Connaître les règles relatives aux supports de panneaux de signalisation est important. Il contribue à assurer la sécurité des personnes et respecte la loi. Les installer correctement permet aux panneaux de durer plus longtemps et de rester solides.. Cela aide également à empêcher les gens de les voler. Des panneaux clairs et sécurisés rendent les routes plus sûres. Ils guident les promeneurs et les conducteurs, les aider à éviter les accidents.

OPTRAFFIC provides durable street sign brackets for sale designed to meet both national and local standards. OPTRAFFIC sign brackets use weather-resistant materials and reliable construction to keep signs visible, sécurisé, and compliant in any environment.

Principaux à retenir

- Follow MUTCD rules to make street signs clear and safe. This prevents legal problems and protects the community.

- Cueiller, rust-free materials like aluminum or steel for brackets. These materials last longer and lower repair costs.

- Check signs often to catch problems early. Fixing issues quickly keeps signs safe and saves money.

Key Regulations for Street Sign Brackets

MUTCD Standards and Practical Compliance

Le Mutcd (Manuel sur les dispositifs de contrôle de la circulation uniformes) sets national rules for installing street sign brackets. These rules keep signage consistent and easy to understand across the country. Par exemple, in pedestrian areas, the MUTCD requires the bottom of the sign to be at least 7 pieds (2.1 mètres) above ground, et 5 pieds (1.5 mètres) in rural or low-traffic zones.

Brackets must hold signs securely to prevent rotation, sagging, or tampering. A well-designed bracket, comme un top-mount bracket with dual-bolt locking, helps maintain compliance. You can review official MUTCD bracket guidelines in Section 2A.18 here.

Conseil: Check the newest Mutcd updates before starting any project. This keeps your work up-to-date with the latest rules.

Material and Corrosion Protection Guidelines

Street sign brackets must handle tough weather like rain, neige, et la chaleur. Using strong materials helps them last longer. Good materials include aluminum, acier galvanisé, et acier inoxydable. These materials resist rust and damage from weather. Adding coatings like galvanization or powder coating gives extra protection. Use tamper-proof bolts to make the brackets more secure.

Note: Rust-proof brackets last longer and cost less to maintain. This saves both time and money over the years.

Wind Load and Structural Integrity Requirements

In high-wind areas, signs and brackets must withstand strong gusts without bending or detaching. Always calculate expected wind load before choosing a bracket.

Use this simplified formula:

Chargement de vent (lbs) = Effective Projected Area (EPA) × Wind Pressure (psf)

Par exemple:

- A street name sign with 1.5 square feet of EPA

- Dans un 100 mph wind zone → 25 psf wind pressure

- Total force = 37.5 lbs of pressure on the bracket

Add extra weight for ice or snow if the area is subject to freezing weather. Brackets should match or exceed the wind load requirements set by local building codes.

Local and Regional Regulations for Signage

Local rules are important for installing street sign brackets. These rules change depending on your city, county, or state. They may cover things like height, espacement, or visibility. Par exemple, some cities require signs to be at least seven feet high in walking areas. Others may have stricter rules for how close signs can be on one post. Always check with local traffic offices to know the exact rules. Ignoring these rules can lead to fines or unsafe signs.

Rappel: Local rules often work with national ones like the Mutcd. Check both to make sure you follow all the rules.

Types of Street Sign Brackets

Flat Sign Brackets vs. Extruded Sign Brackets

There are two main types of brackets: plat et extrudé. Flat sign brackets work for signs with the same thickness all over. Ils sont légers, Simple à utiliser, and great for regular signs. Extruded brackets are made for thicker, stronger signs. These brackets give more support and handle strong winds or busy areas. Knowing the difference helps you pick the right bracket for your sign.

Not sure which sign bracket fits your sign blade? Lisez notre blog: Plat vs. Panneaux de nom de rue extrudés: Lequel a besoin d'un support plus fort? to compare both options and choose with confidence.

Choosing Brackets for Different Poles and Surfaces

Brackets must match the pole or surface they go on. Pour poteaux ronds, use brackets with a curved shape for a tight fit. Square poles need brackets with flat sides to line up properly. For walls or flat surfaces, use brackets with pre-drilled holes. Picking the right bracket keeps the sign steady and easy to see.

Rappel: Measure the pole’s size or surface area before buying brackets. This saves time and prevents problems during setup.

Specialty Brackets for Unique Signage Applications

Some signs need special brackets for unique uses. Double-sided brackets hold signs that show on both sides. Adjustable brackets let you tilt or turn signs for better angles. Decorative brackets add a nice look for parks or historic places. These special brackets help meet specific needs while following the rules.

Note: Special brackets are made for certain signs. Always check if they fit before using them.

Best Practices for Installing a Street Sign

Processus d'installation étape par étape

Putting up a street sign needs careful planning to keep it safe and strong. Follow these simple steps:

- Pick the Best Spot: Choose a place where drivers and walkers can see it easily. Stay away from areas blocked by trees or buildings. Make sure the spot follows local rules.

- Get the Pole or Surface Ready: Clean off dirt and dust from the pole or surface. This helps the brackets and sign stick well.

- Attach the Brackets: Use the right brackets for the pole or surface. Curved brackets fit round poles, while flat ones work for square poles.

- Fasten the Sign Securely: Line up the sign with the brackets and tighten the bolts. Use special tamper-proof bolts to stop theft or damage.

- Check Stability: Make sure the sign is tight and doesn’t move. Test if it can handle wind and other forces.

- Inspect the Setup: Check the sign’s height and angle. Make sure it’s easy to read from far away and at night.

Conseil: Always check the vertical clearance. Signs lower than 14 pieds 6 inches need warnings for safety.

Tools and Equipment for Safe Installation

Using the right tools makes installing signs easier and safer. Voici ce dont vous aurez besoin:

- Basic Tools: Wrenches, tournevis, and pliers for putting brackets together.

- Special Equipment: Tamper-proof bolts, anti-rotation parts, and locks for extra security.

- Safety Gear: Wear hard hats, gants, and bright vests to stay safe.

- Measuring Tools: Use tape measures and levels to check height and alignment.

- Ladders or Lifts: These help you reach high places safely.

Note: Many installers use aluminum brackets because they last longer in bad weather.

Keeping Signs Safe and Long-Lasting

Follow these tips to keep signs safe and working well for years:

- Choose Strong Materials: Use brackets made of rust-proof materials like aluminum or galvanized steel. These last longer in all kinds of weather.

- Mount Signs Correctly: Attach signs the right way to stop them from falling or moving. Use brackets that fit the pole size, comme 2 ⅜” round post brackets.

- Check Often: Chercher la rouille, boulons lâches, or damage regularly. Replace old brackets to keep signs safe.

- Make Signs Easy to See: Use bright colors and reflective materials for better visibility, surtout la nuit. Bigger signs are safer and easier to read.

- Follow the Rules: Stick to national and local rules for sign height, espacement, et placement. In low-clearance areas, add extra signs to warn drivers.

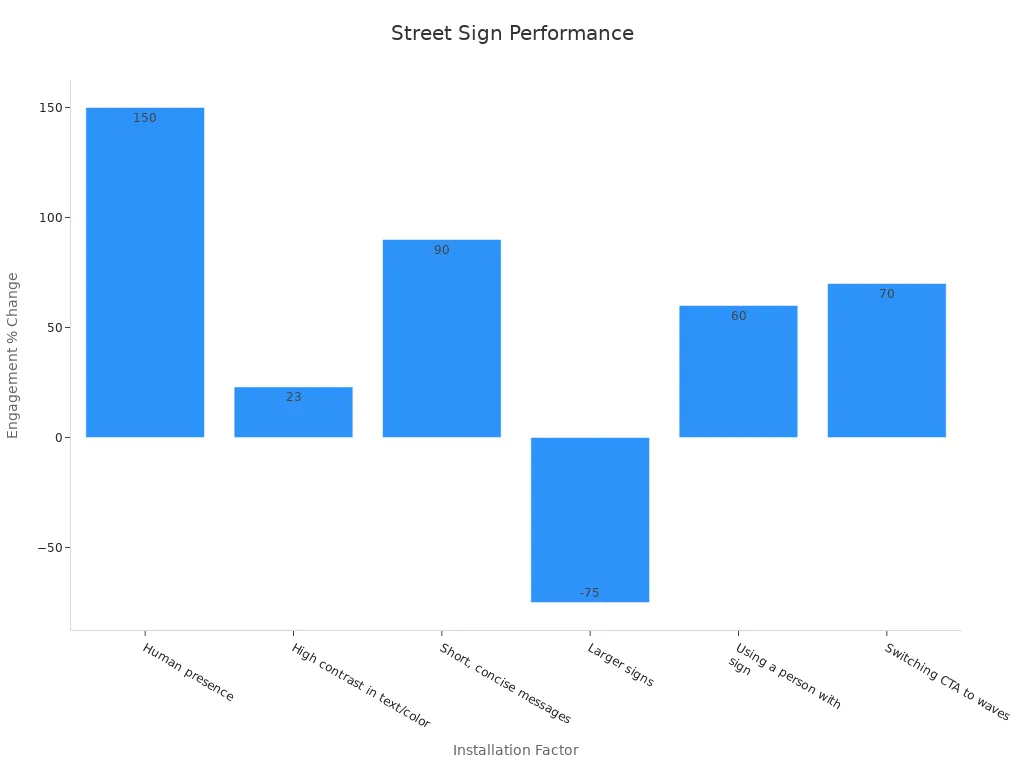

| Facteur | How It Affects Engagement |

|---|---|

| Human presence | Boosts responses by 150% |

| High contrast in text/color | Improves responses by 23% |

| Court, Effacer les messages | 90% plus efficace |

| Signes plus grands | Small signs lower response by 75% |

| Using a person with sign | Raises engagement by 60% |

| Switching CTA to waves | Increases responses by 70% |

En suivant ces étapes, your signs will stay safe and meet the rules. Good planning and setup make signs easier to see and help prevent accidents.

Avoiding Common Mistakes in Street Sign Installation

Mistakes to Avoid During Installation

Avoiding mistakes helps keep street signs safe and useful. Here are some common errors to avoid:

- Wrong Placement: Signs near intersections or behind trees can be hard to see. This makes them less helpful, surtout la nuit.

- Weak Bases: Not digging deep enough or rushing concrete can make poles shaky. A strong base is key for lasting support.

- Signes tordus: If signs aren’t straight, they’re harder to read. Crooked signs can also break easier in wind or crashes.

- Loose Parts: If bolts or brackets aren’t tight, signs may fall. This can be dangerous and cost more to fix later.

Conseil: Always check if signs are straight and secure before finishing.

Fixing Installation Problems

Even with planning, Des problèmes peuvent se produire. Knowing how to fix them quickly saves time and effort.

- Wobbly Signs: If a sign shakes, check the bolts and brackets. Tighten loose parts and make sure the pole is steady.

- Hard to See Signs: If a sign is blocked, look for trees or bad lighting. Move the sign if needed to make it clear.

- Rusty Brackets: Replace rusty parts right away. Use materials like aluminum or galvanized steel to stop rust in the future.

Rappel: Check your signs often to find and fix problems early.

Why Regular Checks and Maintenance Matter

Regular checks keep street signs working well and following rules.

- Rechercher des dégâts: Vérifier les fissures, rouiller, ou boulons lâches. Fix or replace broken parts to keep signs safe.

- Keep Signs Clear: Assurez-vous que rien ne bloque le signe. Trim trees and clean the sign when needed.

- Force de test: Gently shake the pole to see if it moves. Fix the base if it feels unsteady.

Note: Taking care of signs makes them last longer and saves money. Well-kept signs are safer and work better.

Connaissance street sign bracket regulations helps keep signs safe and legal. These rules make signs last longer and protect people on the road. Following them also prevents legal trouble. Use good methods and avoid mistakes to build strong, dependable signs.

Conseil: Check signs often to avoid expensive fixes and keep them working well.

FAQ

What materials work best for street sign brackets?

Aluminum and galvanized steel are great choices. Ils ne rouillent pas et peuvent gérer le mauvais temps, making signs last longer.

How can you stop people from damaging street signs?

Use bolts that can’t be easily removed and strong brackets. Check signs often to find and fix damage quickly.

Can the same brackets be used for monument and pylon signs?

Non, they can’t. Monument and pylon signs need different brackets because they are built and mounted differently.