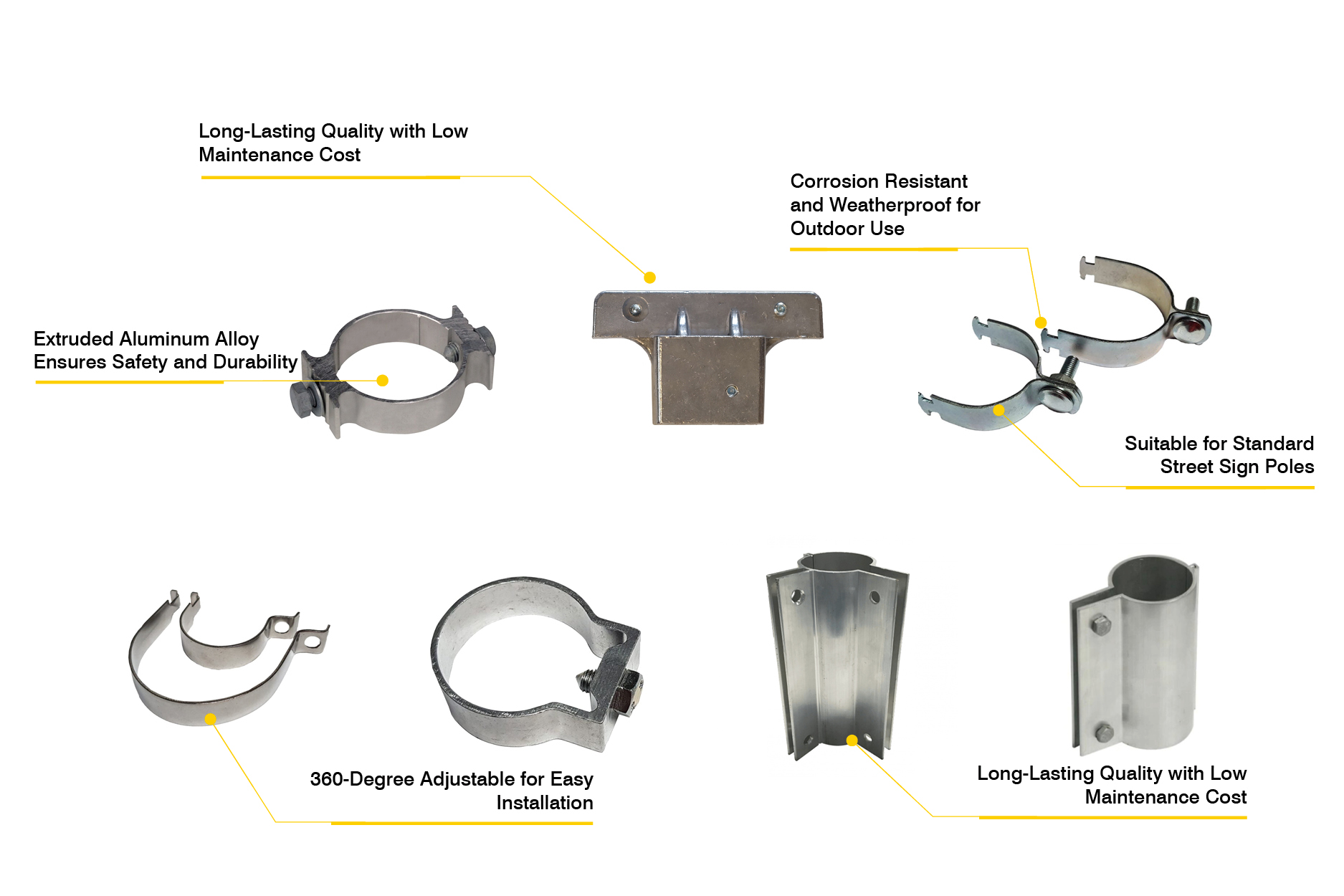

OPTsigns double-sided sign bracket is designed with an interlocking and adjustable system that expertly controls clamping pressure, making it ideal for installing safety signs on round post sign mounting brackets and fences. Constructed from high-quality extruded aluminum alloy, these sign post brackets ensure safety and durability. Their corrosion-resistant and weatherproof features make them suitable for outdoor use, while the 360-degree adjustable and bolt-on design allows for easy installation, enhancing the versatility of your signage solutions.

OPTsigns double-sided sign bracket is designed with an interlocking and adjustable system that expertly controls clamping pressure, making it ideal for installing safety signs on round post sign mounting brackets and fences. Constructed from high-quality extruded aluminum alloy, these sign post brackets ensure safety and durability. Their corrosion-resistant and weatherproof features make them suitable for outdoor use, while the 360-degree adjustable and bolt-on design allows for easy installation, enhancing the versatility of your signage solutions.

With long-lasting quality and low maintenance costs, these sign brackets for posts are perfect for standard street sign poles, ensuring your safety messages remain visible and secure. Whether you’re using them as sign brackets for round posts or aluminum mounting brackets, OPTsigns’ innovative design and robust materials make them a reliable choice for any signage application. Trust these metal sign brackets to provide the durability and functionality needed to maintain effective communication in your community.

*We respect your confidentiality and all information are protected.

| Size | 50mm Dia., 60mm Dia., Customizable |

|---|---|

| Colour | Silver, Mill Finish |

| Material | Extruded Aluminum Alloy |

| Customize | Logo, Marking and Shape |

To use dynabolts, first select the appropriate size based on your project’s needs. Refer to the dynabolt installation guide for detailed instructions. Ensure the installation surface, like concrete, is clean and free of debris. Place the galvanized dynabolts through the fixture and into the pre-drilled hole, then tighten using a suitable tool.

Dynabolts function by expanding within a pre-drilled hole when tightened, creating a secure anchor. This expansion mechanism allows them to hold substantial loads. The stainless steel dynabolts are particularly effective in resisting corrosion, ensuring a long-lasting hold in various environments.

To install a dynabolt, first drill a hole into the concrete of the appropriate size. Insert the dynabolt into the hole, ensuring it is aligned with the fixture. Use a wrench to tighten the nut, which will cause the dynabolt to expand and grip the surrounding material securely. Follow the dynabolt installation guide for specific instructions based on the type used.

To remove dynabolts from concrete, first, unscrew the nut and washer. Then, use a hammer to gently tap the dynabolt, loosening it from the concrete. If it resists, you may need to drill further into the hole or use a wrench to rotate the galvanized dynbolt counterclockwise until it releases.

The weight a dynabolt can hold varies based on its size and the material it is anchored into. Generally, standard galvanized dynabolts can support significant loads when properly installed.