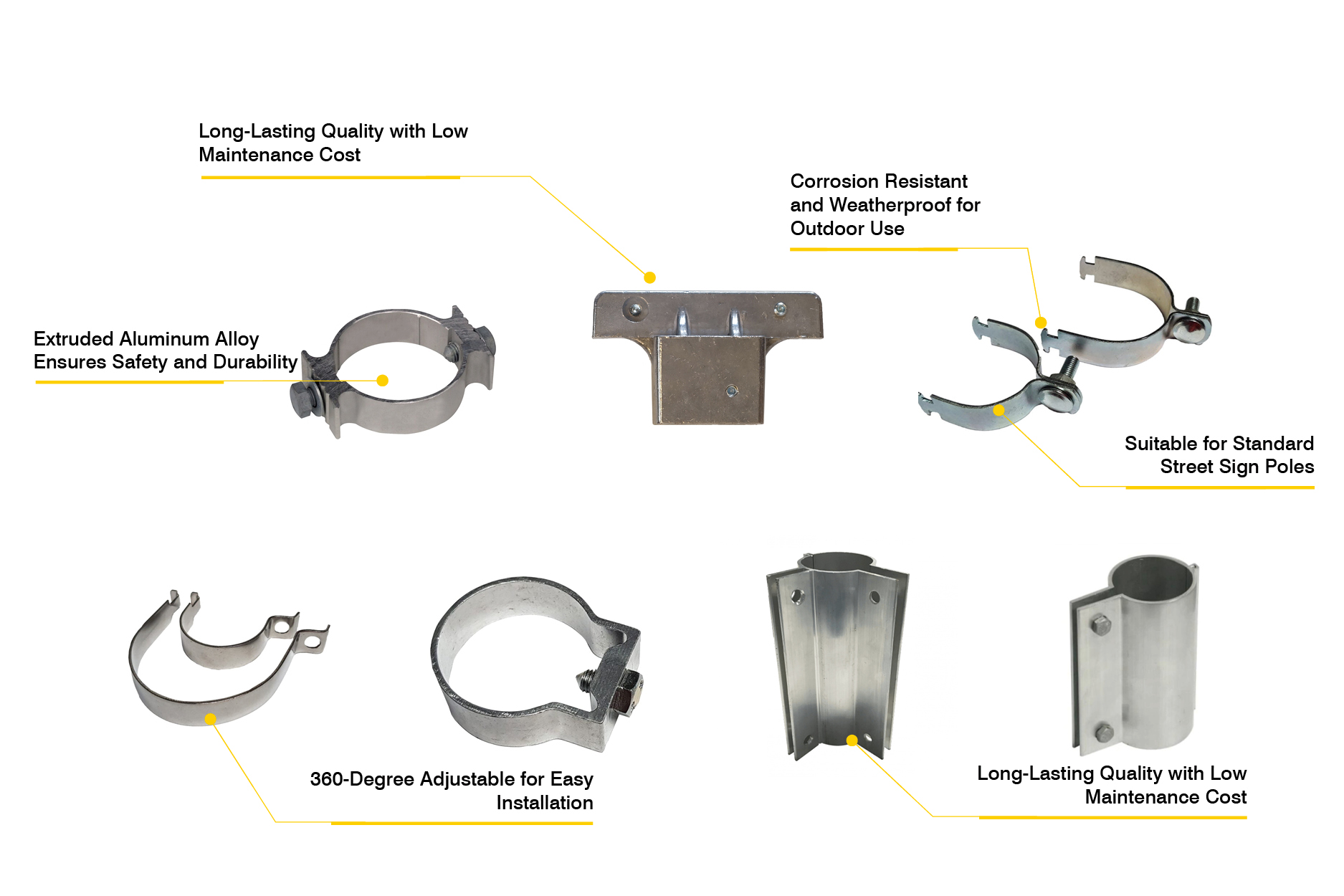

OPTsigns Extruded Street Name Brackets are designed with safety and durability in mind, ensuring long-lasting performance even in challenging outdoor conditions. Made from extruded aluminum alloy, these metal sign brackets are corrosion-resistant and weatherproof, making them ideal for various environments. The 360-degree adjustable feature allows for easy installation, enabling you to position street name signs in any direction. These square sign post brackets are also compatible with standard street sign poles, providing a secure and reliable mounting solution.

OPTsigns Extruded Street Name Brackets are designed with safety and durability in mind, ensuring long-lasting performance even in challenging outdoor conditions. Made from extruded aluminum alloy, these metal sign brackets are corrosion-resistant and weatherproof, making them ideal for various environments. The 360-degree adjustable feature allows for easy installation, enabling you to position street name signs in any direction. These square sign post brackets are also compatible with standard street sign poles, providing a secure and reliable mounting solution.

In addition to their robust construction, OPTsigns street name sign mounting brackets offer low maintenance costs, making them a practical choice for municipal and commercial applications. Their design accommodates square sign posts, ensuring versatility for different street sign needs. Whether you require a square post bracket or a standard sign bracket for post, these solutions provide the necessary support and stability. Choose OPTsigns for high-quality street sign post brackets that blend functionality with durability, enhancing the visibility and clarity of your street signage.

*We respect your confidentiality and all information are protected.

| Size | 60mm Dia. (2 3/8����), Customizable |

|---|---|

| Colour | Silver, Mill Finish |

| Material | Extruded Aluminum Alloy |

| Customize | Logo, Marking and Shape |

A street sign post bracket is a hardware component used to attach signage to a post securely. These brackets ensure that street name signs remain stable and visible, accommodating various types of posts, including round and square designs. Available in different materials, such as metal sign brackets, they provide essential support for street signage.

Aluminum post brackets are known for their strength and durability. They offer a high strength-to-weight ratio, making them suitable for supporting street name sign brackets in various weather conditions. With proper design and thickness, these brackets can withstand substantial loads, ensuring the stability of mounted signs.

The thickness of aluminum for brackets typically ranges from 1/8 inch to 1/4 inch, depending on the application. For most street name sign mounting brackets, a thickness of 1/8 inch is often sufficient, providing a balance between strength and weight while ensuring the sign bracket can handle outdoor stresses.

To use street sign post mounting brackets, first, position the bracket on the desired post height. Secure it using bolts or screws, ensuring it is level. Attach the street sign to the bracket, making sure it is stable. These sign mounting brackets allow for easy installation and adjustment, enhancing visibility.

The main difference lies in their design and compatibility. A square post street sign bracket is specifically designed to fit square posts, providing a snug fit, while a round post sign mounting bracket is tailored for cylindrical posts. Both types are effective as sign brackets for posts, but the choice depends on the post shape used.