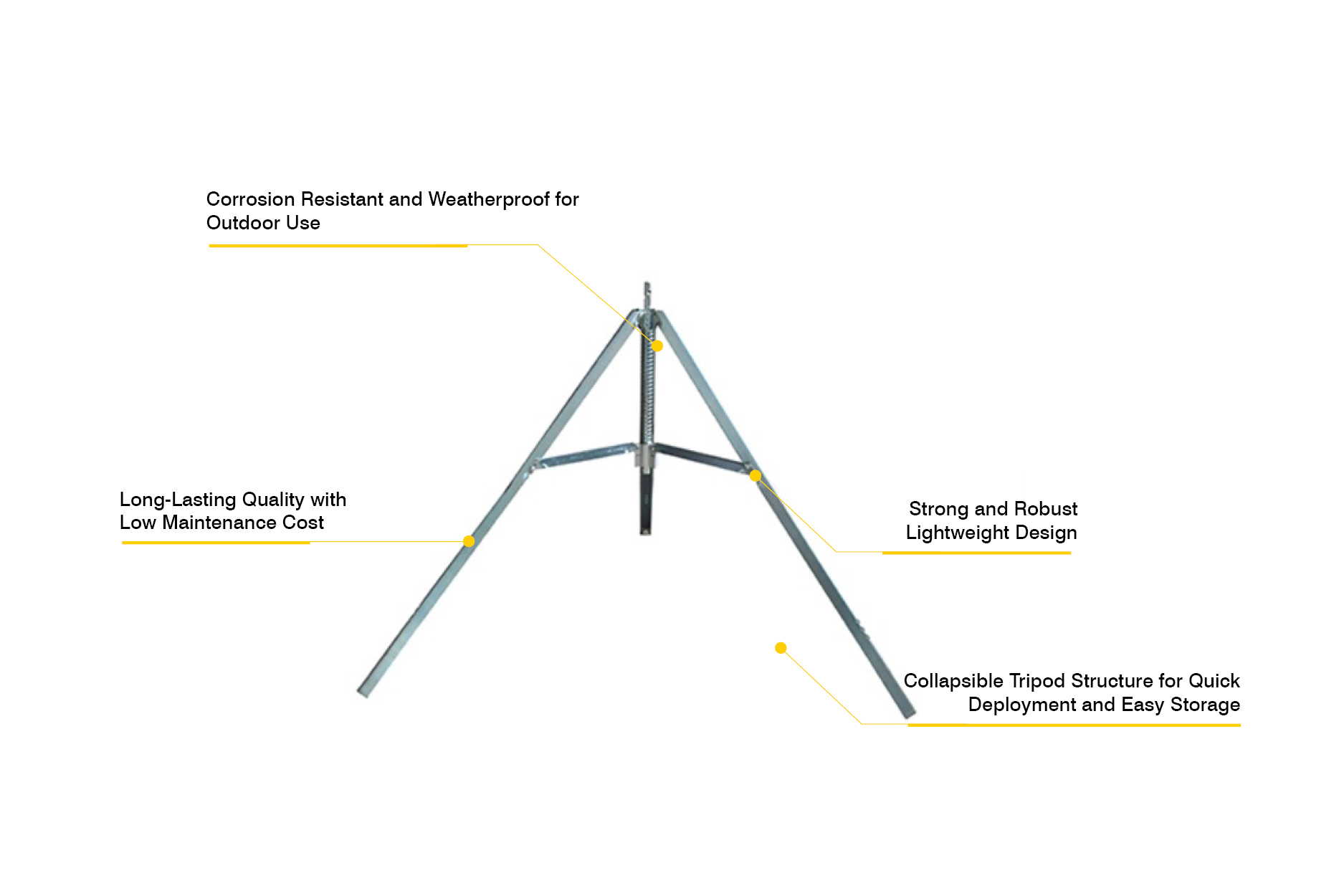

The OPTsigns Folding Traffic Sign Holder combines innovative design with practical functionality, making it an ideal choice for various outdoor applications. Featuring a collapsible tripod structure, this traffic sign holder is built for quick deployment and effortless storage, allowing you to set up your signs swiftly when needed. The steel folding traffic sign holder is made from corrosion-resistant materials, ensuring it can withstand the elements, making it a reliable tripod stand for outdoor signs. Its lightweight yet robust construction guarantees that it can handle demanding conditions without compromising durability.

The OPTsigns Folding Traffic Sign Holder combines innovative design with practical functionality, making it an ideal choice for various outdoor applications. Featuring a collapsible tripod structure, this traffic sign holder is built for quick deployment and effortless storage, allowing you to set up your signs swiftly when needed. The steel folding traffic sign holder is made from corrosion-resistant materials, ensuring it can withstand the elements, making it a reliable tripod stand for outdoor signs. Its lightweight yet robust construction guarantees that it can handle demanding conditions without compromising durability.

This tripod sign stand is perfect for temporary traffic control, work zone warnings, and construction site management. With its long-lasting quality and low maintenance cost, it stands out as a practical solution for managing road safety. This galvanized steel folding traffic sign holder offers exceptional sturdiness, while the versatility of the design makes it a popular choice among professionals. Whether you’re using it as a construction sign holder or a general traffic sign stand, this metal tripod stand for signs is engineered to meet the needs of various environments, ensuring optimal visibility and effectiveness in traffic management.

*We respect your confidentiality and all information are protected.

| Size | 600mm, 700mm, 900mm, 1100mm, Customizable |

|---|---|

| Material | Galvanized Steel |

| Option | Sign |

A traffic sign holder is a device used to securely support and display traffic signs. It provides stability and visibility for temporary or permanent signage, ensuring that important information is communicated effectively.

The height of a tripod sign holder typically ranges from 60 cm to 110 cm, as seen in OPTsigns models. This height allows for optimal visibility while ensuring compliance with local regulations. It’s important to position the sign at eye level for effective communication, especially in work zones or construction areas.

A camera stand is designed to support cameras and related equipment, focusing on stability for photography. In contrast, a tripod stand for signs is specifically engineered to hold signs securely, providing features like collapsibility and easy deployment, making it suitable for temporary uses such as construction sites.

Avoid using a folding traffic sign holder in high winds or extreme weather conditions without proper anchoring, as it may tip over. Additionally, do not exceed the weight limit or misuse it for signs not intended for tripod stands for signs, as this can compromise safety.

To assemble a steel folding traffic sign holder, first, unfold the tripod stand for signs and ensure the legs are fully extended. Next, attach the sign to the top bracket, securing it tightly. Finally, adjust the height if applicable, making sure it’s stable and ready for use.