In an age defined by technological innovation and shifting public policy, America’s transportation infrastructure is undergoing rapid transformation. From autonomous vehicles to intelligent traffic systems, the landscape of road safety is evolving fast. Yet amid this push for efficiency and deregulation, one tool remains as relevant as ever—the traffic cone.

This blog explores why, even as federal safety mandates loosen and project timelines accelerate, traffic cones continue to serve as one of the most essential, low-cost safety tools available. From policy analysis to practical use cases, and from accident prevention data to future innovations, we’ll break down why these simple orange markers still matter in 2025 et au-delà.

Introduction: Deregulation Meets Roadside Reality

Long-Term Implications of Policy Changes

Beyond immediate cost savings, these deregulatory policies may have long-term consequences for public safety. As federal agencies reduce hands-on enforcement, more responsibility is pushed to local governments and contractors. This shift is particularly significant for smaller towns or understaffed departments that rely on consistent federal guidance.

The ripple effect touches every part of the transportation ecosystem. From the planning and budgeting of new road projects to on-the-ground safety procedures, the burden of ensuring safe practices increases. And yet, with all this flux, one solution remains constant: the traffic cone—a tool whose impact far exceeds its cost.

How Federal Policies Are Shifting

Au début 2025, NOUS. Transportation Secretary Sean P. Duffy introduced new legislation reducing oversight of vehicle fuel efficiency and infrastructure development approvals. These deregulatory moves were part of a broader effort to boost private sector innovation and reduce costs associated with federal compliance. While such changes may streamline automotive manufacturing and fast-track construction permits, they raise serious concerns about accountability in roadside safety.

The Safety Paradox

The reality on the ground is complex. Deregulation is often seen as a catalyst for economic efficiency, but it also introduces uncertainty in maintaining safety standards—especially in temporary work environments like roadside construction. Without robust oversight, there’s an increased burden on contractors, municipal agencies, and even event organizers to ensure their setups are visibly safe. Ironically, it’s the most basic safety tools—like traffic cones—that remain consistently effective in this evolving landscape. Their importance is magnified, not diminished, in a deregulated era.

Understanding the Role of Traffic Cones in Road Safety

From Visual Cues to Lifesaving Tools

Traffic cones serve as highly visible indicators of danger, directing both vehicle and pedestrian traffic away from hazards. Whether it’s a broken water main in a suburban street or a multi-lane highway repair, cones are often the first sign drivers encounter. Their function extends beyond simple obstruction—they subconsciously prompt reduced speeds and greater driver attention. Cones also play a vital role in reducing liability, as their deployment shows a proactive approach to hazard prevention.

In studies conducted by the Centre national d'information sur la sécurité des zones de travail, areas marked with high-visibility cones saw up to 35% fewer accidents than unmarked or poorly marked zones. This is particularly crucial in urban environments where pedestrian activity intersects with vehicle pathways. Écoles, festivals, défilés, and construction sites all rely on traffic cones to create temporary safety zones that can be adapted within minutes.

Why Cones Still Matter in a Deregulated World

The Value of Simplicity

In times of technological disruption, there’s a tendency to overlook low-tech solutions. But often, it’s these very tools that offer the most consistent performance. Unlike digital signage, cones don’t require maintenance. Unlike mobile apps that alert drivers of road closures, cones deliver immediate visual feedback.

Traffic cones excel in their ability to scale with urgency. When an emergency repair is needed, there’s no time to set up electronic signs. Cones can be placed instantly, giving workers time to establish a more comprehensive safety zone. In fast-moving or chaotic environments, simplicity becomes a strategic advantage.

Speed Without Safety Is a Dangerous Tradeoff

With deregulated approvals, contractors are able to start projects faster, often with minimal notice. This creates time pressure on setup teams, Laissant peu de place pour l'erreur. Traditional safety planning is sometimes seen as a bureaucratic delay, but cutting corners can result in real-world injuries or worse. Traffic cones are one of the few solutions that don’t require planning permission, specialist installation, or significant cost. Ils sont, in effect, the “plug and play” of road safety.

Cones as a First Line of Defense

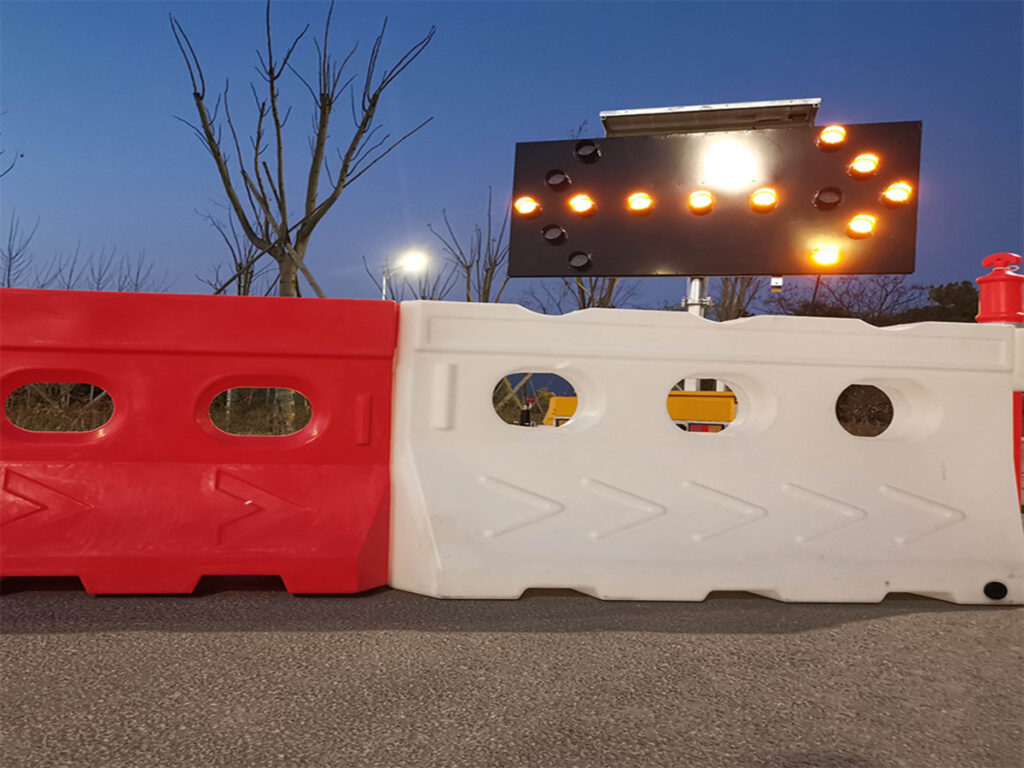

Signalisation intelligente, digital alert systems, and AI-based traffic control are all exciting innovations, but they rely on power, networks, and calibration. Cônes de signalisation, par contre, are immune to outages, unaffected by cybersecurity risks, and require no expertise to deploy. En fait, their sheer simplicity is what makes them such a reliable first line of defense during emergency scenarios. Police officers, EMTs, utility crews, and even civilians can use them to quickly establish control over a developing situation.

Impact du monde réel: When Cones Save Lives

Industry Endorsement and Institutional Adoption

Several organizations—including the American Public Works Association (APWA) et le Conseil national de la sécurité (NSC)—have emphasized the role of visual safety devices in reducing job-site injuries. Municipalities such as Phoenix, Arizona and Charlotte, Caroline du Nord, have implemented cone protocols as part of their Vision Zero safety campaigns. These guidelines require specific cone setups, spacing standards, and reflective ratings for all public utility crews.

In emergency response protocols, cones are considered part of standard operating procedure. Firefighters and EMTs deploy them before traffic is rerouted. Airports use cones for temporary closures on taxiways. In each scenario, the cone is not just a marker—it’s an action that triggers behavioral change.

A Municipal Mistake with Real Consequences

À Springfield, Missouri, a public utilities crew was patching a minor water leak near a quiet intersection. Assuming visibility was sufficient, they skipped cone deployment. Malheureusement, an elderly driver failed to recognize the warning flashers on the service vehicle and clipped a technician who was exiting the truck. The injuries were non-fatal but severe, leading to months of rehabilitation.

The aftermath saw changes in local policy, mandating that all roadside activities lasting more than five minutes require a cone perimeter, regardless of traffic density. This incident illustrates that cones are not just for high-risk areas—they are essential in every public space intervention.

The Statistics Back It Up

Selon le Fhwa, environ 700 fatalities occur annually in work zones. A significant percentage of these could be mitigated with better visibility protocols. Cities that have invested in consistent traffic cone use have reported year-over-year reductions in minor vehicle collisions, particularly in roadwork areas.

Types of Traffic Cones and Their Modern Use

Environmental Resilience and Branding

In addition to function, many organizations now customize their cones for branding or communication. Public utilities may add decals with their logos, while schools might use cones in school colors. Custom labeling such as “Prudence: Gas Leak” ou “Stationnement pour événements” increases situational awareness.

De plus, modern traffic safety cones are made to endure harsh conditions. UV inhibitors preserve color brightness even after long sun exposure. Wind-resistant bases and flexible tops reduce the risk of cones being knocked over or breaking during high-impact contact.

Matching Cone Type to Application

The utility of a traffic cone lies in selecting the correct type. Highway zones require taller cones—often 36 inches—to ensure they’re visible from a distance at high speeds. Urban or pedestrian zones may use shorter, more maneuverable cones. Emergency responders typically keep collapsible cones in their vehicles for quick deployment. These foldable cones are compact, léger, et idéal pour les configurations temporaires.

Features That Matter in 2025

Today’s safety cones have evolved. Reflective collars are now standard on cones intended for low-light environments. Some models are equipped with solar-powered lights that blink or glow continuously at night. Others include weighted rubber bases to prevent tipping in windy conditions or near fast-moving traffic. GPS-enabled cones help fleet managers track equipment and prevent theft or misplacement.

Adapting to New Standards Without Abandoning Safety

MUTCD and FHWA Compliance in 2025

Despite changes in vehicle regulations, le Mutcd has retained its authority over traffic control devices. Contractors must still use cones that comply with these federal guidelines, especially when working on state or federally funded projects. Compliance includes height specifications, minimum reflectivity, and proper color usage (fluorescent orange being the standard).

Certification Is Non-Negotiable

Failing to comply with these standards not only introduces risk but can disqualify contractors from bidding on public contracts. This makes investing in certified equipment essential. Using MUTCD certified traffic cones isn’t just a legal requirement—it’s a best practice that safeguards lives and livelihoods.

Selecting the Right Cone for the Job

Strategic Procurement Considerations

For contractors and city planners, buying traffic cones isn’t just about selecting a shape and color. Factors like storage logistics, deployment speed, replacement cycles, and vendor reliability matter. Choosing a supplier who offers consistent stock availability, rapid shipping, and customization options can make a significant difference in project planning.

Au cours des dernières années, several U.S.-based companies have begun offering subscription-style safety replenishment services. These programs ensure that work crews are always stocked with compliant cones without needing to manually reorder supplies.

Matériels, Visibilité, and Deployment Conditions

Choosing the correct cone starts with the environment. Par exemple, airport maintenance teams require cones that are visible from multiple angles under bright daylight. Construction sites benefit from cones with high durability and reflectivity. Rubber-based cones offer stability in high-wind areas, while PVC cones are more flexible and lightweight.

Understanding these use-case nuances ensures not only safety but also cost-efficiency. The wrong cone may need to be replaced more frequently or fail when most needed. Matching cone material and features to the job at hand should be standard practice in every procurement strategy.

Common Missteps to Avoid

How Small Mistakes Lead to Big Consequences

A common but critical error is neglecting to place cones at a sufficient distance from the hazard. Drivers need time to react, Surtout à des vitesses élevées. En plus, many crews reuse cones well past their usable lifespan. Faded colors and worn reflective strips significantly reduce their effectiveness.

Another pitfall is underestimating pedestrian risk. Cones aren’t just for roads—they’re essential at events, near open utility vaults, and in areas with high foot traffic. Proper training and checklists can go a long way in ensuring correct deployment.

Conclusion: Simple Tools for Complex Times

Reinforcing a Culture of Safety

Finalement, the consistent use of cones is about instilling a culture of safety. When traffic cones are used proactively—not reactively—they show a commitment to protecting workers, conducteurs, et les piétons. They signal preparedness, soins, and foresight.

Organizations that treat cones as essential gear—not just accessories—tend to experience fewer incidents and enjoy higher confidence from their teams and communities. When people see cones, they don’t just see plastic—they see protection.

The Timeless Relevance of Traffic Cones

Even as vehicles become smarter and infrastructure more connected, traffic cones remain relevant. They bridge the gap between planning and action, between chaos and control. Their presence commands attention and communicates danger or instruction instantly.

Réflexions finales

The simplicity of traffic cones makes them both accessible and effective. But their ubiquity should not lead to complacency. Choosing the right cone, deploying it correctly, and maintaining it regularly can mean the difference between a safe work zone and a tragic one.

Perspectives d'avenir: Where Traffic Cone Technology is Headed

Integrating Smart Technology

While traffic cones are celebrated for their simplicity, innovation is steadily transforming even this humble tool. Companies are now piloting cones embedded with IoT sensors that can relay real-time location data, detect collisions, or send alerts when moved unexpectedly. These features are particularly useful in large-scale projects, enabling site managers to monitor work zones digitally.

As more cities adopt smart infrastructure, these “smart cones” may integrate with broader traffic control systems. Imagine traffic safety cones that communicate with approaching vehicles to reduce speed autonomously or cones that change color based on hazard level. Though still in early development, these advancements could redefine work zone safety in the next decade.

Sustainability in Manufacturing

Another focus area is sustainability. Traditional traffic cones are made from PVC and rubber—materials not easily biodegradable. Manufacturers are now exploring the use of recycled plastics or more durable composites that reduce the need for frequent replacement. Some cities have even introduced buy-back or recycling programs for damaged cones, promoting circular economy principles in public procurement.

With continued innovation and a growing emphasis on environmental responsibility, the traffic cone is poised to remain a mainstay of safety—just a smarter and greener one.

Réflexions finales: One Cone, Countless Roles

Despite the rapid pace of regulatory change and technological disruption, the traffic cone has proven to be a rare constant in road safety. Its reliability, abordabilité, and ease of use make it not just relevant—but essential.

Whether you’re managing a major highway project, directing traffic during an emergency, or setting up a safe pedestrian path at a local school, traffic cones remain a frontline defense against confusion, collisions, and chaos.

In a world where bigger and smarter often gets the spotlight, it’s the simple, visible, and time-tested tools like the traffic cone that quietly keep people safe every single day. The next time you pass a row of traffic safety cones on your commute or walk past one at a construction site, remember: small things can make the biggest difference.

To explore what’s ahead for this essential tool, don’t miss our feature article: “2025 Traffic Cone Industry Outlook: Innovation and Demand Driving the Future.”