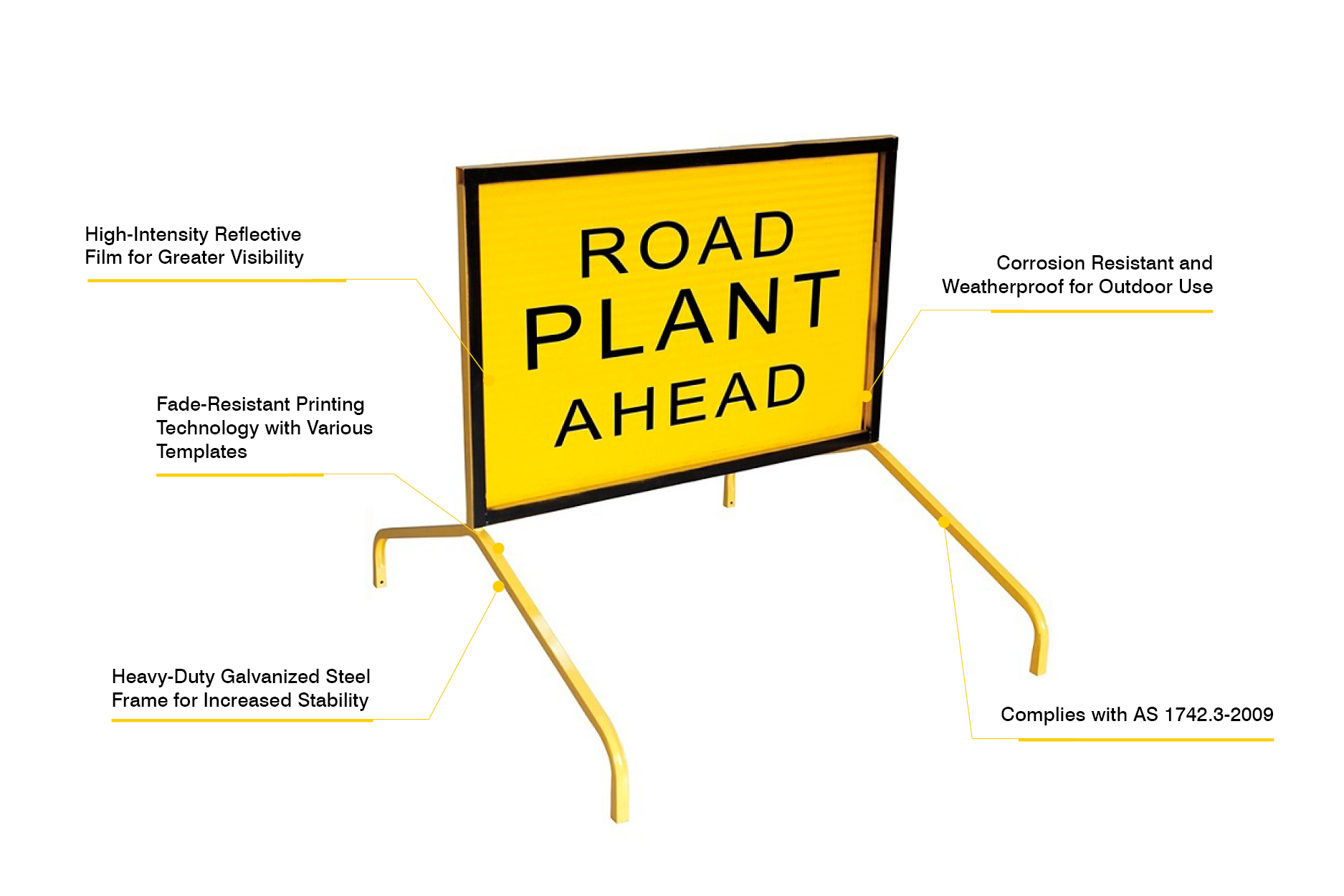

Optsigns Boxed Edge Signs are expertly crafted from galvanized steel plate, ensuring durability and resistance to rust and corrosion. With a bright yellow powder coating finish and Class 1 reflective film, these temporary road signs provide excellent visibility day and night. Designed to effectively manage traffic, temporary road signs are commonly used to alert motorists to roadworks, roadway closures, speed reductions, and other hazardous road conditions. Their robust construction and high reflectivity make temporary road signs an ideal choice for maintaining safety in various environments.

Optsigns Boxed Edge Signs are expertly crafted from galvanized steel plate, ensuring durability and resistance to rust and corrosion. With a bright yellow powder coating finish and Class 1 reflective film, these temporary road signs provide excellent visibility day and night. Designed to effectively manage traffic, temporary road signs are commonly used to alert motorists to roadworks, roadway closures, speed reductions, and other hazardous road conditions. Their robust construction and high reflectivity make temporary road signs an ideal choice for maintaining safety in various environments.

*We respect your confidentiality and all information are protected.

| Size | 600*600mm, 900*600mm, 1200*300mm, 1200*450mm, 1200*600mm, 1200*900mm, 1500*300mm, 1500*450mm, 1500*600mm, 1500*750mm, 1500*900mm, 1800*300mm, 1800*450mm, 1800*600mm, 1800*750mm, 1800*900mm, 1800*1200mm, 2400*900mm, 2400*1200mm |

|---|---|

| Thickness | 0.8mm Steel Plate |

| Edge | 25*25mm with Black Film |

| Material | Galvanized Steel Plate with Engineering Grade/Class 1 Reflective Film |

| Finish | Yellow Powder Coating |

| Customize | Custom Text, Logo, Film Grade and Legs |

Using Optsigns Boxed Edge Sign is straightforward. Position the Boxed Edge Sign in a location where it is clearly visible to drivers, such as near roadworks, construction zones, or areas requiring speed reduction. Ensure the Boxed Edge Sign is upright and securely mounted to withstand wind and weather conditions. Regularly check the visibility and condition of the Boxed Edge Sign to ensure it effectively communicates important information to motorists, enhancing road safety.

Boxed Edge Signs are constructed from galvanized steel plate, which provides strength and durability. Boxed Edge Signs are finished with a yellow powder coating for added protection against the elements and enhanced visibility.

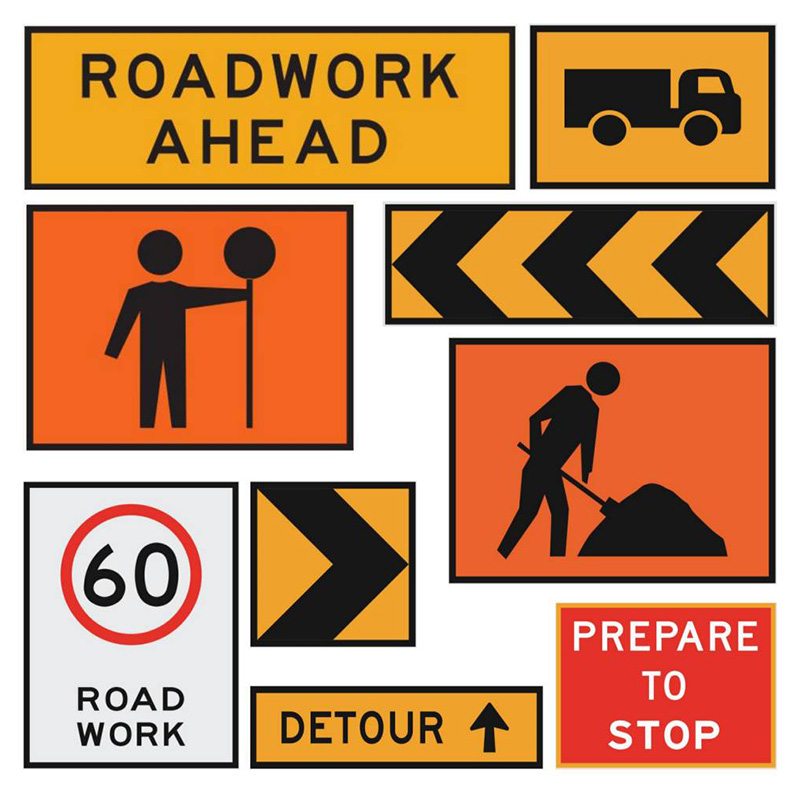

Traffic regulations are conveyed in signs that are rectangular with the longer direction vertical or square. Additional regulatory signs are octagons for stop and inverted triangles for yield. Diamond-shaped signs signify warnings. Rectangular signs with the longer direction horizontal provide guidance information.

Class 1 reflective film is used on Boxed Edge Signs to ensure high visibility in low-light conditions. This reflective property helps drivers notice the Boxed Edge Signs from a distance, increasing safety during nighttime and adverse weather.

Boxed Edge Signs are versatile and can convey various messages, including warnings for roadworks, roadway closures, speed reductions, and other hazardous conditions. This makes them essential for effective traffic management.

By providing clear and visible warnings to motorists,yellow boxed edge signs help prevent accidents and enhance overall road safety. Their reflective properties ensure that the messages are seen even in low-light conditions.

Yes, yellow boxed edge signs are specifically designed for outdoor use. Their galvanized steel construction and weather-resistant yellow powder coating ensure durability and effectiveness in various environmental conditions.

Absolutely! Boxed Edge Signs are ideal for construction zones as they effectively alert drivers to potential hazards, helping to manage traffic flow and enhance safety for both workers and motorists.