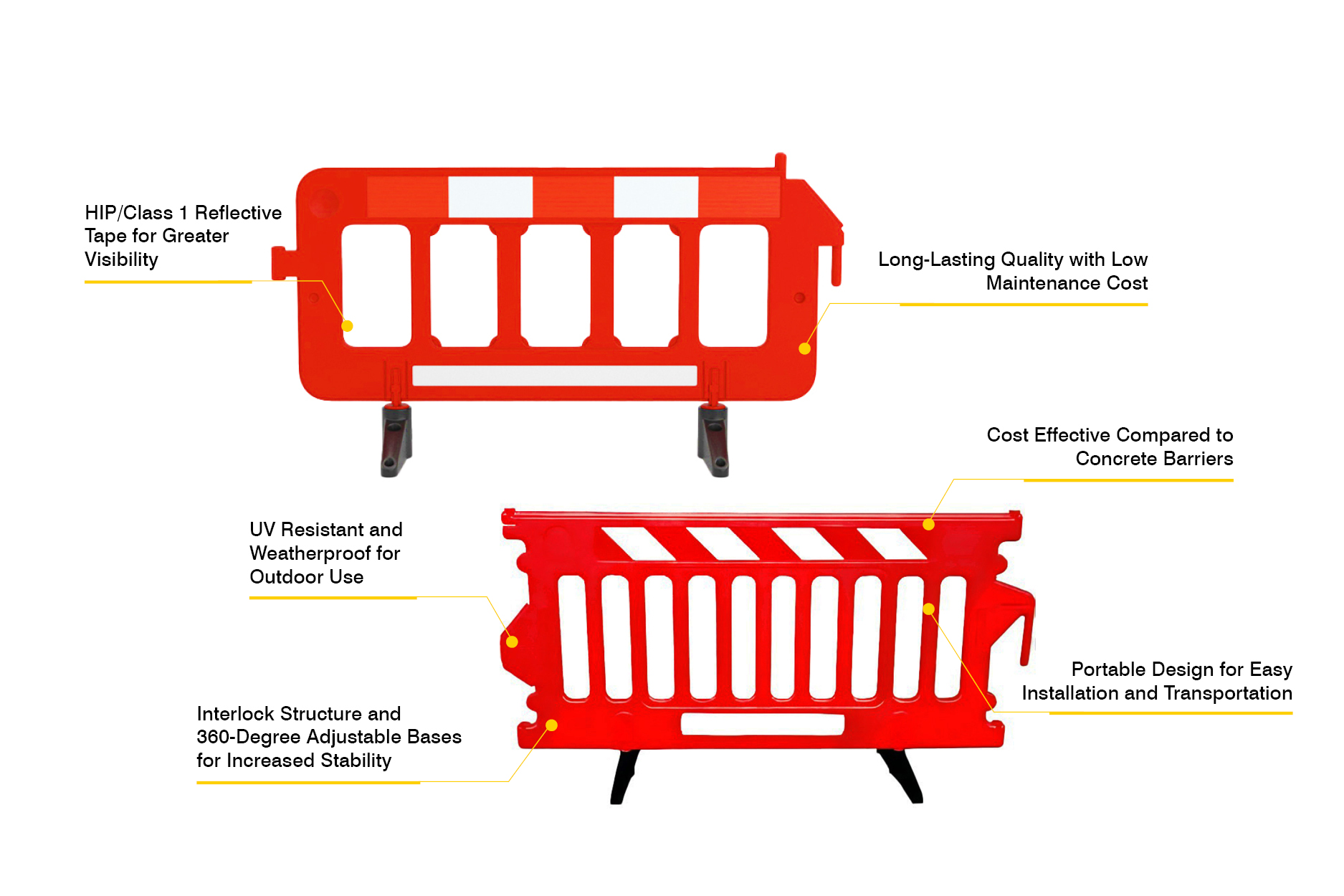

The OPTsigns plastic safety barrier fence is designed with an innovative interlock structure and 360-degree adjustable bases, ensuring superior stability across various terrains. Its lightweight and portable design make it easy to transport and install, providing an ideal solution for quick deployment at construction sites, 駐車場, とイベント. HIP/クラス 1 reflective tape ensures high visibility even in low-light conditions, making it a reliable choice for controlling pedestrian flow and managing road barrier fence setups.

The OPTsigns plastic safety barrier fence is designed with an innovative interlock structure and 360-degree adjustable bases, ensuring superior stability across various terrains. Its lightweight and portable design make it easy to transport and install, providing an ideal solution for quick deployment at construction sites, 駐車場, とイベント. HIP/クラス 1 reflective tape ensures high visibility even in low-light conditions, making it a reliable choice for controlling pedestrian flow and managing road barrier fence setups.

UV-resistant and weatherproof, this barrier safety fence is built to withstand harsh outdoor conditions while maintaining its long-lasting quality. With lower maintenance costs and cost-effective benefits compared to traditional concrete barriers, the plastic barrier fence offers a sustainable and practical solution for businesses seeking reliable safety products from a trusted barrier fence company.

*私たちはあなたの秘密を尊重し、すべての情報が保護されます.

| 長さ | 1950mm, 2000mm |

|---|---|

| 全高 | 1000mm |

| 材料 | PE |

| 反射映画 | なし, 高強度グレード, クラス 1 |

| カスタマイズ | サイズ, ロゴとフィルムグレード |

フェンスバリアを使用するには, first outline the area to be enclosed, like a construction zone or event perimeter. Position fence posts or barrier panels along this boundary, ensuring they’re evenly spaced and securely placed. If using panels, connect each one using built-in connectors or clips. For post-based barriers, attach the fence material to each post with zip ties or clips, 安定性のために緊張し続けます. Ensure the barrier is high and secure enough to prevent access.

プラスチックロードスタッドは、レーン描写装置として機能し、舗装マーカーを上げているように設計されています. プラスチックの道路スタッドは、駐車場で一般的に使用されています, 学校のゾーン, 交通島, 視認性を高め、車両を安全に導くためのガソリンスタンド.

反射的な道路スタッドの視認性の高いリフレクターは、夜間の視界を大幅に向上させます, ドライバーが車線の境界をナビゲートして理解しやすくする. 反射的なロードスタッドは、事故を削減し、全体的な交通管理を改善するのに役立ちます.

はい, OptSigns反射性ロードスタッドは、毎日の交通の摩耗に耐えるように設計された堅牢な材料から構成されています. それらの耐久性のある構造は、さまざまな道路条件で効果的なままであることを保証します.

絶対に! プラスチックの反射型ロードスタッドは屋外で使用するために設計されており、さまざまな気象条件でうまく機能する可能性があります, 雨と雪を含む. それらの反射特性は、環境に関係なく視界を保証します.

プラスチック製の道路スタッドを定期的に検査して、適切に配置され、良好な状態であることを確認することをお勧めします. このメンテナンスは、ドライバーのガイドにおける最適な可視性と有効性を維持するのに役立ちます.

はい, プラスチックの道路スタッドは、昼間と夜間の両方の使用に効果的です. それらの反射設計は、低光条件での視界を向上させます, いつでもドライバーにガイダンスを提供することを保証する.