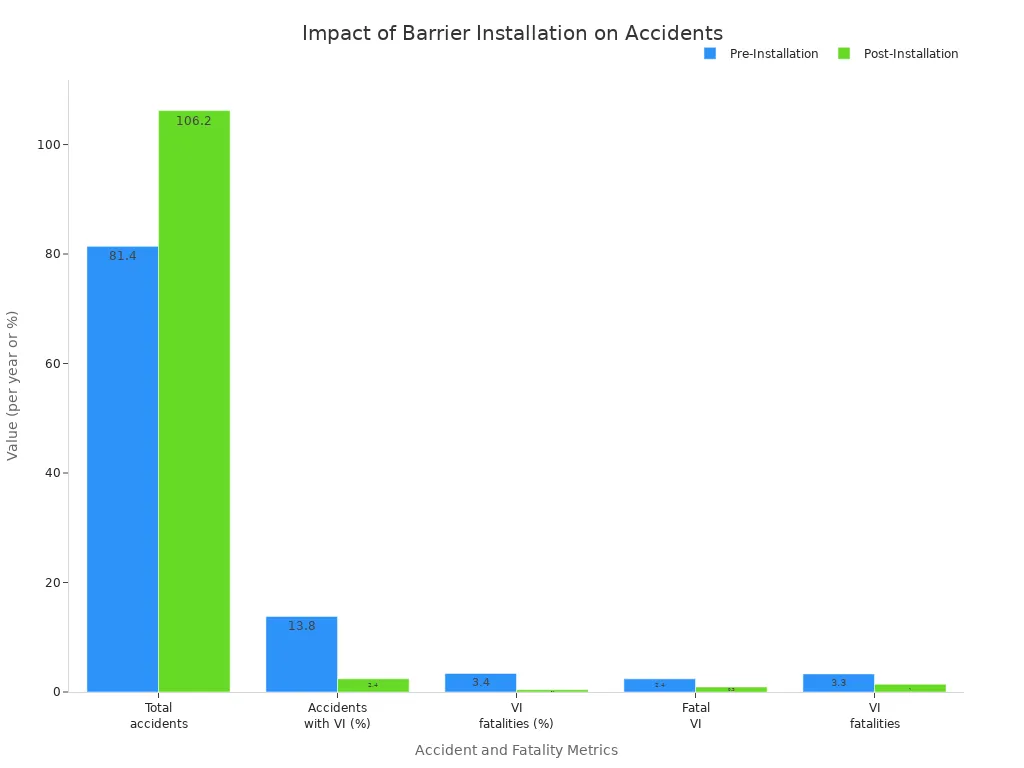

Vous bénéficiez de nombreux avantages avec les barrières remplies d'eau. Ils ont un fort dispositif de sécurité. Cette fonctionnalité absorbe l'énergie d'un accident et réduit les dommages causés par les accidents. Ces barrières sont flexibles. Vous pouvez les installer rapidement dans de nombreux endroits. Utilisez-les sur les chantiers ou dans les zones inondables. Les barricades remplies d'eau permettent d'économiser de l'argent. Ils sont légers, donc les déplacer est facile. Vous pouvez les réutiliser pour d'autres travaux. Le tableau ci-dessous montre comment les barrières réduisent les décès par noyade en voiture:

Découvrez la sélection OPTRAFFIC de barrières à eau, conçu pour offrir une excellente sécurité, flexibilité, et rentabilité pour vos projets. Nos barrières sont faciles à transporter, réutilisable, et construit pour améliorer à la fois la sécurité et la productivité. Découvrez notre gamme dès aujourd'hui pour améliorer la sécurité et l'efficacité de vos chantiers.

Choisir des barrières remplies d'eau

Évaluation des besoins du site

Vous devez savoir ce dont votre site a besoin. Pour la construction de routes, regardez la forme de la route et les éventuelles pentes. Vérifiez les éléments qui pourraient gêner les barrières remplies d'eau.. Si vous souhaitez une protection contre les inondations, voir où se produisent les inondations et quelle est la hauteur de l'eau. Découvrez quelles zones sont les plus à risque. Pensez au sol et s'il y a des bâtiments ou des débris à proximité. Ces choses peuvent affecter votre défense contre les inondations. Il est important de déplacer et de ranger les barrières facilement. Assurez-vous que vous pouvez le faire à la fois pour le contrôle de la circulation et pour la défense contre les inondations..

Conseil: Choisissez des barrières adaptées aux risques sur votre site. Cela contribue à assurer la sécurité de la construction de routes et de la défense contre les inondations..

Facteurs clés à considérer:

- Stabilité du terrain et de la surface

- Risque d’inondation et régimes d’écoulement de l’eau

- Conditions environnementales et débris

- Accès pour le transport et le déploiement

Sélection des types de barrières

Vous devez choisir le barrières remplies d'eau à droite pour ton travail. Décidez si vous en avez besoin pour la construction de routes, contrôle du trafic, ou protection contre les inondations. Pour la protection contre les inondations, choisissez des barrières qui peuvent arrêter les crues des eaux. Ces barrières devraient offrir une bonne protection contre les inondations. Pour la construction de routes, utilisez des barrières qui peuvent encaisser un coup et aider à guider la circulation.

| Type de barrière | Meilleur cas d'utilisation | Force | Adéquation à la défense contre les inondations |

|---|---|---|---|

| Barrières remplies d'eau | Construction de routes, défense contre les inondations | Modéré-élevé | Excellent |

| Paroi moulée en béton | Structures permanentes | Très haut | Bien |

| Mur de palplanches | Défense temporaire contre les inondations | Haut | Modéré |

Pensez aussi à la météo. Certaines barrières fonctionnent mieux dans les endroits froids ou salés. Vérifiez toujours si vos barrières répondent aux règles de sécurité en matière de protection contre les inondations et de construction de routes.. Si vous ne savez pas quoi choisir, demandez à un expert des solutions de défense contre les inondations ou des solutions de protection contre les inondations.

Placement et conformité

Mettre les barrières au bon endroit est très important. Cela est vrai pour la protection contre les inondations et la construction de routes. Installez des barrières remplies d'eau là où elles peuvent bloquer les eaux de crue ou aider à guider la circulation.. Assurez-vous que les gens peuvent voir les barrières. Marquez clairement les endroits dangereux. Utilisez des feuilles réfléchissantes pour le contrôle de la circulation et la protection contre les inondations la nuit.

| Problème de conformité | Comment éviter |

|---|---|

| Mauvais marquage des zones dangereuses | Suivre les règles de sécurité pour un marquage clair |

| Faible visibilité | Utilisez des feuilles réfléchissantes et les directives de l'ADA |

| Faible stabilité | Utiliser des barrières qui répondent aux normes de résistance |

| Inspections manquées | Vérifiez souvent les barrières pour déceler tout dommage ou tout mouvement. |

| Fournisseurs non vérifiés | Achetez auprès de fournisseurs de confiance avec une preuve de conformité |

Vous maintenez votre défense contre les inondations solide et la sécurité de votre construction routière en faisant ces choses. Vérifiez souvent les barrières et placez-les au bon endroit. Cela vous donne une bonne protection et une forte défense contre les inondations. Utilisez toujours des solutions de protection contre les inondations et des solutions de défense contre les inondations fiables pour obtenir les meilleurs résultats.

Installation de barrières remplies d'eau

Il faut bien planifier avant de mettre des barrières. Ceci est important pour la construction de routes ou la protection contre les inondations. Si vous suivez les bonnes étapes, le dispositif de sécurité fonctionnera. Ici, vous apprendrez quoi faire à chaque étape.

Préparation et inspection

Préparez le site et vérifiez d'abord tout votre équipement. Une bonne préparation évite les problèmes plus tard.

- Promenez-vous dans la région. Recherchez les choses qui pourraient gêner. Vérifiez si le sol est bosselé ou présente des trous.

- Mesurer l'espace. Assurez-vous que les points d'entrée et de sortie sont suffisamment larges. Il doit y avoir de la place pour des barrières et une circulation sûre.

- Vérifiez le sol. Il doit être plat et solide. S'il est glissant ou en pente, tu devras peut-être le réparer. Parfois, il faut des tapis antidérapants.

- Regardez chaque barrière. Vérifiez les fissures ou les pièces manquantes. Assurez-vous que la feuille réfléchissante est propre et facile à voir.

- Planifiez comment vous apporterez des barrières sur le site. Décidez où les conserver avant de commencer.

- Parlez à votre équipe. Assurez-vous que tout le monde sait quoi faire et quand.

Conseil: Si tu te prépares bien, tu n'auras pas de retards. Votre projet de construction de route ou de protection contre les inondations se déroulera sans problème.

Positionnement et alignement

Les barrières doivent être au bon endroit pour protéger les personnes et les biens. Un bon alignement aide à guider la circulation et à bloquer les eaux de crue.

- Installer des barrières en bordure de la zone de travaux ou de la zone inondable.

- Assurez-vous que chaque barrière touche la suivante. Des lacunes ou un mauvais alignement affaiblissent la défense.

- Utilisez des barrières avec un cadre en acier si vous devez déplacer des véhicules. Les barrières sans cadre sont bonnes pour le guidage, ne pas arrêter les voitures.

- Connectez chaque barrière avec le matériel que vous obtenez. Ne vous contentez pas de les rapprocher. Des connexions sécurisées arrêtent les mouvements en cas d'accident ou d'inondation.

- Étiquetez clairement chaque barrière. Cela aide les travailleurs et les conducteurs à savoir à quoi sert la barrière..

Note: Suivez toujours les règles locales pour savoir où placer les barrières. Cela maintient votre configuration sûre et légale.

Remplissage et sécurisation

Après avoir mis les barrières en place, remplis-les d'eau. Cela les rend lourds et stables.

- Commencez par souffler de l'air dans la barrière. Cela aligne les calques et facilite le déplacement.

- Remplissez d'eau par l'extrémité face à l'inondation ou à la circulation.. Utilisez un tuyau ou une pompe et allez-y lentement.

- Surveillez les bulles d'air. Laissez l'air s'échapper pour que la barrière soit à plat.

- Remplissez jusqu'au niveau indiqué par le fabricant. Trop d'eau peut le faire basculer. Trop peu d'eau le rend faible.

- Vérifier les fuites. Assurez-vous que tous les bouchons et joints sont bien serrés.

- Verrouillez les barrières en place. Certaines barrières ont des épingles ou des pieds pour une meilleure tenue.

Conseil de sécurité: Vérifiez souvent les niveaux d’eau, surtout s'il fait chaud ou si le travail prend beaucoup de temps. L'eau peut sécher ou geler, ce qui rend les barrières moins stables.

Unités de connexion

Vous devez rejoindre chaque barrière pour former une ligne solide. Ceci est important pour la construction de routes et la protection contre les inondations.

- Utilisez le système de verrouillage ou le matériel du fabricant. Cela maintient les barrières ensemble si elles sont heurtées ou poussées par l'eau..

- Vérifiez chaque connexion deux fois. Les pièces desserrées ou manquantes peuvent créer des espaces et affaiblir la barrière.

- Pour les longues files d'attente, essayez de décaler les articulations. Cela rend la ligne plus forte et arrête le mouvement.

- Après la connexion, marcher sur toute la ligne. Recherchez les points faibles ou les barrières qui ne sont pas droites.

Souviens-toi: De bonnes connexions et un bon niveau d’eau sont très importants. Ils aident à garder les gens, voitures, et la propriété en sécurité pendant la construction de routes et les inondations.

Entretien des barrières remplies d'eau

Prendre soin des barrières remplies d’eau permet de garantir leur bon fonctionnement. Ils contribuent à la sécurité routière et à la protection contre les inondations. Vous devez utiliser de bonnes routines de soins. Cela garantit que les barrières fonctionnent par tous les temps, même les inondations et l'hiver. La vérification et le nettoyage vous aident souvent à détecter rapidement les problèmes. Il maintient les barrières en bon état.

Contrôles quotidiens et hebdomadaires

Vérifiez vos barrières remplies d'eau chaque jour et chaque semaine. Cela vous aide à détecter les problèmes avant qu'ils ne s'aggravent. Voici quelques étapes simples pour les soins quotidiens et hebdomadaires:

- Élaborez un plan pour vérifier souvent toutes les barrières remplies d’eau.

- Choisissez quelqu'un pour examiner chaque obstacle et notez ce qu'il voit.

- Tenir un cahier ou utiliser un ordinateur pour enregistrer les vérifications et les réparations.

- Chercher des fissures, fuites, ou dommages après chaque quart de travail.

- Vérifiez l'eau dans chaque barrière. Ajoutez-en plus s'il est faible, surtout après des journées chaudes ou pluvieuses.

- Surveillez la météo. Si des tempêtes ou des vents forts arrivent, remplir les barrières au bon niveau.

- Vérifier les barrières avant et après les intempéries ou les inondations.

- Remplacez rapidement les barrières brisées pour maintenir votre défense contre les inondations solide.

- Gardez les pièces de rechange et les kits de réparation à proximité pour des solutions rapides.

- Déplacez ou changez les barrières à mesure que votre zone de travail change pour rester en sécurité.

Conseil: Une vérification quotidienne et hebdomadaire vous aide à trouver des fuites, dommage, ou faible niveau d'eau tôt. Cela maintient les barrières prêtes à faire face aux inondations ou aux besoins de sécurité routière..

Nettoyage et qualité de l'eau

Les barrières propres fonctionnent mieux et durent plus longtemps. Saleté, algues, ou les déchets peuvent cacher des fissures ou rendre les barrières difficiles à voir. L'eau propre à l'intérieur arrête la moisissure et les mauvaises odeurs.

- Laver l'extérieur de chaque barrière avec de l'eau et du savon. Enlever la boue et la poussière.

- Rincer les produits chimiques ou le sel, surtout après des inondations ou des travaux routiers en hiver.

- Regarde l'eau à l'intérieur. S'il est sale ou sent, vider et remplir d'eau propre.

- Utilisez un tuyau ou une pompe pour vider et remplir les barrières si nécessaire.

- Vérifiez la présence d'algues à l'intérieur. Nettoyez toute accumulation verte pour garder l’eau bonne.

- Assurez-vous que les bouchons et les joints sont bien serrés après le nettoyage et le remplissage..

Note: Les barrières propres sont plus faciles à vérifier et à réparer. Une bonne eau à l’intérieur aide les barrières à durer plus longtemps et à bien fonctionner lors de longues inondations.

Tâches mensuelles et annuelles

Certains travaux ne doivent pas être effectués souvent mais sont néanmoins importants. Les contrôles mensuels et annuels vous aident à détecter les problèmes que les contrôles quotidiens pourraient manquer.

- Chaque mois, vérifiez si chaque barrière est toujours solide. Chercher la décoloration, fissure, ou plastique fragile.

- Vérifiez tous les joints et joints pour déceler des fuites ou des points faibles.

- Changez toute feuille réfléchissante qui s'est détachée ou décolorée.

- Changez l'eau si elle est là depuis longtemps, surtout après les inondations.

- Testez les serrures et les connexions entre les barrières. Resserrez-les ou réparez-les si nécessaire.

- Une fois par an, vérifiez soigneusement toutes les barrières. Remplacez ceux qui sont gravement endommagés ou qui ne fonctionnent pas bien..

- Avant l'hiver, vérifiez votre plan pour le temps froid. Assurez-vous que les barrières sont prêtes au gel et aux inondations.

Appeler: Des contrôles mensuels et annuels maintiennent les barrières solides et prêtes à faire face aux inondations ou à la sécurité routière.. Ces étapes vous aident à mettre fin aux problèmes soudains et à faire durer les barrières plus longtemps..

Feuille réfléchissante et visibilité

Les barrières doivent être faciles à voir, surtout la nuit ou sous une forte pluie. Les feuilles réfléchissantes aident les conducteurs et les travailleurs à repérer les obstacles de loin.

| Classe de feuilles réfléchissantes ASTM | Type d'adhésif / Caractéristiques | Applications typiques relatives aux barrières remplies d'eau |

|---|---|---|

| Classe 1 | Adhésif sensible à la pression | Signalisation routière permanente sur panneaux métal/aluminium |

| Classe 2 | Adhésif activé par la chaleur | Applications au niveau de l'usine, durabilité extrême aux intempéries |

| Classe 3 | Adhésif amovible | Zones de travail temporaires, détours, signes à court terme |

| Classe 4 | Adhésif sensible à la pression | Appliqué à basse température sans solvants ni chaleur |

| Classe 5 | Envers en tissu, flexible, non adhésif | Produits de signalisation autoportants tels que les panneaux enroulables, cônes, barricades (y compris des barrières remplies d'eau) |

Utiliser la classe 5 feuille réfléchissante à envers en tissu pour barrières remplies d'eau. Ce type convient aux barrières flexibles et est facile à voir en cas de faible luminosité ou d'inondations.. Vérifiez souvent la bâche pour déceler la saleté, peeling, ou décoloration. Essuyez-le avec un chiffon doux et changez-le s'il ne brille plus.

Conseil de sécurité: Bien feuille de réflexion vous aide à respecter les règles de sécurité. Il permet de garder les barrières faciles à voir lors des inondations, la nuit, ou par mauvais temps. C'est l'un des meilleurs moyens de garantir le bon fonctionnement des barrières..

Dépannage et considérations relatives aux inondations

Détection et réparation des fuites

Vous devez vérifier les barrières anti-inondation remplies d'eau pour déceler les fuites., surtout après une inondation ou une utilisation intensive. Les fuites peuvent affaiblir votre protection contre les inondations et mettre votre site en danger. Vous pouvez utiliser plusieurs méthodes pour trouver des fuites:

- Utilisez une caméra infrarouge pour repérer les, zones humides sur la barrière. Cela vous aide à trouver les fuites sans couper ni ouvrir la barrière.

- Écoutez les bruits de fuite avec des microphones au sol. Ces outils vous aident à trouver des fuites cachées en captant le bruit de l'eau qui s'échappe.

- Essayez les tests de pression. Remplissez la barrière et surveillez les baisses de pression. Vous pouvez utiliser une solution savonneuse sur les joints pour voir les bulles là où l'eau s'échappe.

Si vous trouvez une petite fuite, coupez l'alimentation en eau et utilisez une pince ou un film de réparation. Pour les fuites plus importantes, découpez la partie endommagée et installez une nouvelle section avec un connecteur à emboîtement. Après les réparations, remplissez la barrière lentement et vérifiez à nouveau s'il y a des fuites. Cela maintient votre défense contre les inondations solide.

Dommages et remplacement

Les inondations et les impacts peuvent endommager les barrières anti-inondation remplies d'eau. Vous devez vérifier les fissures, trous, ou points faibles après chaque inondation. Si vous constatez des dégâts mineurs, utilisez un kit de patch ou un adhésif résistant aux intempéries. Pour les grandes fissures ou si la barrière ne peut pas retenir l'eau, remplacez-le immédiatement. Gardez toujours des barrières de rechange et des kits de réparation à portée de main.. Cela vous aide à maintenir votre protection contre les inondations en état de marche en cas de risque élevé de crues soudaines..

Météo, Gel, et inondations

Les changements météorologiques peuvent affecter vos barrières anti-inondation remplies d'eau. Par temps froid, vous devez empêcher l'eau de geler à l'intérieur des barrières. Utiliser des solutions antigel ou vider les barrières avant le gel. De fortes pluies ou des inondations peuvent déplacer les barrières si elles ne sont pas pleines ou verrouillées ensemble.. Vérifiez toujours les niveaux d’eau après une inondation. Assurez-vous que les barrières restent en place et que votre défense contre les inondations reste solide.. Par temps venteux, connectez fermement les barrières et vérifiez le mouvement.

Conseil: Planifiez toujours les changements météorologiques. Cela maintient votre protection contre les inondations prête à faire face à toute urgence.

Installation de barrières contre les inondations remplies d'eau

La mise en place de barrières anti-inondation remplies d'eau pour la défense contre les inondations nécessite des mesures prudentes:

- Placez la barrière là où vous avez besoin d'une protection contre les inondations.

- Remplissez les tubes d'eau. Vous pouvez utiliser les eaux de crue si nécessaire.

- Laissez l'air s'échapper par des valves spéciales pendant que vous remplissez. Cela rend la barrière stable et lourde.

- Après le déluge, ouvrir les vannes pour évacuer l'eau et dégonfler la barrière.

- Séchez la barrière et enroulez-la pour la ranger.

- Stockez la barrière dans un endroit sec pour la prochaine inondation.

Vous pouvez également utiliser une barrière temporaire contre les inondations pour une défense rapide contre les inondations.. Suivez toujours les instructions du fabricant pour chaque type de barrière. Cela vous aide à protéger votre site contre les inondations et à garder votre défense contre les inondations prête pour une utilisation future..

Stockage et manutention

Vidange et démontage

Vous devez vider et démonter correctement les barrières remplies d'eau après utilisation.. D'abord, ouvrez les ports ou les bouchons de vidange pour laisser sortir l’eau. De nombreuses barrières sont dotées de trous de drainage spéciaux qui empêchent toute altération et permettent à l'eau de s'écouler rapidement.. Utilisez les ports de remplissage et de vidange pour vider chaque barrière. Certaines barrières ont de grands trous de remplissage avec des capuchons à verrouillage par rotation, donc la vidange est plus rapide. Vous pouvez utiliser des boucles de levage aux extrémités pour vous aider à déplacer la barrière lorsque vous la retirez.. Si vous travaillez dans de l'eau en mouvement, utiliser des outils hydrauliques ou des ancrages pour maintenir la barrière immobile.

| Fonctionnalité | Description |

|---|---|

| Remplir le trou | Grande ouverture avec bouchon tournant pour un remplissage et une vidange faciles. |

| Trous de drainage | Conçu pour une libération rapide de l'eau après utilisation. |

| Boucles de levage | Vous aider à déplacer et contrôler les barrières lors de leur suppression. |

| Fonctionnalités de mobilité | Trous pour transpalette et chariot élévateur pour un mouvement de barrière en toute sécurité. |

Conseil: Recherchez toujours les dommages lors du démontage des barrières. Réparez les petits trous avec de la colle vinylique et du matériel de réparation avant de les ranger.

Stockage sécurisé

En stockant les barrières de la bonne manière, elles seront prêtes pour la prochaine fois.. Suivez ces étapes pour les meilleurs résultats:

- Nettoyez bien chaque barrière. Retirez les couvercles et essuyez tous les côtés.

- Laissez les barrières sécher complètement. Cela arrête la moisissure et maintient le matériau solide.

- Conserver les barrières au frais, lieu sec. Gardez-les à l’abri du soleil et des endroits très chauds ou froids.

- Utilisez des couvercles pour protéger les barrières de la poussière, Rayons UV, et la saleté.

- Ne pas sécher les barrières sur du ciment brut. Cela arrête les taches de sel.

- Rangez les barrières debout si vous le pouvez. Cela les garde plus propres et les protège du soleil.

- Pliez et attachez les barrières réutilisables pour les aider à conserver leur forme.

Note: Un bon stockage fait partie de la prise en charge de vos barrières. Cela les aide à durer plus longtemps et à mieux travailler.

Transport et déménagement

Vous pouvez déplacer facilement les barrières remplies d'eau lorsqu'elles sont vides. Mettez des barrières au nouvel endroit avant de les remplir d'eau. Cela fait gagner du temps et des efforts à votre équipe. Si vous devez à nouveau déplacer les barrières, égouttez-les d'abord. Faites-les glisser ou soulevez-les à l'aide du transpalette intégré ou des trous du chariot élévateur. Ces fonctionnalités vous aident à supprimer rapidement les barrières et à mieux gérer votre site.

- Déplacez toujours les barrières vides pour assurer la sécurité de tous.

- Utiliser des boucles ou des machines de levage pour les barrières lourdes.

- Vérifiez les dégâts après chaque mouvement.

Souviens-toi: Une manipulation sûre et des contrôles réguliers aident vos barrières à rester solides pour chaque tâche.

Vous jouez un rôle clé dans la mise à l’abri des risques d’inondation de votre site. Construire une solide défense contre les inondations, Suivez ces étapes:

- Choisir l'emplacement des barrières en fonction des types d'inondations et des besoins de défense.

- Placez des barrières sur un terrain plat pour une défense stable contre les inondations.

- Remplissez chaque barrière avec la bonne quantité d'eau pour la protection contre les inondations.

- Inspectez souvent les barrières pour repérer les dommages causés par les inondations ou les fuites..

- Entreposer les barrières au sec et couvertes après chaque inondation.

Des inspections régulières et des contrôles de conformité contribuent au bon fonctionnement de votre défense contre les inondations.. Ces contrôles réduisent les risques d’inondation et vous aident à éviter les amendes. Des conseils professionnels vous donnent la meilleure protection contre les inondations pour votre site. La formation vous aide à installer et à entretenir des barrières pour chaque saison d'inondation. Contactez notre équipe pour obtenir une assistance experte et une formation sur les meilleures pratiques de défense contre les inondations..

FAQ

À quelle fréquence devez-vous vérifier les barrières remplies d'eau?

Vérifiez quotidiennement les barrières pour déceler des fuites ou des dommages.. Regardez aussi les niveaux d'eau. Faites un contrôle plus approfondi chaque semaine pour détecter l'usure ou si les barrières ont bougé. Après des tempêtes ou beaucoup d'utilisation, vérifie-les à nouveau. Cela permet de maintenir les barrières sûres et fonctionnelles..

Que faire si une barrière commence à fuir?

Trouvez où se trouve la fuite dès que possible. Utilisez un kit de patch ou de la colle forte pour les petits trous. Si le trou est grand, échanger la barrière contre une nouvelle. Ayez toujours des kits de réparation et des barrières de rechange prêts pour des réparations rapides.

Pouvez-vous utiliser des barrières remplies d'eau par temps glacial?

Oui, tu peux les utiliser quand il fait froid. Mettre de l'antigel dans l'eau ou vider les barrières avant qu'elle ne gèle. Cela empêche la glace de briser la barrière et maintient tout en sécurité..

Comment nettoyer les barrières remplies d'eau?

Nettoyer l'extérieur avec de l'eau et du savon. Laver la boue, sel, ou produits chimiques. Si l'eau à l'intérieur est sale ou sent mauvais, videz-le et remplissez-le d'eau propre. Les barrières propres durent plus longtemps et sont plus faciles à voir.

Quel type de feuille réfléchissante fonctionne le mieux pour les barrières remplies d'eau?

Utiliser la classe 5 feuille réfléchissante à envers en tissu.

Ce type adhère bien aux barrières flexibles et reste lumineux sous la pluie ou la nuit. Vérifiez souvent les feuilles et changez-les si elles s'estompent ou se détachent..