Les environnements côtiers exigent une résistance à la corrosion pour les bornes. Les bornes en acier inoxydable fonctionnent mieux près de l’eau salée, tandis que les projets intérieurs peuvent utiliser des bornes en béton ou même des cales d'amarrage en fonte. Les bornes en acier à vendre offrent une sécurité pour les deux emplacements. Les cales d'amarrage en acier moulé et les cales d'amarrage en fonte offrent une résistance adaptée aux besoins intensifs. Les cales d'amarrage en fonte résistent également aux chocs et à l'usure.

À la recherche du droit Bollards de la circulation pour votre site? Explorez la gamme complète de solutions de sécurité routière d'OPTRAFFIC et obtenez des conseils d'experts pour votre prochain projet.

Principaux à retenir

- Les zones côtières ont besoin de bornes résistantes à la corrosion, comme des cales d'amarrage en acier inoxydable ou en acier moulé, pour résister à l'eau salée et à l'humidité..

- Les bornes intérieures sont moins exposées à la corrosion due au sel, mais nécessitent néanmoins des revêtements de protection et un entretien régulier pour résister à la pluie., pollution, et les changements de température.

- Les bornes en acier inoxydable offrent une résistance durable et nécessitent peu d'entretien, ce qui les rend idéaux pour les environnements difficiles malgré des coûts initiaux plus élevés.

- Les revêtements protecteurs tels que la galvanisation et le revêtement en poudre prolongent la durée de vie de la borne en bloquant l'humidité et les produits chimiques.

- Une inspection et un nettoyage réguliers aident à prévenir la corrosion et les dommages, garantir que les bornes restent sûres et durables dans le temps.

Corrosion et bornes

Qu'est-ce que la corrosion

La corrosion est un processus naturel qui transforme le métal en une forme plus faible.. Quand l'acier réagit avec l'oxygène et l'humidité, ça forme de la rouille. Cette réaction se produit plus rapidement dans les endroits où l'eau salée ou l'humidité est élevée.. La corrosion peut endommager les objets métalliques au fil du temps, les rendant moins solides et moins sûrs.

Plusieurs facteurs mesurables aident les experts à comprendre comment la corrosion affecte l'acier. Le tableau ci-dessous montre certains de ces facteurs et comment ils sont mesurés:

| Facteur mesurable | Description | Principe de mesure / Méthodologie |

|---|---|---|

| Potentiel de corrosion (Ecorr) | Affiche la différence de potentiel entre l'acier et une électrode de référence; signale un risque de corrosion | Mesure électrochimique de la différence de potentiel; indique une tendance à la corrosion |

| Taux de corrosion | Indique à quelle vitesse la corrosion se produit | Perte de poids sur coupons de corrosion ou résistance de polarisation linéaire (LPR) |

| Résistance à la polarisation | Inversement lié au taux de corrosion; une résistance plus élevée signifie une corrosion plus lente | Méthode LPR mesurant la réponse du courant à de petits changements de tension |

| Bruit électrochimique | Mesure les changements aléatoires de potentiel et de courant | Analyse des fluctuations de potentiel et de courant à l'interface métal-électrolyte |

| Sondes à résistance électrique | Suit la perte de métal en fonction des changements de résistance électrique | Mesure les changements de résistance à mesure que le métal s'amincit; nécessite une compensation de température |

| Corrosion Coupons | Utilise des échantillons de morceaux de métal pour mesurer la perte de poids | Coupons pesés avant et après exposition pour calculer le taux de corrosion |

Potentiel de corrosion (Ecorr) donne une idée rapide du risque de corrosion. Un Ecorr plus positif signifie que la surface de l'acier est mieux protégée. Un décalage négatif montre une plus grande activité de corrosion. Ecorr ne montre pas à quelle vitesse la corrosion se produit, mais cela aide les experts à décider si des tests supplémentaires sont nécessaires.

Effets sur les bornes en acier

La corrosion affaiblit les bornes en acier en rongeant le métal. Au fil du temps, la rouille peut faire perdre aux bornes leur forme et leur résistance. Dans les zones côtières, le sel accélère ce processus. Les emplacements à l’intérieur des terres peuvent connaître une corrosion plus lente, mais la pluie et la pollution peuvent encore causer des dégâts. Quand la corrosion attaque les bornes, ils peuvent ne pas protéger également les personnes ou les biens. Des contrôles réguliers et les bons matériaux contribuent à maintenir les bornes solides et sûres pendant des années.

Facteurs environnementaux

Conditions côtières

Les conditions côtières créent un environnement difficile pour les objets métalliques. L'air chargé de sel de l'océan transporte de minuscules particules de sel qui se déposent sur les surfaces. Lorsque ces particules se mélangent à l'humidité, ils forment une solution corrosive. Une humidité élevée dans les zones côtières accélère ce processus. Le brouillard salin peut atteindre jusqu'à 23 mg/m³, et l'humidité reste souvent entre 70% et 90%. Ces conditions accélèrent la corrosion. Les bâtiments et les structures proches du rivage collectent davantage de sel, surtout s'ils sont plus hauts ou plus proches de l'eau. Les régimes de vent déplacent également le sel plus à l'intérieur des terres. En raison de ces facteurs, les bornes des zones côtières sont confrontées à un risque beaucoup plus élevé de rouille et de dommages. Choisir le bon matériau est important pour garantir la durabilité dans les environnements difficiles.

Conditions intérieures

Les environnements intérieurs n’ont pas autant de sel dans l’air. Les niveaux d'humidité peuvent changer avec les saisons, mais ils restent généralement plus bas qu'à la côte. La pluie et la neige peuvent toujours provoquer une accumulation d'humidité sur les surfaces. La pollution dans les villes peut ajouter des produits chimiques à l'air, ce qui peut également affecter le métal. Changements de température, comme des hivers glacials ou des étés chauds, peut provoquer la dilatation et la contraction du métal. Ce mouvement peut entraîner des fissures ou d'autres dommages au fil du temps. Les bornes situées à l'intérieur des terres sont moins exposées aux risques liés au sel, mais doivent néanmoins être protégées de l'humidité et de la pollution..

Impact sur la durabilité

Les facteurs environnementaux jouent un rôle important dans la durée de vie des bornes. Dans les zones côtières, des niveaux élevés de sel et d’humidité augmentent les taux de corrosion. Cela signifie que les bornes peuvent nécessiter davantage d'entretien ou être remplacées plus tôt.. Les bornes intérieures durent généralement plus longtemps car elles sont confrontées à moins de menaces corrosives. Cependant, pluie, neige, et la pollution peut encore les user. Le choix de matériaux offrant une durabilité et une résistance élevées aide les bornes à relever ces défis. Des revêtements appropriés et des soins réguliers améliorent également leur durée de vie, peu importe où ils sont installés.

Caractéristiques résistantes à la corrosion

Propriétés clés

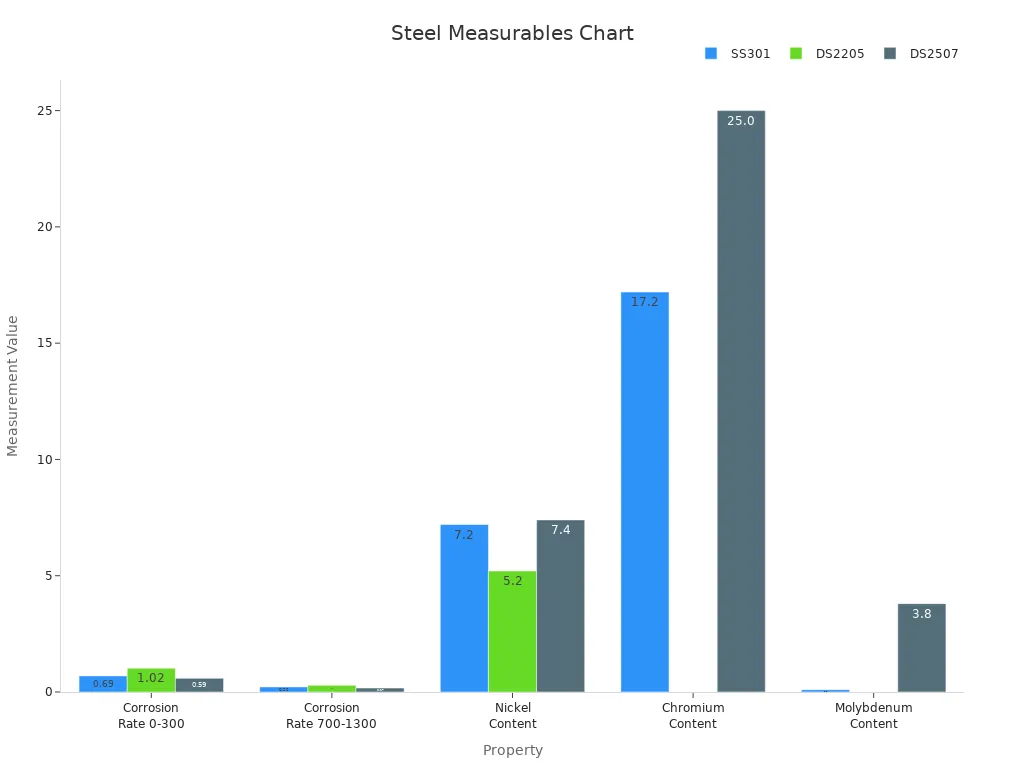

Les bornes en acier à haute résistance à la corrosion durent plus longtemps dans les environnements difficiles. Les ingénieurs mesurent cette propriété en observant la vitesse à laquelle différents aciers se corrodent., leur composition chimique, et dans quelle mesure ils gèrent le stress. Types d'acier inoxydable comme SS301, DS2205, et DS2507 montrent différents taux de corrosion et de perte d'épaisseur. Le tableau ci-dessous montre les performances de ces aciers lors des tests:

| Propriété / Type d'acier | SS301 | DS2205 | DS2507 |

|---|---|---|---|

| Taux de corrosion (mm/an) 0-300 H | 0.69 | 1.02 | 0.59 |

| Taux de corrosion (mm/an) 700-1300 H | 0.22 | 0.29 | 0.17 |

| Teneur en nickel (% en poids) | 7.2 | 5.2 | 7.4 |

| Contenu en chrome (% en poids) | 17.2 | N / A | 25.0 |

| Contenu molybdène (% en poids) | 0.1 | N / A | 3.8 |

| Classement de perte d'épaisseur | Moyen | Le plus élevé | Le plus bas |

| Tests mécaniques | Forte adhérence et durabilité de la couche d’oxyde | ||

| Fissuration par corrosion sous contrainte (CSC) Comportement | Aucune fissure visible; SCC uniquement à des vitesses de déformation lentes supérieures à la limite d'élasticité | ||

| Classement de résistance à la corrosion | DS2507 > SS301 > DS2205 |

Le DS2507 se distingue par son faible taux de corrosion et sa forte couche d'oxyde. Ces caractéristiques aident les bornes à résister à la rouille et aux dommages. Une bonne résistance aux chocs compte également, en particulier dans les zones très fréquentées où des véhicules ou des équipements peuvent heurter les bornes.

Revêtements protecteurs

Les revêtements protecteurs ajoutent une autre couche de défense aux bornes en acier. Les revêtements barrières éloignent l'eau et les produits chimiques du métal. Certains revêtements utilisent des pigments spéciaux, comme des flocons de verre, pour rendre encore plus difficile l'accès de l'humidité à l'acier. Cela aide les bornes à rester solides dans les climats côtiers et intérieurs..

Le tableau ci-dessous compare les revêtements courants et leurs avantages:

| Type de revêtement | Durabilité & Efficacité dans divers climats | Impact environnemental | Exigences de maintenance | Considérations de coûts |

|---|---|---|---|---|

| Galvanisation | Très durable; essentiel pour les conditions côtières et les intempéries | Utilise du zinc | À faible entretien; inspecter les rayures | Coût initial plus élevé, rentable à long terme |

| Revêtement en poudre | Excellente durabilité et résistance aux intempéries | Plus écologique | Des retouches moins fréquentes | Coût modéré; de nombreuses options de couleurs |

| Peinture | Durabilité variable; nécessite un entretien fréquent dans les climats rigoureux | Peut impliquer des produits chimiques | Des retouches régulières sont nécessaires | Coût initial inférieur, coût d'entretien plus élevé |

| Acier inoxydable | Extrêmement durable, entretien minimal | Neutre | Entretien minimal | Coût initial élevé, longue durée de vie |

Conseil: Le choix du bon revêtement dépend du climat local et du degré d'entretien possible.. Les bornes galvanisées et enduites de poudre fonctionnent bien dans la plupart des environnements, tandis que l'acier inoxydable offre la meilleure protection à long terme.

Bornes en acier à vendre: Options matérielles

Bollards en acier inoxydable

Bollards en acier inoxydable se démarquer comme le premier choix pour les environnements difficiles, surtout près de la côte. Grade 316 l'acier inoxydable contient du molybdène, ce qui l'aide à résister à la corrosion causée par l'eau salée et l'humidité. Les fabricants testent ces bornes dans des chambres à brouillard salin pour vérifier leur résistance à la rouille.. Les résultats montrent que les bornes en acier inoxydable conservent leur résistance et leur aspect même après une longue exposition à l'air salin et à la pluie.. Ils ont besoin de peu d'entretien, ce qui permet d'économiser du temps et de l'argent au fil des années. De nombreuses villes utilisent des bornes en acier inoxydable dans les zones riveraines très fréquentées car elles restent brillantes et solides.. Les personnes recherchant des bornes en acier à vendre choisissent souvent l'acier inoxydable pour des projets qui exigent à la fois durabilité et aspect épuré..

Conseil: Les bornes en acier inoxydable fonctionnent mieux dans les endroits très humides, brouillard salin, ou des besoins de nettoyage fréquents.

Acier galvanisé

Bornes en acier galvanisé offrir une solution solide et rentable pour de nombreux projets intérieurs. Ces bornes ont un revêtement de zinc qui protège l'acier en dessous de la rouille. Le prédicteur de durée de vie du revêtement de zinc (ZCLP) utilise des données sur la température, humidité, et de la pollution pour estimer la durée de vie du revêtement. Pour les sites intérieurs, la couche de zinc peut protéger la borne pendant de nombreuses années avant l'apparition de rouille. Le ZCLP aide également les planificateurs de projet à décider quand planifier la première maintenance., en fonction de la quantité de surface présentant des signes d'usure. Les bornes en acier galvanisé à vendre offrent un bon équilibre entre prix et performances, surtout là où l'exposition au sel est faible.

Acier enduit de poudre

Les bornes en acier thermolaqué allient résistance et couleur, finition protectrice. Le revêtement en poudre forme une barrière résistante qui empêche l'eau et les produits chimiques d'entrer.. Cette couche aide à prévenir la rouille et la décoloration, même dans les régions très ensoleillées ou pluvieuses. Des études montrent que les bornes en acier thermolaqué durent plus longtemps que les bornes en béton, qui peut se fissurer ou s'écailler par temps froid. Les bornes en acier à vendre avec revêtement en poudre nécessitent moins d'entretien que les bornes en béton, ce qui en fait un choix judicieux pour les écoles, parcs, et parkings. Le revêtement existe également en plusieurs couleurs, afin que les planificateurs puissent adapter les bornes à leur environnement.

Note: Les bornes en acier thermolaqué offrent une meilleure valeur à long terme que les bornes en béton car elles résistent aux dommages et nécessitent moins d'entretien..

Autres matériaux

Certains projets nécessitent des bornes fabriquées à partir d'alliages d'acier spéciaux ou de matériaux alternatifs. Les aciers alliés au chrome forment une couche protectrice qui bloque la rouille dans les environnements marins et chimiques. D'autres éléments comme le manganèse, molybdène, et le nickel augmentent la ténacité et aident l'acier à supporter la chaleur et le stress. Aciers fortement alliés, tels que les aciers avancés à haute résistance, fonctionne bien dans les endroits à fort trafic ou dans des conditions météorologiques extrêmes. Les aciers micro-alliés et les aciers avancés à haute résistance offrent aux ingénieurs plus d'options pour les projets personnalisés.

- Les aciers alliés au chrome résistent à la corrosion dans les zones marines et extérieures.

- Manganèse, molybdène, nickel, et le vanadium améliorent la ténacité et la résistance à l'usure.

- Les aciers fortement alliés conviennent aux projets qui nécessitent une durabilité accrue.

- Les aciers micro-alliés et les aciers avancés à haute résistance répondent aux besoins particuliers des secteurs de la construction et du transport..

- Ces alliages conservent leur résistance par temps froid ou chaud.

- Les mélanges d'acier personnalisés permettent des solutions uniques dans des environnements difficiles.

Les bornes en béton restent populaires pour certains projets intérieurs car elles résistent à la rouille. Cependant, les bornes en béton peuvent se fissurer ou s'effriter avec le temps, surtout dans les climats froids. Bornes en acier à vendre, surtout ceux avec des revêtements protecteurs, durent souvent plus longtemps et nécessitent moins de réparations que les bornes en béton. Les planificateurs de projet doivent peser les avantages et les inconvénients de chaque matériau avant de faire un choix.

Choix de projets côtiers

Meilleurs matériaux de bornes

Les projets côtiers ont besoin de matériaux capables de résister à des conditions difficiles. Eau salée, vent, et le soleil testent tous la force des bornes. Les bornes en acier inoxydable fonctionnent bien dans ces zones. Ils présentent une forte résistance à la corrosion et conservent leur forme dans le temps. De nombreux ingénieurs choisissent également des cales d'amarrage en acier moulé et des cales d'amarrage en fonte pour les besoins intensifs.. Ces produits sont de la même famille que la quincaillerie marine, ce qui signifie qu'ils sont construits pour des environnements difficiles.

Une comparaison des matériaux courants pour les bornes côtières:

| Matériel | Résistance à la corrosion | Résistance à l'impact | Niveau d'entretien | Utilisation courante |

|---|---|---|---|---|

| Bollards en acier inoxydable | Excellent | Haut | Faible | Bords de l'eau |

| Cales d'amarrage en acier moulé | Très bien | Très haut | Faible | Quais, Piliers |

| Cales d'amarrage en fonte | Bien | Haut | Modéré | Ports, Marinas |

| Acier galvanisé | Modéré | Modéré | Modéré | Utilisation générale |

Conseil: Pour les meilleurs résultats, sélectionner des matériaux testés pour les applications de matériel marin. Ces options durent plus longtemps et nécessitent moins de réparations.

Durabilité en eau salée

L'eau salée fait rouiller le métal plus rapidement. Les bornes près de l'océan sont confrontées à ce problème chaque jour. Les cales d'amarrage en acier moulé et les cales d'amarrage en fonte offrent toutes deux une forte protection contre l'eau salée. Les cales d'amarrage en acier moulé résistent à la flexion et à la rupture lorsque des navires ou des véhicules les heurtent. Les cales d'amarrage en fonte présentent également une résistance élevée aux chocs et peuvent supporter des coups répétés sans perdre leur forme..

Les ingénieurs utilisent souvent à la fois des cales d'amarrage en acier moulé et des cales d'amarrage en fonte dans le même projet. Cette mixité confère au site à la fois solidité et flexibilité. Les bornes en acier inoxydable fonctionnent également bien en eau salée. Ils ne rouillent pas facilement et conservent leur éclat pendant des années. Lors du choix des bornes en acier à vendre, vérifiez toujours si le produit est conçu pour une utilisation en eau salée.

Note: Les cales d'amarrage en acier moulé et les cales d'amarrage en fonte protègent contre la corrosion et les chocs.. Cela en fait un choix judicieux pour les quais et les marinas très fréquentés..

Revêtements UV et réfléchissants

La lumière du soleil peut endommager les bornes au fil du temps. Les rayons UV décolorent la peinture et fragilisent certains matériaux. Les projets côtiers utilisent souvent des revêtements spéciaux pour stopper ces dommages. Les revêtements résistants aux UV gardent les bornes comme neuves. Les revêtements réfléchissants aident les gens à voir les bornes la nuit ou par temps brumeux.

Les cales d'amarrage en fonte et les cales d'amarrage en acier moulé acceptent toutes deux bien ces revêtements.. Les revêtements collent à la surface et ne se décollent pas facilement. Cette couche supplémentaire protège à la fois du soleil et du sel. La résistance aux chocs reste élevée, même après des années de soleil et d'embruns. De nombreux sites côtiers utilisent des revêtements UV et réfléchissants pour respecter les règles de sécurité et garder la zone propre..

Alerte de sécurité: Les revêtements réfléchissants sur les cales d'amarrage en fonte et les cales d'amarrage en acier moulé aident à prévenir les accidents la nuit ou pendant les tempêtes..

Choix de projets intérieurs

Sélection des matériaux

Les projets intérieurs offrent plus de flexibilité lors du choix des bornes. De nombreux planificateurs choisissent les bornes en béton pour leur solidité et leur rentabilité. Les bornes en béton fonctionnent bien dans les parcs, écoles, et parkings. Ils résistent à la rouille et supportent les impacts des véhicules. Les bornes en acier avec revêtement en poudre constituent également une bonne option. Ces bornes offrent une durabilité supplémentaire dans les endroits soumis à des conditions météorologiques changeantes. Certains sites, comme les zones de haute sécurité, exiger des barrières plus fortes. Dans ces cas, les ingénieurs peuvent utiliser des bornes en béton armé ou des bornes en acier avec des fonctionnalités supplémentaires.

Conseil: Adaptez toujours le matériau de la borne au niveau de risque et au type de trafic dans la zone.

Besoins de maintenance

Les bornes situées à l'intérieur des terres nécessitent des contrôles réguliers pour rester en bon état. Les bornes en béton nécessitent moins d'entretien que celles en métal. Les travailleurs doivent rechercher des fissures ou des éclats après un hiver ou une utilisation intensive.. Les bornes en acier avec revêtement doivent être inspectées pour détecter les rayures ou la peinture écaillée.. Des réparations rapides aident à éviter des problèmes plus importants plus tard. Dans les zones à fort trafic, les équipes de maintenance doivent nettoyer les bornes pour éliminer la saleté et le sel de déneigement. Cela garde la zone propre et aide les bornes à durer plus longtemps..

Prévention de la corrosion

La corrosion se produit plus lentement à l’intérieur des terres, mais cela affecte toujours les bornes au fil du temps. Les bornes en béton résistent à la rouille, mais l'eau peut s'infiltrer dans les fissures et causer des dommages. Sceller la surface aide à les protéger. Les bornes en acier bénéficient d'un revêtement en poudre ou d'une galvanisation. Ces revêtements bloquent l'humidité et ralentissent la corrosion. Les planificateurs devraient choisir des bornes avec des finitions de protection éprouvées. Un nettoyage régulier et des réparations rapides empêchent les petits problèmes de se transformer en gros.

Note: Une bonne prévention de la corrosion prolonge la durée de vie des bornes et assure la sécurité à long terme des personnes et des biens.

Coût et valeur

Initial ou à long terme

Lors du choix des bornes, les acheteurs regardent souvent le prix en premier. Les coûts initiaux peuvent varier considérablement selon les matériaux. Les bornes en acier inoxydable coûtent plus cher au début, mais ils nécessitent moins d'entretien au fil du temps. Les bornes en béton ont un prix initial inférieur et fonctionnent bien dans de nombreuses zones intérieures. Cependant, ils peuvent se fissurer et nécessiter des réparations après une utilisation intensive ou des conditions météorologiques difficiles. Les bornes en plastique et en composite sont les plus abordables à acheter et à installer. Ces options conviennent à des usages temporaires ou à faible impact, mais ils ne durent pas aussi longtemps que le métal ou le béton.

Conseil: Pensez à combien vous dépenserez pendant la durée de vie de la borne, pas seulement le premier paiement.

Comparaison des matériaux

Chaque matériau de borne offre des avantages et des coûts différents. Le tableau ci-dessous montre une comparaison simple:

| Matériel | Coût initial | Besoins de maintenance | Durée de vie | Meilleure utilisation |

|---|---|---|---|---|

| Acier inoxydable | Haut | Faible | Très longtemps | Côtier, industriel |

| Béton | Moyen | Moyen | Long | Urbain, trafic élevé |

| Aluminium | Moyen | Faible | Moyen | Décoratif, faible trafic |

| Plastique / polyuréthane | Faible | Très bas | Court-Moyen | Temporaire, à faible impact |

Les bornes en acier inoxydable résistent à la corrosion et nécessitent peu d'entretien, ce qui en fait un choix judicieux pour les projets côtiers. Les bornes en béton offrent résistance et stabilité, mais ils peuvent avoir besoin de réparations s'ils craquent. Les bornes en aluminium sont légères et résistent à la rouille, mais ils ne supportent pas bien les impacts forts. Les bornes en plastique et en polyuréthane sont faciles à installer et à entretenir, mais ils fonctionnent mieux là où les impacts sont rares.

Coût total de possession

Le coût total de possession désigne tout l'argent dépensé pour une borne au cours de sa durée de vie. Cela inclut l'achat, installation, nettoyage, réparer, et le remplacer. Les bornes en acier inoxydable peuvent sembler chères au premier abord, mais leur longue durée de vie et leur faible entretien peuvent permettre d'économiser de l'argent au fil du temps. Les bornes en béton coûtent moins cher à l’achat, mais les réparations peuvent s'additionner si elles craquent. Les bornes en plastique et composites coûtent le moins cher, mais ils devront peut-être être remplacés plus souvent.

Note: Équilibrer budget et performances aide les acheteurs à obtenir le meilleur rapport qualité-prix. Choisir le bon matériau pour l'environnement peut réduire les coûts et augmenter la sécurité pour les années à venir.

Installation et maintenance

Installation côtière

Les zones côtières présentent des défis uniques lors de l'installation. Les travailleurs utilisent souvent de l'acier inoxydable ou de l'acier galvanisé pour ces emplacements. Ils doivent ancrer solidement les bornes pour résister aux vents forts et au sable mouvant.. Les installateurs vérifient le drainage pour empêcher l'eau de s'accumuler autour de la base.. Ils peuvent utiliser des produits d'étanchéité de qualité marine pour empêcher l'eau salée de pénétrer dans les joints.. Les équipes planifient souvent les installations par temps sec pour éviter que l'humidité ne s'accumule à l'intérieur des fondations.. Un alignement et un espacement appropriés aident à maintenir la sécurité et la visibilité le long des passerelles et des quais.

Installation intérieure

Les installations intérieures sont généralement confrontées à moins de risques de corrosion. Les travailleurs peuvent utiliser une plus large gamme de matériaux, y compris le béton ou l'acier peint par poudrage. Ils creusent des fondations stables sous la ligne de gel dans les régions les plus froides. Cette étape empêche le déplacement pendant les cycles de gel-dégel. Les installateurs vérifient les services publics souterrains avant de creuser. Ils utilisent des surfaces planes pour maintenir les bornes verticales et uniformément espacées.. Dans les zones urbaines, les équipes peuvent ajouter des bandes réfléchissantes pour une visibilité supplémentaire.

Nettoyage et entretien

Un entretien régulier permet aux bornes de conserver leur belle apparence et leur bon fonctionnement. Le programme de nettoyage dépend de l'environnement et du type de finition. Par exemple:

- Les finitions enduites de poudre ou galvanisées résistent à la rouille mais nécessitent néanmoins un nettoyage et une repeinture périodiques.

- Les conditions météorologiques extrêmes et l'exposition aux UV nécessitent des revêtements résistants aux intempéries ou aux UV..

- Les équipes de maintenance doivent inspecter, faire le ménage, et retoucher les bornes pour empêcher les petits problèmes de se développer.

- Des contrôles réguliers confirment que les bornes restent intactes, faire le ménage, et bien installé. Un nouveau revêtement ou une peinture peut être nécessaire pour conserver la résistance à la corrosion et la visibilité..

Entretien saisonnier

Chaque saison apporte des besoins d'entretien différents. En hiver, les équipes enlèvent la neige et la glace autour des bornes pour éviter les risques de glissade. Le printemps et l’automne sont de bonnes périodes pour nettoyer en profondeur et vérifier les dommages.. Le soleil d'été peut décolorer la peinture, afin que les équipes puissent appliquer des revêtements de protection UV. Un entretien saisonnier régulier contribue à prolonger la durée de vie de chaque installation.

Les projets côtiers nécessitent une forte résistance à la corrosion. Les cales d'amarrage en fonte protègent du sel et des chocs. Les sites intérieurs peuvent utiliser des cales d'amarrage en fonte pour plus de durabilité. Les cales d'amarrage en fonte assurent également la sécurité à long terme. De nombreux ingénieurs choisissent des cales d'amarrage en fonte pour les zones très fréquentées. Les cales d'amarrage en acier moulé fonctionnent bien dans les environnements marins difficiles. Les planificateurs doivent adapter les bornes à l'environnement. Pour les meilleurs résultats, consulter des experts pour des solutions sur mesure.

Vous ne savez pas quelles bornes de signalisation conviennent le mieux à votre site? Ne manquez pas notre guide pratique: Penser à acheter des bornes de trafic? Demandez à ces 10 Questions d'abord - à lire absolument avant de vous décider.

FAQ

Qu'est-ce qui rend les bornes en acier inoxydable idéales pour les zones côtières?

Les bornes en acier inoxydable résistent à la rouille causée par l'eau salée et l'humidité. Grade 316 l'acier inoxydable contient du molybdène, ce qui ajoute une protection supplémentaire. Ces bornes gardent leur solidité et leur aspect même après des années à proximité de l'océan.

À quelle fréquence les bornes doivent-elles être inspectées pour détecter la corrosion?

Les experts recommandent de vérifier les bornes au moins deux fois par an. Les sites côtiers peuvent nécessiter des inspections plus fréquentes. Des contrôles réguliers permettent de détecter les premiers signes de rouille ou de dommages, garder les bornes sûres et solides.

Les bornes en acier thermolaqué peuvent-elles être utilisées près de l'océan?

Les bornes en acier thermolaqué offrent une bonne protection dans de nombreux environnements. Cependant, l'acier inoxydable fonctionne mieux pour une exposition directe à l'eau salée. Le revêtement en poudre aide, mais le sel peut toujours atteindre l'acier si le revêtement est endommagé.

Quelle est la meilleure façon de nettoyer les bornes dans les environnements côtiers?

Utilisez de l'eau douce et un détergent doux pour éliminer le sel et la saleté.. Rincer abondamment et sécher la surface. Évitez les produits chimiques durs. Un nettoyage régulier aide à prévenir la corrosion et à conserver l'aspect neuf des bornes..

Les bornes intérieures ont-elles besoin de revêtements résistants à la corrosion?

Oui, les bornes intérieures bénéficient de revêtements de protection. Pluie, neige, et la pollution peut encore provoquer de la rouille. Les finitions galvanisées ou thermolaquées contribuent à prolonger la durée de vie des bornes en acier dans les zones non côtières.