のようなトップ企業 テスラ そして アマゾン スマートツールを新しいアイデアと混合することで成功します. 彼らはマシンを使用します, 安全システム, 柔軟性を維持するための環境に優しい方法. 例えば, ライブトラッキングとスマート予測を使用して、負傷を削減します 25% 1年で. また、自動化されたレポートは、次のミスレポートを増加させます 60%, 安全習慣の改善. セーフティコーンやサインなどのシンプルなツールをハイテクギアと組み合わせることにより, これらの企業は、産業をリードしながら、より安全かつ速く仕事をしています.

信頼できるトラフィックサプライヤーとして, オプトラフィック シームレスに最新の安全システムにシームレスに統合する高品質の安全コーンと標識を提供します. 機体トラフィックセーフティコーンと標識は耐久性のために構築されています, 可視性, コンプライアンス - ヘルピング企業は、求人サイト全体の安全性と効率を向上させます, 倉庫, と道路.

Oprafficが信頼できる安全標識とコーンソリューションの頼りになるサプライヤーである理由を発見するために、今日お問い合わせください.

キーテイクアウト

- テスラやアマゾンのような大企業は、安全性と作業速度を向上させるためにスマートテックを備えたシンプルなツールを使用しています.

- ツールを使用することで、企業は変化に迅速に調整するのに役立ちます, 仕事を改善し、リソースを節約します.

- 新しい技術, IoTセンサーや自動レポートのように, 事故を削減し、労働者を幸せにします.

- 安全計画を立てることで、怪我を減らし、スマートツールを使用して問題を早期に報告することにより、職場をより安全にすることができます.

- さまざまなアイデアを混ぜるとうまくいきます, 創造的で柔軟であることは、あらゆるビジネスの成功につながることを示す.

トップエンタープライズにおける機器の組み合わせの哲学

なぜトップエンタープライズが機器の組み合わせと柔軟性に焦点を合わせているのか

テスラやアマゾンのような大企業は柔軟なツールに焦点を当てています. これは、彼らが変化する市場で強く滞在するのに役立ちます. 柔軟性があることは、突然の変化を簡単に処理できることを意味します. 例えば, 市場が変化するとき, 彼らはすぐに彼らがどのように機能するかを調整します. 柔軟なプランを使用すると時間を節約し、リソースをよりよく使用します.

| 柔軟性の主な理由 | 柔軟性の利点 |

|---|---|

| 高速市場の変更には、迅速な対応が必要です. | より速い生産調整. |

| 競争力のある維持は迅速なアクションを必要とします. | ツールと材料のより良い使用. |

| リソースの節約は非常に重要です. | その過程で未完成の作業が少ない. |

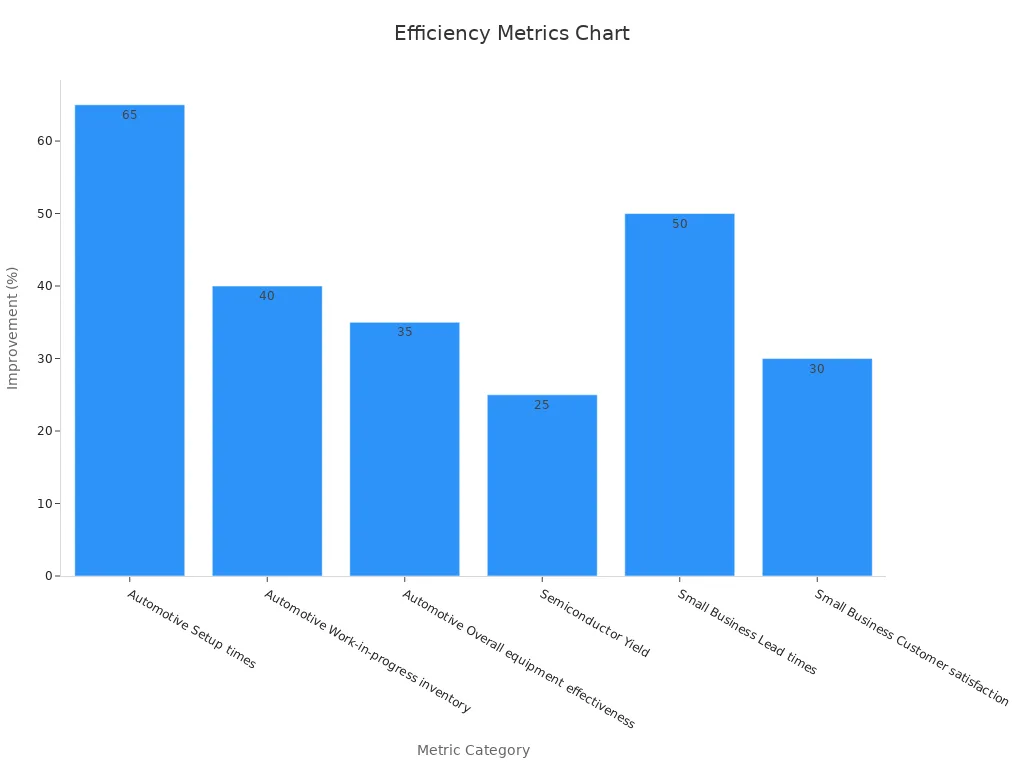

柔軟性もパフォーマンスを向上させます. 車を作ります, 1つのサプライヤーがセットアップ時間を削減します 65%. 彼らはまた、機械を機能させました 35% より良い. チップ製造会社は、セットアップの時間を減らしました 45 に 8 分. この変更により、生産量が増加しました 25%. これらの例は、柔軟性が企業の成功にどのように役立つかを示しています.

目的: 革新的な技術が安全性と生産性を高める方法を探る

新しいテクノロジーは、職場をより安全で生産的にするのに役立ちます. のようなスマートツール IoTセンサー 危険に注意し、事故を止めてください. 例えば, Siemensはセンサーを使用して職場の事故を削減しました 30%. Googleはデータツールを使用して、労働者に感じさせました 40% より安全.

テクノロジーは、人々がより良く働くのにも役立ちます. 調査では、スマートツールを使用している企業が持っていたことがわかりました 20% より幸せで生産的な労働者. 問題を報告するためのアプリは、怪我の時間を削減します 30%. これは、Techが職場をより安全で効率的にする方法を示しています.

| 会社 | 使用される技術 | 結果 |

|---|---|---|

| グーグル | Googleワークスペース | 20% 職場の事故が少ない |

| シーメンス | IoTセンサー | 30% 事故が少ない |

| ハネウェル | AIツール | 彼らが害を引き起こす前に危険を見つけました |

スマートツールを使用すると、作業がより安全で速くなります. 労働者を保護し、企業のパフォーマンスを改善します. これにより、企業は厳しい市場で先に進みます.

ケーススタディ分析: テスラの安全展開哲学

テスラが組み立てラインでトラフィックコーンを使用する方法

テスラは、シンプルなツールがどのようなものかを示しています 交通コーン 安全性を向上させます. コーンを使用してワークステーションを分離し、生産ラインをすばやく変更します. これにより、安全を保ちながら操作が柔軟になります.

- トラフィックコーンを使用することの利点:

- 事故を防ぐために危険を速くマークします.

- 新しいタスクのレイアウトを簡単に調整します.

- 労働者が危険地帯をはっきりと見るのを助けてください.

テスラの柔軟性は、突然の生産の変化に対処するのに役立ちます. 例えば, 車の製造のセットアップ時間が立ち寄りました 65%. 進行中の在庫も倒れました 40%. これらの数字は、基本的なツールと高度なシステムの混合が効率を高める方法を示しています.

チームワーク: 交通コーンおよび安全性のためのその他のツール

テスラは依存していません 交通コーン. コーンとセンサーと障壁を組み合わせて、強力な安全システムを作ります. このチームワークは事故を停止し、生産ラインを迅速に変更できます.

から 2020 に 2024, テスラが報告しました 3,300 オートパイロット安全インシデント. これらの課題は、人間のチェックとスマートツールを混合する安全システムの必要性を強調しています.

コーンをIoTセンサーとペアリングすることにより, テスラは床条件をライブで追跡します. これにより、リスクの高い労働者マシンの相互作用が減少します, より安全で速い仕事をする. 古いツールと新しい技術を組み合わせると、より良い職場が生まれます.

テスラのワークフローで安全兆候が重要な理由

セーフティコーンとサインは、テスラのワークフローの鍵です. 標識は労働者の場所を示しています, 危険ゾーンをマークします, タスクを整理します. コーンと一緒に, 安全コーンとサインは労働者を導き、間違いを防ぎます.

| 業界 | メトリック | 改善 |

|---|---|---|

| 自動車 | セットアップ時間 | そばに落ちた 65% |

| 自動車 | 進行中の在庫 | 下げられます 40% |

| 自動車 | 機器の有効性 | 増加 35% |

テスラのコーンとサインの使用は、労働者を安全に保ち、情報を提供し続けます. このチームワークは事故を削減し、生産を改善します. これらのアイデアを使用すると、職場をより安全で効率的にすることができます.

ケーススタディ分析: Amazon Warehouseの安全展開と効率性が向上します

圧力センサーを備えたよりスマートなトラフィックコーン

Amazonは、組み込みの圧力センサーを備えたトラフィックコーンを使用しています. これらのセンサーは、物事を安全に保つためにリアルタイムで動きをチェックします. コーンが圧力を感じるとき, 監督者にアラートを送信します. これは、危険を早期に発見することで事故を止めるのに役立ちます.

このスマートなアイデアにより、倉庫はより良く機能します. 圧力センサーは、動き回る労働者と材料を追跡します. 彼らは人と機械の間の危険な相互作用を削減しました. これにより、職場を安全に保ち、スムーズに走り続けます. この技術で, Amazonは安全性と生産性を保証します.

圧力センサーは、マネージャーがより良い選択をするのにも役立ちます. 彼らは、労働条件に関するライブアップデートを取得します. これにより、安全性を向上させる計画をすばやく変更できます. また、全体的に倉庫をより効率的にします.

電子標識を備えた自動安全性

Amazonは電子標識を使用して安全性をさらに改善します. これらのサインはセンサーに接続して、危険に関するライブアップデートを提供します. 例えば, センサーがリスクを見つけた場合, サインには警告が表示されます. これにより、労働者は危険を認識し、遠ざけます.

このシステムは、管理者が業務を注意深く監視するのにも役立ちます. シートベルトチェックやドライバーレポートなどのツールにより、役立つ詳細が得られます. これらの機能は安全な習慣を促進し、改善すべき領域を示します. 自動化されたシフト計画により、従業員の疲労も軽減されます, 彼らを警戒させ続ける.

自動化とスマートサインを組み合わせることで, アマゾンは強力な安全システムを構築. これにより事故が減り、効率が向上します. 結果的にはより安全になります, 業界をリードするより良い職場へ.

| 証拠タイプ | 説明 |

|---|---|

| シートベルト監視 | シートベルトの使用状況を確認し、着用していない場合は警告します. |

| 充電完了 | マシンの充電を追跡して遅延を回避します. |

| マシンアイドルレポート | アイドル時間を見つけてマシンの使用率を向上させます. |

| 実行時レポート | 効率を高めるためにアクティブなマシン時間を表示します. |

| ドライバーの行動レポート | ドライバーを追跡してトレーニングのニーズを見つけ、安全性を向上させます. |

| オペレーターの割り当て | 安全のためのスキルに基づいて、労働者を機械に一致させます. |

| シフトの割り当てと管理 | 労働者を警戒させるために時間と休憩を追跡します. |

| 効率の向上 | マシンを完全に使用してコストを節約し、出力を増やします. |

| 強化された安全基準 | クラッシュを防ぎ、問題を早期に修正するための機能を追加します. |

| オペレーターの動作が改善されました | 安全で賢い仕事を奨励するために、ライブフィードバックを提供します. |

これらの高度なツールを使用, Amazonは倉庫を非常に安全で効率的にしています. この技術とアイデアの組み合わせは、仕事を滑らかにし、労働者が保護されています.

OSHA準拠の「プロアクティブ安全エコシステム」ロジック

今日の職場のOSHAコンプライアンスルール

続く OSHAルール 職場をより安全にし、リスクを下げます. これを行うために, パフォーマンスを追跡するセーフティ数に焦点を当てます. これらにはTRIRが含まれます, ダーツレート, およびltifr. 各番号は異なる安全性の詳細を示しています, 怪我が起こる頻度やそれらがどれほど深刻かのように.

| メトリック名 | それが測定するもの |

|---|---|

| 総記録可能なインシデント率 (三つ) | 仕事の怪我や病気をすべてカウントします 100 毎年労働者. |

| 数日先, 制限付き, または転送されます (ダート) レート | 怪我を追跡して、仕事を逃したり、仕事の変更を引き起こします, 事件がどれほど悪いかを示しています. |

| 時間の怪我頻度の頻度 (ltifr) | 怪我を数え、労働時間あたりの勤務時間が失われました, 深刻なケースに焦点を当てています. |

| 重大度 | 合計日は怪我から失われました 100 労働者, インシデントの影響を示します. |

| ニアミスの報告率 | 怪我をしなかった危険を追跡します, 予防を奨励する. |

OSHAが始まってから 1970, 職場での死亡が減少しました 60%. 負傷率も低下しました 10.9 あたり 100 労働者 1972 に 2.7 で 2021. これらの変更は、OSHAルールが職場をより安全にすることを証明しています. 次のような追加の安全基準を使用します ISO 45001 今日のニーズを満たし、強力な安全文化を構築するのに役立ちます.

積極的な安全システムを作成する手順

積極的な安全システムは、発生する前に事故を止めます. 労働者を巻き込むことでこれを行うことができます, 絶えず改善します, スマートツールを使用します. 例えば, 労働者にニアミスを報告するように依頼することは、それによってTrirを下げることができます 44%. AIリスクチェックのようなツールは、リアルタイムで危険を発見することもできます.

| メトリック | 改善 |

|---|---|

| 総記録可能なインシデント率 (三つ) | 44% |

| 数日先, 制限または転送 (ダート) | 48% |

開始する, 明確な安全目標を設定します. データを使用して結果を追跡し、リスクを見つけます. 問題を報告するためにモバイルアプリなどのツールを試してください, それによって失われた時間の怪我を減らします 30%. DMAICのような次の手順 (定義する, 測定, 分析します, 改善する, コントロール) 安全性を改善し続けるのに役立ちます.

積極的な安全性は、小売業のような産業にも役立ちます, 在庫の取り扱いは危険になる可能性があります. 自動化されたシステムは、間違いを減らし、効率を高めることができます. 例えば, 1つの工場では、データを集中化することにより安全追跡が改善されました. これにより、職場はより安全で生産的になりました.

TeslaとAmazonは、シンプルなツールとスマートテクノロジーを混ぜることで作業がより安全で良くなる方法を示しています. 彼らの方法は、柔軟で創造的であることが成功につながることを証明しています.

- 混合戦略を使用している企業は利益を得ます:

- 1つの方法だけを使用するよりも良い結果.

- 10% ちょうどより多くの価値 1.5 年.

- 大きな効率性が向上します (Fスコア: 7.82, P値: 0.00).

コーンなどのツールを使用して、これらのアイデアを試すことができます, センサー, とスマートサイン. これらのツールは安全性を向上させます, 労働者を助けます, そしてあなたのビジネスを成長させてください. 今すぐ新しいアイデアを使用して、先に進みます! 🚀

よくある質問

なぜテスラとアマゾンは安全性と効率がとても上手なのですか?

TeslaとAmazonは、シンプルなツールとスマートテクノロジーをミックスします. 彼らは安全に焦点を当てています, 新しいアイデアを試してみます, 柔軟なままです. これは彼らが彼らの産業をリードするのに役立ちます. それらの方法により、職場はより安全になり、労働者がより生産的になります.

Amazonはどのようにして最大の倉庫を非常にうまく運営していますか?

Amazonは、最大の倉庫でスマートシステムを使用しています. これらには、センサー付きのコーンが含まれます, 電子標識, 安全ツール. これらのシステムは作業をより安全にし、注文をより速く満たすのに役立ちます. これにより、倉庫がスムーズに動作し続けます.

なぜビジネスにとって新しいアイデアを試すのか?

新しいアイデアを試すことは、企業が成長し、改善するのに役立ちます. より良い結果を得るためにツールと方法をテストすることができます. テスラやアマゾンのような企業は、変化と革新にオープンであるために成功しました.

安全ツールは、オンラインショッピングビジネスにどのように役立ちますか?

スマートコーンや標識などの安全ツールは、倉庫の事故を減らします. また、作業をより速く、より整理します. これにより、企業は顧客のニーズを迅速かつ安全に満たすのに役立ちます.

オンラインショッピングで顧客に焦点を当てるのはなぜですか?

顧客に焦点を当てることは、オンラインストアが成功するのに役立ちます. アマゾン, 例えば, 顧客を幸せに保つためにその倉庫がうまく機能することを確認します. これにより販売が改善され、市場で彼らを先取りさせます.