調達マネージャーと交通プランナーは、購入すると混乱することがよくあります 交通標識 他の国のプロジェクトの場合. オーストラリアと米国で使用される反射シートクラス. 大きく異なります. これらにはクラスが含まれます 1, クラス 2, とクラス 3 オーストラリアで, エンジニアグレードと比較してください, 高強度, 米国のダイヤモンドグレード. このような違いは、兆候の選択とその有効性に影響します. 調査によると、標識でより良い反射シートを使用すると、夜間の事故を減らすことができることが示されています。 30%. 適切な標識を選択すると、視認性が向上し、交通安全が向上します, 特に交通量が多い地域で. 署名メーカーと交通安全の専門家は、規制に準拠する交通標識を購入し、すべての道路利用者の安全を確保するために、これらのクラスの区別を理解する必要があります.

反射シートクラス

オーストラリア対. 私たち. 基準

オーストラリアと米国は、交通標識の反射シートを整理するためにさまざまな方法を使用しています. オーストラリアで, the As/nzs 1906 標準には、3つの主要なクラスがリストされています: クラス 1, クラス 2, とクラス 3. これらのクラスは、さまざまな兆候に対してシートがどれほど明るくて困難である必要があるかを示しています. クラス 1 ほとんどの通常の道路標識でうまく機能します, しかし、クラス 3 最も明るく、重要な場所で使用されています.

米国はMUTCD標準を使用しています. エンジニアグレードのような名前があります, 高強度, ダイヤモンドグレード. エンジニアグレードは、それほど重要ではない兆候のためです. 高強度とダイヤモンドグレードは明るく、主な標識や忙しい道路に使用されます.

注記: どちらの標準も、交通標識を購入するときに可視性を確保します, しかし、用語と輝度測定が異なります.

重要な違い

最大の違いは、各システムがグレードをソートする方法です. オーストラリアは数字を使用しています, しかし、米国. 名前を使用します. これにより、他の国の標識に適切なシートを選ぶのが難しくなります.

| 反射グレード | オーストラリア (As/nzs 1906) | 私たち. (mutcd) |

|---|---|---|

| エントリーレベル | クラス 2 | エンジニアグレード |

| ミッドレベル | クラス 1 | 高強度 |

| プレミアム | クラス 3 | ダイヤモンドグレード |

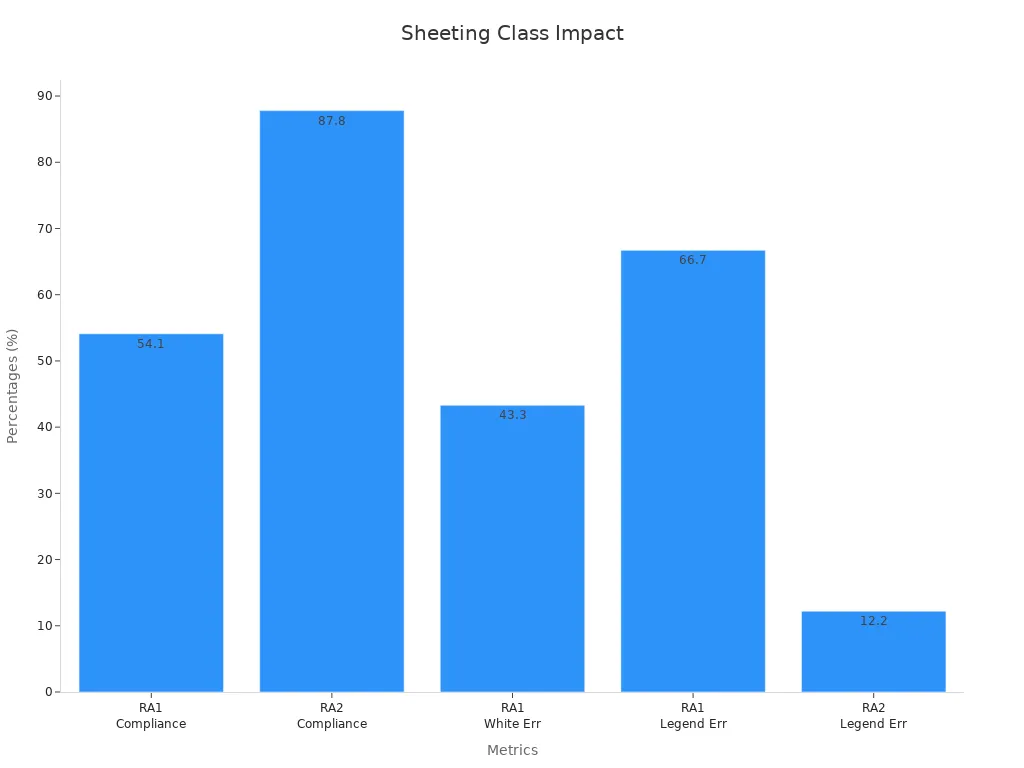

研究はRA2を示しています (高強度のように) RA1よりも簡単に見ることができます (エンジニアグレードのように). RA2サインは明るく、ドライバーがルールをよりよく守るのに役立ちます. 例えば, RA2白い兆候は、同じくらい明るくすることができます 180 cd・lx⁻¹・m⁻², しかし、Ra1はに達するだけです 50 cd・lx⁻¹・m⁻². これは、RA2の標識を見つけるのが簡単になることを意味します, 特に夜に.

一般的な誤解

他の国でプロジェクトの標識を購入する人は、成績を混同することがあります. 彼らは重要な兆候のために高強度ではなくエンジニアグレードを選択するかもしれません, これにより、兆候が見えなくなります. 明るさが下に落ちた場合 100 cd・lx⁻¹・m⁻², ドライバーは標識をよく見ないかもしれません. 悪天候とまぶしさはこの問題を悪化させる可能性があります.

ヒント: 交通標識を購入する際には、ローカルルールと道路のニーズに適した反射シートクラスを常に使用してください. これは、すべての人を安全に保ち、法律に従うのに役立ちます.

トラフィックサインの可視性への影響

反射率とパフォーマンス

反射シートは、ドライバーが交通標識をよりよく見るのに役立ちます. 反射シートのクラスは、サインがどれほど明るいかを変えます. よりクラスの反射シート, クラスのように 3 またはダイヤモンドグレード, もっと輝いています. これらの標識は遠くから車のヘッドライトの下から見ることができます. これは、忙しい道路の安全性にとって非常に重要です. 下層階級の反射シート, クラスなど 2 またはエンジニアグレード, それほど明るくはありません. これらの兆候は、暗くなっているときや雨が降っているときに見るのが難しいです. 間違ったクラスが使用されている場合, ドライバーは重要な兆候を見逃すかもしれません. これにより、標識を読むのが難しくなり、より多くの事故を引き起こす可能性があります. 視認性が良好で兆候が際立っています, 忙しい道路でも.

注記: 交通標識を購入するときに適切な反射シートを選ぶ. これは、すべての人を路上で安全に保つのに役立ちます.

環境要因

天気と気候は、反射シートがどの程度うまく機能するかを変える可能性があります. 熱のようなもの, 雨, そして、日光はシートをより速く摩耗させることができます. 非常に暑いまたは雨の多い場所で, 標識はそれほど長く続かないかもしれません. これにより、標識が明るくなく、安全性が低下する可能性があります. 研究は、反射的なコーティングが建物をより涼しく保ち、エネルギーを節約するのに役立つことを示しています. 下の表は、オーストラリアのさまざまな地域で見つかったものを示しています:

| 側面 | 調査結果 |

|---|---|

| 温度低下 | 屋内空気が立ち上がった 5.8 反射コーティング付きの°Cクーラー. |

| 省エネ | 省エネはそうでした 31.9 シドニーのkWh/m²・y, 60.6 アリススプリングスのkWh/m²・y, そして 85.6 ダーウィンのkWh/m²・y. |

| 熱快適性の改善 | 熱波の不快感が立ち寄りました 100% シドニーで, 86.7% アリススプリングスで, そして 92.6% ダーウィンで. |

| 冷却エネルギー需要 | 冷却エネルギーの使用はまで減少しました 80.6%. |

| ピーク負荷シフト | ピーク負荷はまで移動しました 71 オフピーク時間から数分. |

| 経済回収期間 | 回収時間はその間でした 5.3 そして 24 年, 気候に応じて. |

| 気候の影響 | 反射シートがどれだけうまく機能するかは、天気に依存します. |

これらの結果は、天候が反射シートがどの程度うまく機能するかを変える可能性があることを示しています. 暑い場所または濡れた場所で, 標識は、明るく長持ちするためにより高いクラスのシートが必要になる場合があります. 厳しい天気の兆候は、人々を安全に保つために強力な素材を必要とします.

交通安全への影響

反射シートの間違ったクラスを使用することは危険です. 十分に明るくない兆候は、ドライバーに時間内に警告しない場合があります. これは、交差点や学校の近くの場所で大きな問題です. ドライバーは標識をすぐに読むことができません, クラッシュを引き起こす可能性があります. 良い反射シートは、常に兆候を簡単に見ることができます. 高品質のシートは兆候をより明確にし、ドライバーが速く反応するのに役立ちます. これは、ヘッドライトが唯一の光である夜に非常に重要です.

ヒント: 道路と交通に適したクラスの反射シートを常に選択してください. これにより、あらゆる状況で兆候が明確で簡単に見ることができます.

間違ったシートが使用されている場合, 標識は見にくく、安全性が低くなる可能性があります. 重要な道路の場合, 緊急ルートや高速道路のように, 最良の反射シートのみを使用する必要があります. これにより、すべての人が安全に保たれ、交通がうまく動くのに役立ちます.

交通標識を購入するときの調達課題

一般的な間違い

多くの調達マネージャーは、他の国のために標識を購入するときに混乱します. 彼らは時々反射シートクラスを混同します. 例えば, 主要道路のピックエンジニアグレードもあります. しかし、これらの道路にはダイヤモンドグレードのような明るい標識が必要です. この間違いは、夜に兆候を見るのが難しくなります. 一部のチームは、トラフィックコントロールデバイスに間違った反射素材を使用しています. これらのエラーは標識を目に見えなくし、人々を危険にさらします.

ヒント: 交通標識を注文する前に、必ず地域の基準を確認してください. これは間違いを避け、交通制御装置をうまく機能させ続けるのに役立ちます.

コストとコンプライアンス

反射シートクラスの価格の違いは、バイヤーを驚かせることができます. ダイヤモンドグレードのような高級素材は低いものよりも高くなります. より安いオプションを選んでお金を節約しようとする人もいます. しかし、これはルールに従うことに問題を引き起こす可能性があります. サインがローカルルールを満たしていない場合, プロジェクトは罰金を科されるか、新しい兆候が必要になる場合があります. これにより、プロジェクトのコストが高まり、時間がかかります. 次の基準は、法律だけではありません. また、人々を道路上で安全に保ちます.

| 反射クラス | 典型的な使用 | コストレベル | コンプライアンスリスク |

|---|---|---|---|

| エンジニアグレード | 低トラフィックエリア | 低い | 高い |

| 高強度 | 主要道路 | 中くらい | 中くらい |

| ダイヤモンドグレード | 高速道路 | 高い | 低い |

サプライヤーの調整

サプライヤとの協力は、適切な交通標識を購入するために非常に重要です. チームはサプライヤーとはっきりと話し、プロジェクトとローカルルールに合った標識を取得する必要があります. 優れたコミュニケーションは、反射シートクラスとトラフィックコントロールデバイスで間違いを止めるのに役立ちます. 優れたサプライヤーは、各サインに最適な反射資料についてアドバイスをします. 彼らはまた、標識がルールに従うという書類と証拠を手伝います. このチームワークは、すべての標識が安全で見やすいことを確認します.

注記: 良いサプライヤー関係は、プロジェクトがうまくいき、長い間兆候を働かせ続けるのを助けます.

交通標識を購入するときに反射シートを選択します

他の国の交通標識のための適切な反射シートを選択するには、明確な計画が必要です. すべてのプロジェクトは異なります. 地元のルールと天気は物事を難しくすることができます. このガイドは、交通標識に最適な反射シートを選択する際に考えるべき主な手順と考えるべきことを示しています.

プロジェクトのニーズの評価

チームは、交通標識が何をしなければならないかを知る必要があります. 反射シートは、標識を見やすくする必要があります, 夜や悪天候でも. 反射フィルムは車のヘッドライトを跳ね返します. これにより、ドライバーは標識を見つけ、道路をより安全に保つのに役立ちます. 標識も長く続く必要があります. 彼らは厳しい場所を扱わなければなりません, 忙しい都市や遠い田舎道のように.

市場調査では、確認すべき重要なことをいくつか指摘しています:

| 重要な考慮事項 | 説明 |

|---|---|

| 視界と安全性 | 反射材料は、人々が夜または低照度で兆候を見るのに役立ちます. これは安全のために非常に重要です. |

| 規制のコンプライアンス | 材料は、各国の厳格な交通安全規則に従わなければなりません. |

| 耐久性と気象抵抗 | シートは長持ちするはずです, 悪天候でも. |

| 技術の進歩 | マイクロプリズムシートのような新しいものは、サインを明るくし、スマートシティシステムで動作する. |

| 地域市場のダイナミクス | ルール, 天気, そして、構築プロジェクトは各場所で異なります. これは、どの材料が最適かを変更します. |

| 材料セグメンテーション | 一部のシートは反射的です, いくつかはそうではありません. 選択は、それがどこでどのように使用されるかによって異なります. |

| アプリケーションフォーカス | ほとんどの需要は交通標識に対するものです. これらには強い必要があります, ルールに続く明るいシート. |

| 持続可能性の傾向 | より多くの人々が環境に優しいことを望んでいます, 生分解性, 環境に役立つリサイクル可能な材料. |

チームは道路を使用する車の数を考える必要があります, それはどんな道ですか, そして、サインがどれくらい続くべきか. 忙しい道路や重要な交差点には、最高の反射シートが必要です. 静かな道路は、より低いグレードを使用できます. ドライバーが速く決定できるように、標識は常に読みやすい必要があります.

ヒント: 地元の天気を確認してください. とても暑い, 雨, または晴れた場所は反射材料をより速く摩耗させることができます. 天気に合ったシートを選択してください.

クラスを環境に一致させる

反射シートの適切なクラスは、サインがどこに行くかによって異なります. 各クラスは異なるレベルの明るさを与え、それがどれくらい続くか. チームは、反射性グレードを道路に一致させる必要があり、それがどれほど忙しいか.

- 都市部: たくさんの人と車がいる忙しい通りは、目立つ兆候が必要です. クラス 1 または、高強度シートはここでうまく機能します.

- 高速道路と主要な道路: 速い交通と長距離には、最も明るい兆候が必要です. クラス 3 または、ダイヤモンドグレードのシートがこれらの道路に最適です.

- 農村部または低トラフィックの道路: これらの道路はクラスを使用できます 2 またはエンジニアグレードシート. 十分に明るく、コストが安くなります.

- 特別な環境: 建物のような場所, 学校, または緊急ルートは、すべての人を安全に保つために最適な反射シートを必要としています.

適切な反射グレードを選択します, チームは、各道路に必要なものを調べる必要があります. 乱暴な天候や多くの使用のある場所の標識は、長持ちするためにマイクロプリズム技術が必要になる場合があります.

注記: プロジェクトエリアの交通標識の最新のルールを常に確認してください. これにより、反射シートがうまく機能し、法律に従うことが確認されます.

標準コンプライアンスの確保

ローカルおよび世界の基準に従うことは、すべてのトラフィックサインプロジェクトにとって非常に重要です. チームは、すべての反射シートが正しいルールを満たしていることを確認する必要があります. 良い記録を保つことはこれの大きな部分です.

- フォームTrのような証明書-0030 一時的な交通規制デバイスがクラッシュで安全であることを示してください.

- 承認された材料リストは、すべての標識が適切な反射シートを使用することを確認するのに役立ちます.

- いくつかの兆候は、連邦高速道路局の受け入れの手紙が必要です.

- 建設エリアサインはタイプを使用する必要があります 3 または、信頼できるメーカーからのより良いレトレレフェクティブシート.

- チェックと検査では、標識がメーカーと法律のルールの両方を満たしていることを確認してください.

グループは多くの場合、独自のチェックとレビューを行い、ルールに従うことを確認します. これらのチェックは、問題を見つけて物事を改善するのに役立ちます. ISO 45001 外部の専門家による監査は、規則が満たされ、書き留められていることを余分に証明します.

ヒント: すべてのコンプライアンスペーパーをきちんと見つけやすいままにしてください. これは将来のチェックに役立ち、プロジェクトをスムーズに行かせます.

交通標識の反射シートを選択することは、タイプを選ぶだけではありません. チームは、サインを見るのがどれほど簡単かを考えなければなりません, どれくらい続くでしょうか, ルール, そして天気. 明確な計画に従うことによって, 彼らはすべてのサインが安全であり、うまく機能していることを確認することができます.

交通標識を購入するときの国境を越えたプロジェクトのベストプラクティス

段階的なプロセス

簡単な計画は、チームが他の国から交通標識を購入するのに役立ちます. 初め, プロジェクトマネージャーは、両方の場所で反射シートのためのローカルルールを見つける必要があります. 次, 彼らはサプライヤーにプロジェクトに必要なものを伝えます, だから誰もが何を期待するかを知っています. その後、チームはサプライヤが資格があるかどうかを確認し、ルールに一致するサンプルを要求します. この後, 彼らはすべての論文を見ます, 証明書や記録のように, すべてが正しいことを確認します. 最後に, チームは、サプライヤとの定期的な会議を設定して、物事がどのように進んでいるかについて話し、問題を迅速に修正する.

| ステップ | アクション | 目的 |

|---|---|---|

| 1. 標準を特定します | ローカルおよび国際的なルールを調査します | 正しい反射シートクラスを確認してください |

| 2. 信号需要 | サプライヤーとプロジェクトのニーズを共有します | 誤解を避けてください |

| 3. サプライヤーを確認します | 資格情報を確認し、サンプルをリクエストします | 品質とコンプライアンスを確認します |

| 4. ドキュメントを確認します | 証明書とコンプライアンスレコードを調べます | 法的要件を満たします |

| 5. 継続的な会議 | 定期的なサプライヤーの議論を行います | 早期に問題に対処します |

落とし穴を避けます

他の国でプロジェクトの交通標識を購入するのは難しい場合があります. チームは間違った反射シートクラスを選ぶか、重要な手順を忘れるかもしれません. これらの間違いを止めるため, チームはサプライヤーと早期に話し合い、明確な言葉を使用する必要があります. 中国からの物語は、その強い要求を示しています, スキルの証明, そして、会議はしばしばサプライヤーが何が必要かを知るのに役立ちます. チームにはすべての人も含める必要があります, 地元の指導者や道路を使用する人々のように, 正しい兆候が選択されていることを確認します.

ヒント: 早めに話し、フィードバックを与えることはしばしば大きな間違いを止め、プロジェクトをうまく動かし続けます.

ドキュメントと認定

正しい論文を持つことで、交通標識がオーストラリアと米国の両方に従うことを確認する. ルール. チームは次のような証明書を収集する必要があります ASTM D4956 米国のために、オーストラリアのルールもチェックしてください. The mutcd また、州のガイドは、どの反射シートが許可されているかをチームが知るのにも役立ちます. すべての論文を維持する整頓は、チームが小切手や訪問中にルールに従うことを示すのに役立ちます.

| 認定基準 / ドキュメント | 説明 | コンプライアンス地域 |

|---|---|---|

| ASTM D4956 | トラフィックコントロールデバイスの再lective反射シートの標準 | 米国 |

| mutcd | 交通管制装置の連邦ガイダンス | 米国 |

| Mn mutcd | サイン分類のための州レベルのマニュアル | 米国 |

注記: チームは常に証明書と記録を最新の状態に保ち、プロジェクトがスムーズに進むのを支援する必要があります.

さまざまな反射シートクラスは、人々をグローバルプロジェクトで混乱させることができます. チームは、資料を選ぶ前にローカルルールを検討する必要があります. クラスを比較するためにガイドを使用する必要があります. 地元のサプライヤーと協力すると、誰もがルールに従うのに役立ちます. また、交通標識を購入するときにニーズについて話すことがはるかに簡単になります. サプライヤーとのトレーニングと話すことは、多くの場合、チームがより良い選択をするのに役立ちます. チームがこれらのことをする場合, プロジェクトはより良くなり、道路は誰にとっても安全になります.

よくある質問

オーストラリアと米国の主な違いは何ですか. 反射シートクラス?

オーストラリアはクラスを使用しています 1, クラス 2, とクラス 3 サイン用. 米国. エンジニアグレードを使用します, 高強度, ダイヤモンドグレード. 各国は独自の方法で明るさと強さをチェックします. これは、他の国と協力するときに物事を混乱させる可能性があります.

正しい反射シートクラスを選択するのはなぜですか?

適切な反射シートを選ぶと、兆候が見やすいままになるのに役立ちます. 間違ったクラスを使用する場合, 兆候は夜や雨の中を見つけるのが難しいかもしれません. これにより、事故を引き起こし、現地のルールを破る可能性があります.

国際的に交通標識を購入するとき、調達チームはどのように間違いを避けることができますか?

チームは、標識を購入する前に常にローカルルールを見る必要があります. 彼らはサプライヤーとはっきりと話し、標識がルールに従うことの証拠を求める必要があります. 反射クラスは、サインが進む道路に適合する必要があります.

どの反射シートクラスが高速道路に最適です?

米国のダイヤモンドグレード. またはクラス 3 オーストラリアでは、高速道路に最適です. これらのクラスは最も明るく、最も長く続きます. 彼らは忙しい道路で全員を安全に保つのに役立ちます.

どのような文書が反射的なシート基準へのコンプライアンスを証明しています?

| ドキュメントタイプ | 地域 |

|---|---|

| ASTM D4956証明書 | 米国 |

| As/nzs 1906 証明書 | オーストラリア |

| MUTCDの承認 | 米国 |

これらの論文は、反射シートが正しい基準を満たしていることを示しています.