トラフィックコーン 交通安全において重要な役割を果たします, 建設ゾーンと迂回路を通してドライバーと歩行者を導きます. これらのトラフィックコーンの有効性は、トラフィックコーン構造で使用される材料に大きく依存します. 3つの重要な資料がこの分野を支配しています: PVC, PE, とゴム. それぞれがユニークな利点を提供します. PVC 耐久性と耐候性を提供します, その間 PE 軽量性と耐衝撃性で知られています. ゴム, 一方で, 耐久性と柔軟性が高い. 適切な材料を選択すると、さまざまな条件で寿命と有効性が保証されます.

PVC トラフィックコーン製造における

PVCの特性

耐久性と柔軟性

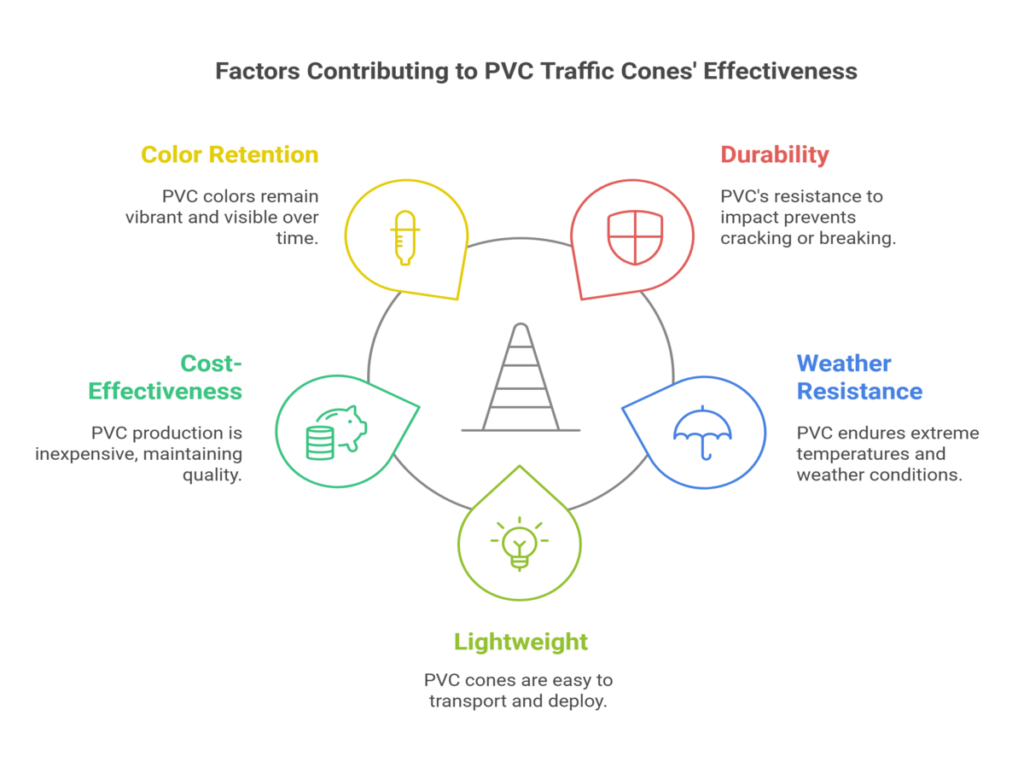

トラフィックコーンの建設に使用される材料を考慮すると, PVC 耐久性と柔軟性に優れています. この材料はさまざまな環境条件に耐えることができます, 屋外での使用に理想的にします. PVC トラフィック コーン として知られています “クラッシュできないトラフィックコーン” 車に衝突すると曲がってしまう可能性があるため, コーンと車の両方へのダメージを軽減します. この柔軟性により、コーンは時間が経っても形状が維持されます。, 長年にわたって信頼できるサービスを提供する.

気象抵抗

PVC 優れた気象抵抗を提供します, それはにとって重要です 交通コーン 風雨にさらされる. これらのコーンは湿気や紫外線に耐性があります, 厳しい日光の下でも明るいオレンジ色を維持します. この機能により、コーンが目に見える状態を維持し、交通誘導に効果的になります。, 気象条件に関係なく.

PVCを使用する利点

費用対効果

重要な利点の 1 つは、 PVC その費用対効果は. PVC トラフィック コーン 手頃な価格で生産できる, 大規模な交通管理プロジェクトで人気の選択肢となっています。. 素材の耐久性により、コーンを頻繁に交換する必要がありません, 長期的にお金を節約します.

デザインの多様性

PVC デザインの多様性を可能にします, メーカーがさまざまなニーズに合わせてさまざまなタイプのトラフィック コーンを作成できるようにする. 暗い場所での視認性を向上させる反射ストリップ付きのコーンが必要か、安定性を高めるためにゴムベース付きのコーンが必要か, PVC これらの要件に対応できます. この適応力により、 PVC 生産に最適な選択肢 さまざまな種類のトラフィックコーン.

トラフィックコーンでの応用

一般的な用途

PVC トラフィック コーン 道路工事区域でよく使用されます, 駐車場, イベント管理. 高い視認性と耐久性により、これらのエリアをドライバーや歩行者を安全に誘導するのに適しています。. プラスチック製のトラフィックコーン’ 軽量なので持ち運びや設置も簡単です。, 実用性を高める.

特定のシナリオ

特定のシナリオでは, 夜間の道路作業や悪天候など, PVC トラフィック コーン 非常に貴重であることがわかります. 反射バンドにより高い視認性を確保, 堅牢な構造は、そのような環境によってもたらされる課題に耐えます。. これらの機能が作成されます PVC に不可欠な材料 トラフィックコーンの種類 要求の厳しいアプリケーション向けに設計.

PE トラフィックコーン製造における

ポリエチレン, 一般的にPEとして知られています, トラフィックコーンの製造に重要な役割を果たします. この材料は世界のプラスチック市場の重要な要素です, さまざまな用途におけるその重要性を強調する, トラフィック管理を含む.

PEの特性

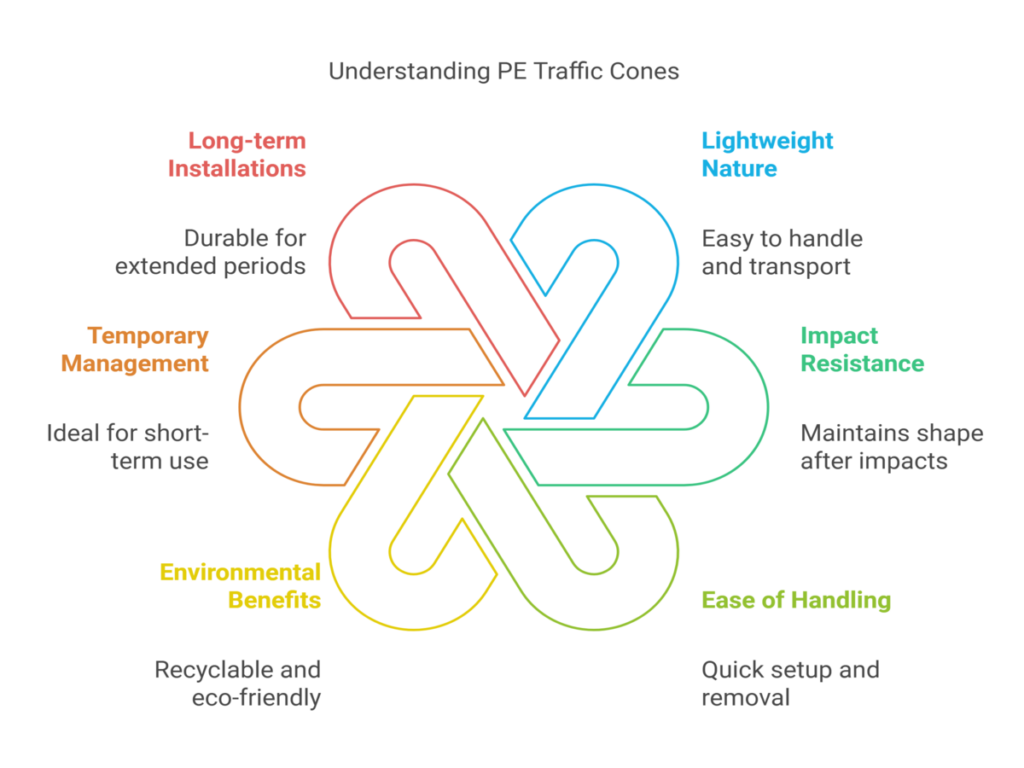

軽量の性質

PEはその軽量性が際立っています. 取り扱いや持ち運びが簡単に行えます PEトラフィックコーン 体重が減ったことにより. この特性により、迅速な展開と削除が必要な状況に最適です。. 通常のプラスチック製トラフィックコーンとは異なります, PE コーンは性能を損なうことなく使いやすさを提供します.

耐衝撃性

PE のもう 1 つの注目すべき特性は、耐衝撃性です。. 車両が誤ってこれらのプラスチック製コーンに衝突した場合, 衝撃を効果的に吸収します, ダメージを最小限に抑える. この機能により、PE トラフィック コーンは繰り返し衝撃を受けた後でも形状と機能を維持します。, それらを交通管理のための信頼できる選択肢にします.

PEを使用する利点

扱いやすさ

軽量設計のため、PE トラフィック コーンの取り扱いは簡単です. 必要に応じてすぐにセットアップしたり削除したりできます, これは、動的な交通状況において特に有益です. この扱いやすさにより、トラフィック管理タスクに必要な時間と労力が削減されます。.

環境上の利点

PE は環境上の利点も提供します. この素材はリサイクル可能です, 持続可能性の取り組みに貢献します. PE トラフィック コーンを選択することにより, 環境に優しい実践をサポートし、廃棄物を削減します, 環境への影響を最小限に抑えるための世界的な取り組みと連携する.

トラフィックコーンでの応用

一時的な交通管理

PE トラフィック コーンは一時的な交通管理シナリオに優れています. 軽量で耐久性があるため、短期のプロジェクトやイベントに最適です。. トラフィック コーンを利用して、明確な誘導と視認性を提供できます。, ドライバーと歩行者の両方の安全性を確保します.

長期設置

長期設置の場合, PE トラフィック コーンは耐久性と復元力を提供します. さまざまな気象条件に耐え、長期間その効果を維持します。. これにより、恒久的または半恒久的なトラフィック管理ソリューションに適しています。, 信頼性が重要な場合.

ゴム トラフィックコーン製造における

ゴムはゴム製トラフィックコーンの製造において極めて重要な役割を果たします, 特定の用途に理想的な選択肢となる独自の特性を提供します. これらの特性と利点を理解すると、特定の種類のトラフィック コーンにゴムが好ましい素材である理由を理解するのに役立ちます。.

ゴムの性質

高い耐久性

耐久性の高さが際立つゴム製. 繰り返しの変形や衝撃吸収に耐える素材です。, トラフィックコーンが常に衝撃を受ける環境に最適です. 他の素材とは異なり, ゴムは頻繁に使用しても完全性を維持します, コーンが長期間にわたって機能し続けることを保証する.

柔軟性とグリップ力

ゴムの柔軟性により、ゴム製トラフィックコーンは破損することなく曲げることができます。, さまざまな状況下でも復元力を発揮. この柔軟性によりグリップ力も向上します, 滑りやすい路面でもゴム製トラフィックコーンが所定の位置に留まるようにします。. ゴム製のコーンを頼りに位置を維持できます, 一貫した指導と安全性を提供する.

ゴムを使用する利点

さまざまな条件下での安定性

ゴム製トラフィックコーンがさまざまな環境で安定性を提供します. 濡れた状態でも乾いた状態でも, これらのコーンは優れたトラクションを提供します, 滑ったり転倒したりするリスクを軽減します. この安定性により、通常のトラフィック コーンでは不十分なヘビーデューティ用途に適しています。.

リサイクルバリティ

ゴムはリサイクル可能です, 環境の持続可能性に貢献する. ゴム製トラフィックコーンを選択することで, あなたは環境に優しい実践をサポートしています, 廃棄物の削減と材料の再利用の促進. このリサイクル可能性は、環境への影響を最小限に抑えるための世界的な取り組みと一致しています。, 交通管理にゴムを責任ある選択をする.

トラフィックコーンでの応用

ヘビーデューティーなトラフィック管理

過酷なトラフィック管理シナリオで, ゴム製トラフィックコーンエクセル. 耐久性と安定性により、車両の通行量が多いエリアや工事現場に最適です。. これらのコーンはそのような環境の要求に耐えられると信頼できます。, 安全性と可視性を確保します.

交通量の多いエリア

ゴム製トラフィックコーンは、交通量の多いエリアで特に効果的です. グリップ力と柔軟性により、所定の位置に留まります, ドライバーと歩行者に確実な誘導を提供します. これらのコーンは、賑やかな場所で秩序と安全を維持するために不可欠です, さまざまなタイプのトラフィック コーンがパフォーマンスを発揮するのに苦労する可能性がある場所.

トラフィックコーンの材質比較

耐久性と長寿

トラフィックコーン建設の材料を選択するとき, 耐久性と寿命が重要な要素. PVC そして ゴム 耐久性が高いことで知られています, 長期使用に適したものにする. PVC の耐候性により、時間が経ってもその色と形状が維持されます。, 過酷な条件でも. ゴム, 柔軟性とグリップ力で, 繰り返しの衝撃や変形に耐えます, 耐久性の高いトラフィックコーンに最適です. PE, 軽量でありながら, 優れた耐衝撃性を提供します, 複数回の攻撃の後でもコーンが機能し続けることを保証する. それぞれの素材が独自の利点を提供します, しかし、ゴムは摩耗や衝撃に対する優れた耐性により、厳しい環境において他のゴムよりも優れた性能を発揮することがよくあります。.

コストに関する考慮事項

トラフィック コーンの建設に使用する材料の選択にはコストが重要な役割を果たします. PVC は、手頃な価格と耐久性により、最もコスト効率の高いオプションとなることがよくあります。. PVCトラフィックコーンを低コストで生産できます, 大規模プロジェクトで人気の選択肢となっています. PE, 軽量な性質により, 交通費の削減によるコストメリットも得られます. ゴム, 最初はより高価です, 耐久性とリサイクル性により長期的な節約が可能. コストを考えると, 初期費用とトラフィック コーンの寿命およびパフォーマンスのバランスをとることが重要です.

環境への影響

トラフィックコーン建設における環境への配慮はますます重要になっています. PE とゴムはリサイクル可能であるため、環境上の利点があります. これらの素材を選ぶことで、, あなたは環境に優しい実践をサポートし、持続可能性への取り組みに貢献します. エヴァ, あまり一般的ではありませんが, 多用途性と環境上の利点も提供します. PVC, 耐久性がありますが, リサイクル可能性の点で課題を抱えている. しかし, リサイクル技術の進歩は、これらの問題の軽減に貢献しています. 素材を選ぶとき, 環境への影響を考慮し、世界的な持続可能性への取り組みと一致するオプションを選択します.

適切な素材の選択 さまざまな種類のトラフィック コーン

トラフィック コーンに適切な材料を選択するには、用途の特定のニーズを理解する必要があります。. それぞれの素材には明確な利点があります, さまざまなタイプのトラフィックコーンに適しています. さまざまな要素を考慮すると、, 選択したものが環境の要求を満たし、安全性が向上していることを確認できます。.

考慮すべき要因

- 耐久性と長寿: トラフィック コーンが目的の環境でどれくらい持続するかを評価する必要があります。. PVCとゴムは耐久性に優れていることで知られています, それらを長期使用に理想的にします. ゴム, 特に, 耐摩耗性と耐衝撃性により、過酷な用途に優れています。.

- 料金: プロジェクトの予算を検討する. 多くの場合、PVC が最もコスト効率の高いオプションとなります, 手頃な価格と耐久性を提供. PE, 軽量な性質により, 輸送コストを削減できる. ゴムの場合は初期費用が高くなりますが、, 長寿命でリサイクル可能であるため、時間の経過とともに節約につながる可能性があります.

- 環境への影響: 選択したものが環境に与える影響を評価する. PEとゴムはリサイクル可能です, 環境に優しい実践をサポートする. PVC はリサイクルに課題をもたらしますが、, テクノロジーの進歩はこれらの問題の解決に役立っています. 持続可能性への取り組みに沿った素材を選択することが重要です.

- 可視性: さまざまな条件下でも高い視認性を維持する素材を確保. PVC の耐候性により、明るい色を保つことができます。, 反射バンドは暗い場所での視認性を高めます。.

- 特定のアプリケーションのニーズ: シナリオが異なれば、異なるタイプのトラフィック コーンが必要になります. 例えば, ゴム製の頑丈なトラフィックコーンは交通量の多いエリアに適しています, 一方、PE コーンは取り扱いが容易なため、一時的なセットアップに最適です。.

アプリケーション固有の推奨事項

- 通常のトラフィックコーン: 一般用途向け, 駐車場やイベント時の交通誘導など, PVC コーンはコスト効率と耐久性のバランスを提供します。. 柔軟性と耐候性により、信頼できる選択肢となります。.

- 頑丈なトラフィックコーン: 工事現場や車両の通行量が多いエリア, ラバーコーンが必要な耐久性と安定性を提供します. グリップ力と柔軟性により、所定の位置に留まります, 一貫した指導を提供する.

- 一時的なインストール: PE コーンは短期プロジェクトに最適です. 軽量なため、迅速な展開と取り外しが可能です。, 動的トラフィック管理に実用的になります.

- 特殊なトラフィック コーンのタイプ: ユニークな用途向け, EVA コーンを検討する. あまり一般的ではありませんが、, EVA は多用途性と環境上の利点を提供します, 従来の素材では不十分な特定のシナリオに適しています。.

これらの要素を慎重に評価し、アプリケーションの特定の要件を理解することで、, トラフィックコーンに最適な素材を選択できます. 最高品質のトラフィック管理ソリューションを実現するには, 耐久性のあるコーンやその他の交通管制装置を含む, 訪問 OptSigns. 当社の製品は、交通管理のニーズの有効性と寿命を高めるように設計されています。.

トラフィックコーン製造の分野で, 適切な材料を選択することが重要です. PVC, PE, およびゴムはそれぞれ、さまざまな種類のトラフィック コーンに独自の利点を提供します。. PVC は、長寿命と高い視認性を保証する耐久性のある PVC 素材を提供します。. PE, 耐衝撃性のあるプラスチックの特性で知られています, 一時的なセットアップに優れています. ゴム, 頑丈な性質を持つ, 交通量の多いエリアに適しています. EVA トラフィック コーンがミックスに多用途性を追加. 適切な素材を選択することで, 最大限の可視性と有効性を確保します, さまざまな環境での安全性を高める. これらのタイプを理解することは、安全コーンのニーズに対して情報に基づいた決定を下すのに役立ちます.