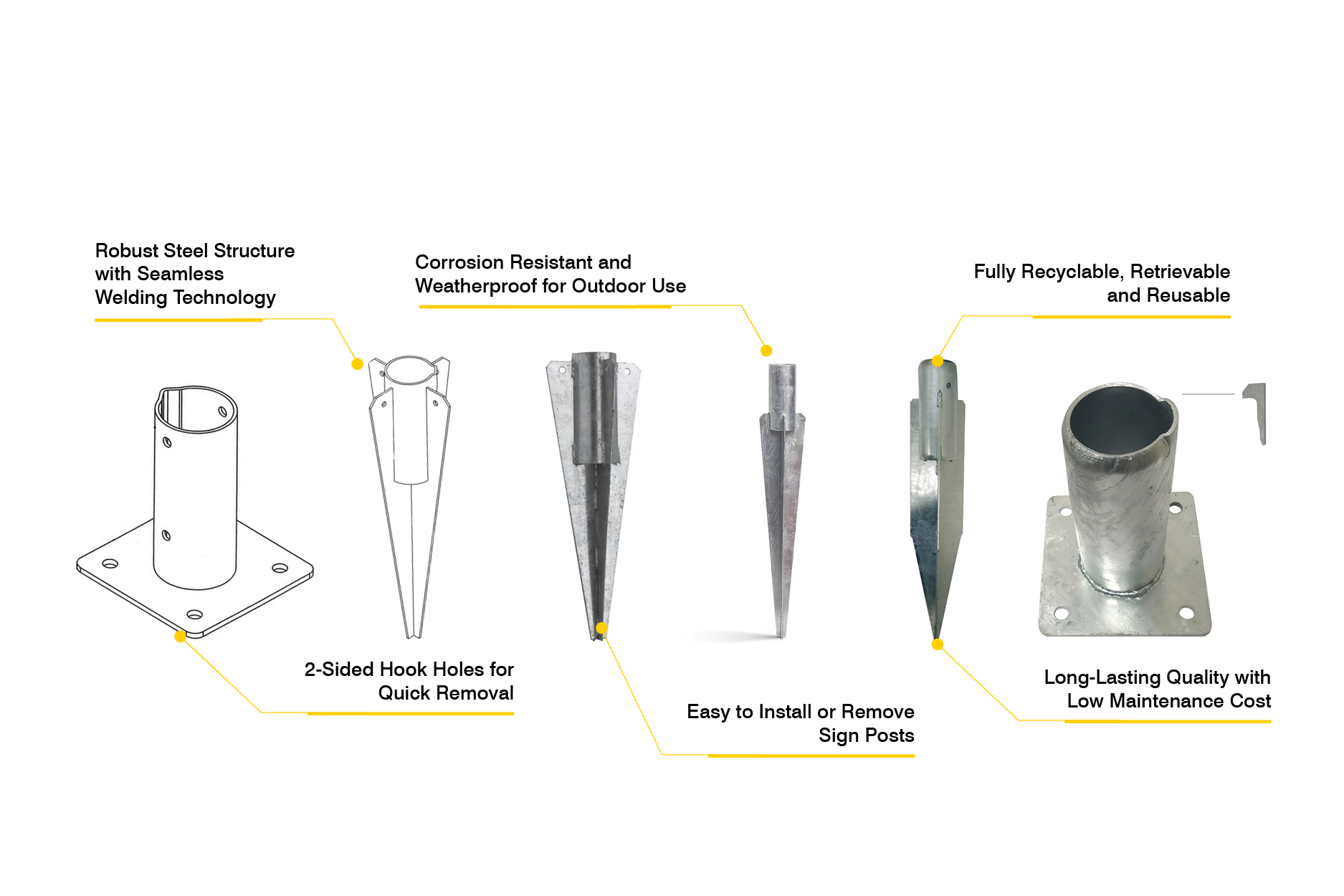

OPTsigns galvanized ground spikes offer a robust steel structure enhanced by seamless welding technology, ensuring a durable and corrosion-resistant solution for outdoor use. Designed for both stability and efficiency, these metal ground spikes can be effortlessly inserted into the ground, eliminating the need for digging holes or pouring concrete. Their easy installation process allows for quick setup and removal of sign posts and fences, while the 2-sided hook holes enable rapid adjustments. Fully recyclable and retrievable, these post anchor ground spikes not only provide long-lasting quality but also keep maintenance costs low.

OPTsigns galvanized ground spikes offer a robust steel structure enhanced by seamless welding technology, ensuring a durable and corrosion-resistant solution for outdoor use. Designed for both stability and efficiency, these metal ground spikes can be effortlessly inserted into the ground, eliminating the need for digging holes or pouring concrete. Their easy installation process allows for quick setup and removal of sign posts and fences, while the 2-sided hook holes enable rapid adjustments. Fully recyclable and retrievable, these post anchor ground spikes not only provide long-lasting quality but also keep maintenance costs low.

The post ground anchor design ensures maximum support, making these ground spikes an ideal choice for various applications. The fencing spikes for fence posts are crafted to withstand the elements, ensuring that installations remain secure and stable over time. Whether you’re using them as sign ground spikes or fence post spikes, OPTsigns metal spikes for ground guarantee a solution that is not only effective but also environmentally friendly.

*We respect your confidentiality and all information are protected.

| Height | 450mm, 600mm |

|---|---|

| Weight | 2.54kgs, 3.26kgs |

| Nominal Bore | 50mm Dia. |

| Thickness | 3mm |

| Material | Hot Galvanized Steel |

| Customize | Logo, Marking and Shape |

To use dynabolts, first select the appropriate size based on your project’s needs. Refer to the dynabolt installation guide for detailed instructions. Ensure the installation surface, like concrete, is clean and free of debris. Place the galvanized dynabolts through the fixture and into the pre-drilled hole, then tighten using a suitable tool.

Dynabolts function by expanding within a pre-drilled hole when tightened, creating a secure anchor. This expansion mechanism allows them to hold substantial loads. The stainless steel dynabolts are particularly effective in resisting corrosion, ensuring a long-lasting hold in various environments.

To install a dynabolt, first drill a hole into the concrete of the appropriate size. Insert the dynabolt into the hole, ensuring it is aligned with the fixture. Use a wrench to tighten the nut, which will cause the dynabolt to expand and grip the surrounding material securely. Follow the dynabolt installation guide for specific instructions based on the type used.

To remove dynabolts from concrete, first, unscrew the nut and washer. Then, use a hammer to gently tap the dynabolt, loosening it from the concrete. If it resists, you may need to drill further into the hole or use a wrench to rotate the galvanized dynbolt counterclockwise until it releases.

The weight a dynabolt can hold varies based on its size and the material it is anchored into. Generally, standard galvanized dynabolts can support significant loads when properly installed.