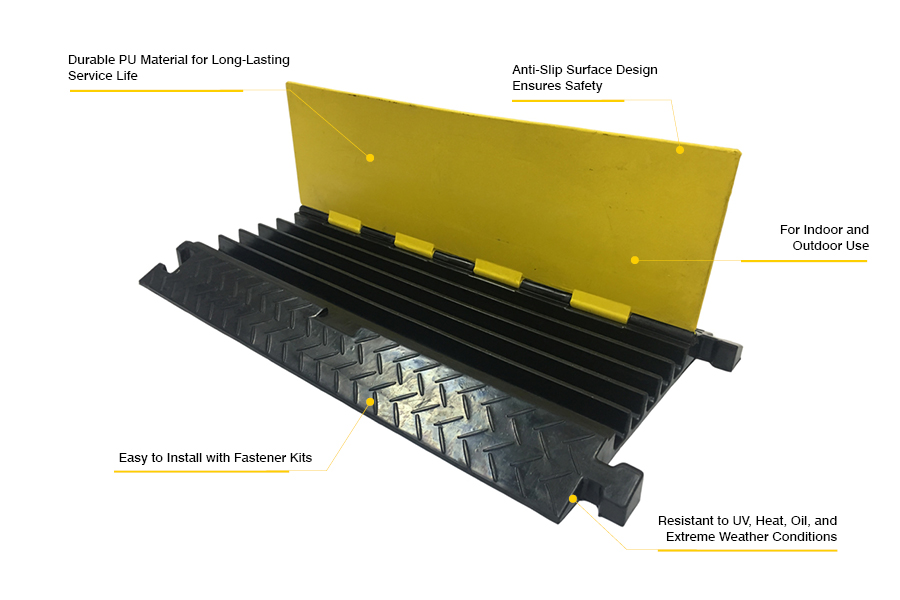

Optsigns Cable Channels are expertly crafted from high-quality PU material, designed to be impact and temperature resistant, ensuring exceptional durability in demanding environments. These heavy-duty cable protectors provide a safe and effective solution for protecting wires, cables, and cords in areas exposed to heavy vehicles or high foot traffic. By minimizing the risk of damage, these cable channels help maintain safety and organization in workplaces, construction sites, events, and other bustling environments where cables need to be securely managed.

Optsigns Cable Channels are expertly crafted from high-quality PU material, designed to be impact and temperature resistant, ensuring exceptional durability in demanding environments. These heavy-duty cable protectors provide a safe and effective solution for protecting wires, cables, and cords in areas exposed to heavy vehicles or high foot traffic. By minimizing the risk of damage, these cable channels help maintain safety and organization in workplaces, construction sites, events, and other bustling environments where cables need to be securely managed.

*We respect your confidentiality and all information are protected.

| Size (2 Channels) | 1000*250*45mm(��35), 1000*250*50mm(��35) |

|---|---|

| Size (5 Channels) | 900*500*55mm(��30), 900*500*55mm(��35) |

| Material | PU Base with PE Cover |

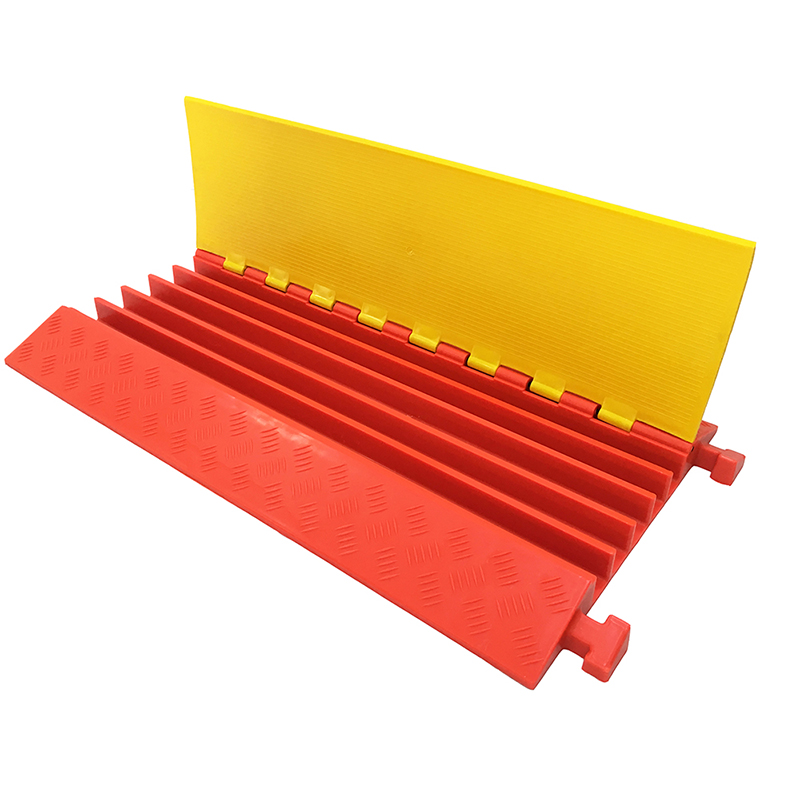

| Colour | Red & Yellow, Black & Yellow |

| Load Capacity | 15t |

| Customize | Custom Size and Weight |

Using Optsigns cable protector is straightforward and efficient for safeguarding your cables. Start by placing the cable protector over the wires, cords, or cables you wish to protect. Ensure that the cable protector covers the entire length of the cables to prevent tripping hazards and damage. Position the cable protector in high-traffic areas, such as walkways, construction sites, or any location with vehicle access. Regularly check the cable protector for any signs of wear or damage to ensure optimal protection for your cables and cords.

Barrier fences are temporary or permanent structures designed to control access, protect pedestrians, and guide traffic. They are often used at construction sites, events, or parking lots. Plastic barrier fences are lightweight, durable, and can be customized for various applications like crowd control barrier fences.

To install a safety barrier fence, ensure the ground is leveled, secure posts at regular intervals, and attach the fence panels. Follow the manufacturer’s guidelines, especially for construction site barrier fences.

A fence barricade serves to restrict access, guide pedestrian or vehicle movement, and ensure safety at locations like construction sites and public events. Crowd control barrier fences are often used to manage people, while road fence barriers help regulate traffic.

Construction sites cover their fence barriers for privacy, safety, and dust control. The covering prevents unauthorized access and reduces the visibility of ongoing work. It also enhances safety by keeping debris contained and blocking distractions to nearby traffic or pedestrians. Often, construction site barrier fences are covered with mesh or solid panels for these purposes.

The fence of a construction site is typically a construction site barrier fence used to secure the area and restrict unauthorized access. Usually made from materials like plastic, wood, or metal, this kind of safety barrier fence ensures protection for workers and the public.