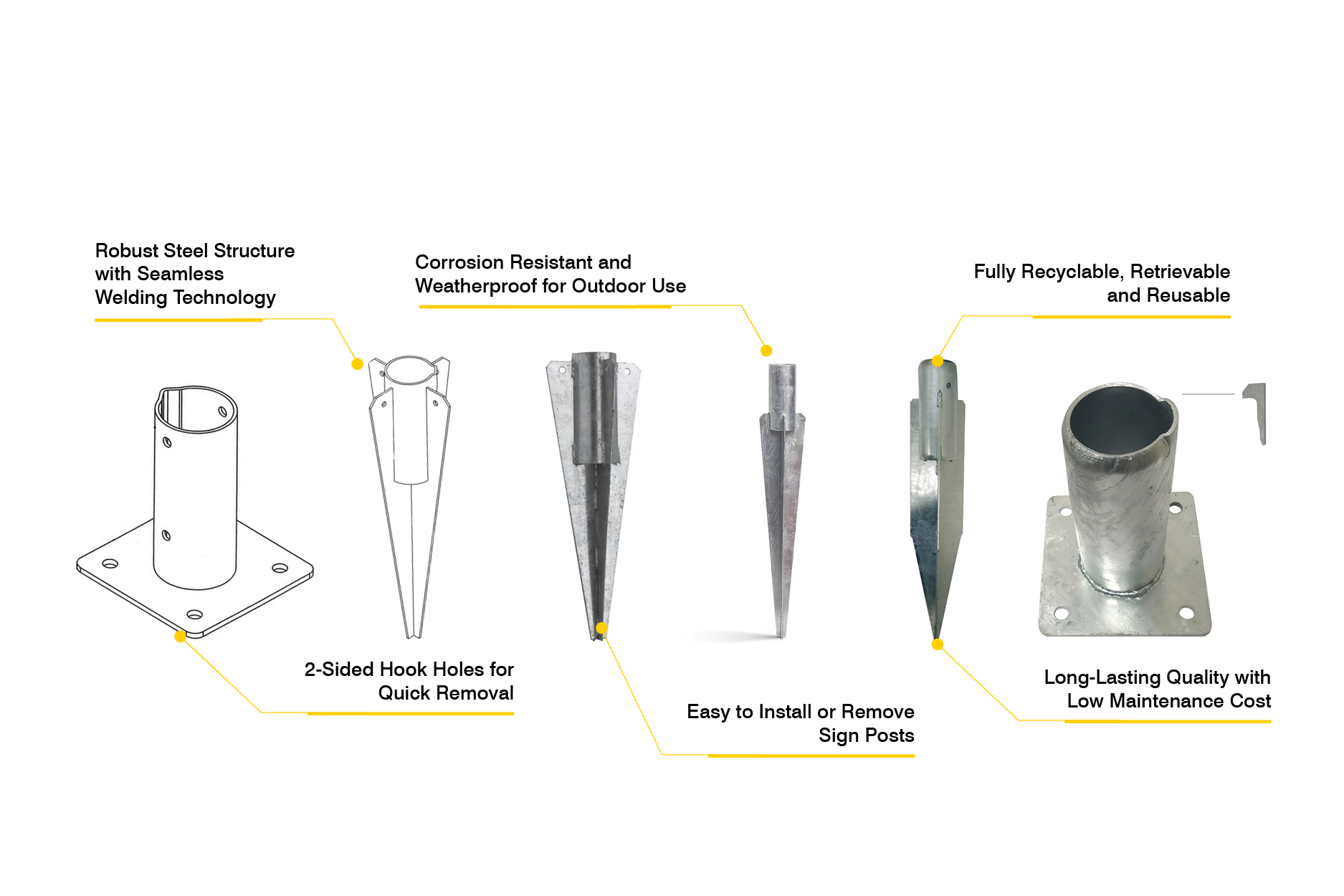

The OPTsigns ground spikes feature a robust steel structure enhanced with seamless welding technology, ensuring exceptional durability and stability. These galvanized ground spikes are corrosion-resistant and weatherproof, making them ideal for outdoor use. Fully recyclable and retrievable, our post anchor ground spikes provide a sustainable solution while maintaining long-lasting quality with low maintenance costs. Installation is a breeze, allowing for easy setup or removal of sign posts. With 2-sided hook holes designed for quick removal, these metal ground spikes streamline the process of adjusting or relocating your installations.

The OPTsigns ground spikes feature a robust steel structure enhanced with seamless welding technology, ensuring exceptional durability and stability. These galvanized ground spikes are corrosion-resistant and weatherproof, making them ideal for outdoor use. Fully recyclable and retrievable, our post anchor ground spikes provide a sustainable solution while maintaining long-lasting quality with low maintenance costs. Installation is a breeze, allowing for easy setup or removal of sign posts. With 2-sided hook holes designed for quick removal, these metal ground spikes streamline the process of adjusting or relocating your installations.

Whether you need a reliable fence post anchor or a durable solution for securing signs, our post spikes deliver outstanding performance. The versatility of these ground anchors for posts is evident in their compatibility with various applications, including fencing and signage. With options like heavy-duty ground spikes and fence post ground anchors, you can trust that your installations will remain secure and stable in any environment. Explore our ground anchor spikes to discover an effective anchoring solution that meets your needs while ensuring quality and longevity.

*We respect your confidentiality and all information are protected.

| Height | 450mm, 600mm |

|---|---|

| Weight | 2kgs, 2.7kgs |

| Nominal Bore | 60mm Dia. |

| Thickness | 3mm |

| Material | Hot Galvanized Steel |

| Customize | Logo, Marking and Shape |

| Option | Wedges |

Post spikes, especially those high-quality fence anchors made from hot galvanized steel, can last for many years for excellent durability and longevity, often exceeding a decade, depending on soil conditions and exposure to moisture

Yes, post spikes are a practical solution for securing posts without the need for digging. They provide excellent stability, especially when using heavy-duty ground spikes. These spikes are efficient for various applications, such as fences, wood posts and sign posts, making them a reliable choice.

To drive a fence post spike into the ground, first, mark the location where you want to install it. Use a sledgehammer or mallet to gently tap the spike into the ground until it is firmly anchored. Ensure the spike is vertical for optimal stability when using ground anchor spikes.

No, post spikes do not require concrete for installation. They are designed to be driven directly into the ground, providing a secure hold without the hassle of mixing and pouring concrete. This makes them convenient and time-efficient.

Yes, fence post spikes can be used for securing a pergola. They provide a sturdy base for the vertical posts of the structure, especially when using ground anchored spikes for added stability. Just ensure that the spikes are appropriately sized for the load of the pergola.