Vous protégez votre propriété lorsque vous entretenez des bornes amovibles en acier. L'exposition aux conditions hivernales peut provoquer de la corrosion et des dommages. Si vous négligez l'entretien, les bornes amovibles peuvent geler ou tomber en panne. La neige et le sel peuvent affecter à la fois les bornes robustes et les bornes résistantes aux chocs.. Vous devez inspecter soigneusement les bornes escamotables et les bornes escamotables manuelles.. L'hivernage des bornes amovibles en acier les maintient en état de marche. Les bornes résistantes aux chocs nécessitent une attention particulière pour rester fiables toute la saison.

OPTRAFFIC offre des–acier de qualité bollards conçu pour la durabilité et la fiabilité, Même dans des conditions météorologiques difficiles. Avec une bonne hivernage et un entretien régulier, OPTRAFFIC garantit que vos bornes, qu'elles soient amovibles, résistant aux chocs, ou rétractable : restez fonctionnel et sûr tout au long de l'année, assurer une protection durable de votre propriété.

Principaux à retenir

- Inspectez régulièrement vos bornes amovibles, surtout avant et pendant l'hiver, attraper la rouille, dommage, ou des pièces détachées au début.

- Nettoyer souvent les bornes et les manchons de sol pour enlever la neige, sel, saleté, et débris qui causent des problèmes de corrosion et de gel.

- Protégez les manchons de sol en utilisant des capuchons bien ajustés et des absorbeurs d'humidité pour empêcher l'eau et la glace d'entrer pendant les mois froids..

- Conservez les bornes dans un endroit sec, endroit sécurisé à l'abri de l'humidité et du soleil, et lubrifier les pièces de verrouillage avant le remisage hivernal.

- Effectuer des contrôles avant la saison et après le stockage pour garantir que les bornes fonctionnent correctement et restent fiables toute l'année..

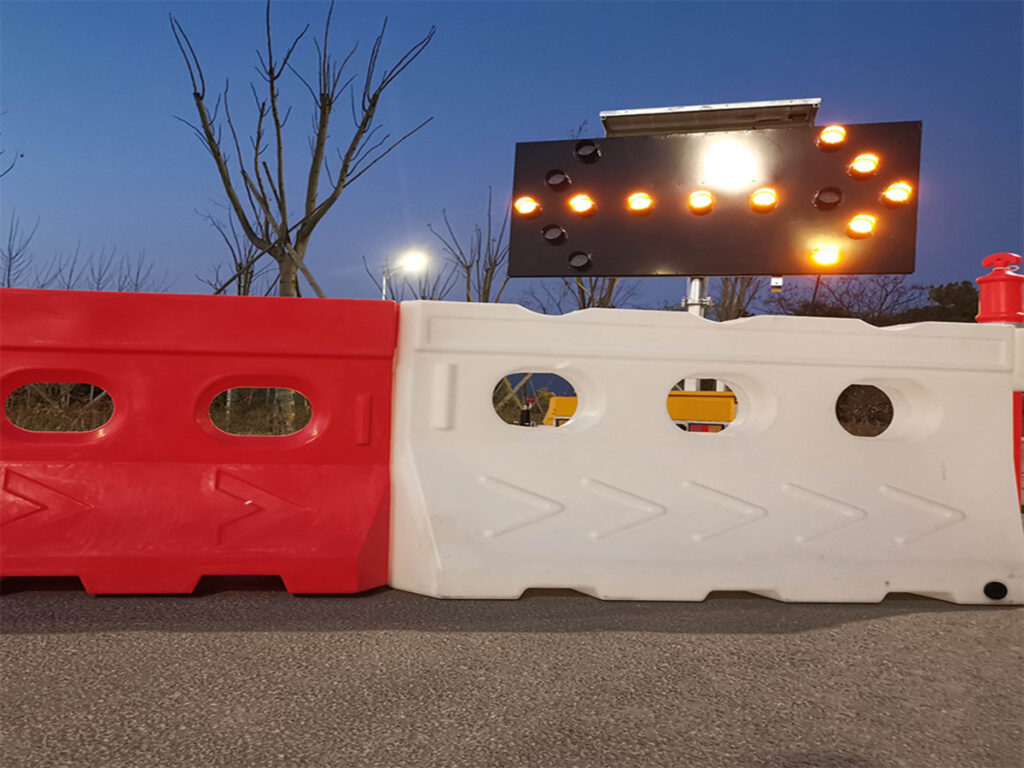

Facteurs de stress environnemental

Neige, Glace, et du sel

L'hiver apporte de nombreux défis pour vos bornes amovibles en acier. La neige s'accumule autour de la base et peut emprisonner l'humidité. La glace se forme lorsque les températures baissent, et cela peut rendre les bornes difficiles à retirer. Le sel utilisé pour faire fondre la glace accélère la corrosion. Vous remarquerez peut-être des taches de rouille ou des piqûres sur la surface. Le sel s'infiltre également dans le manchon de sol, ce qui peut endommager l'intérieur et rendre plus difficile la réinstallation de la borne au printemps.

Conseil: Enlevez toujours la neige et la glace autour de la base de la borne après une tempête.. Cette étape simple aide à prévenir l'accumulation et protège le manchon de terre..

La protection contre le déneigement est importante. Si vous utilisez des charrues ou des pelles, éviter de heurter les bornes. Les impacts peuvent rayer la finition et exposer le métal à l'humidité. Les rayures facilitent le démarrage de la corrosion. Vous devez également vérifier s'il y a des résidus de sel et les rincer si possible..

Cycles de gel-dégel

Gel-dégel les cycles provoquent la dilatation et la contraction de l’eau. L'eau pénètre dans les petites fissures ou interstices autour du manchon de sol.. Quand il gèle, il se dilate et exerce une pression sur le métal. Cela peut entraîner des fissures ou même une flexion. Des cycles répétés fragilisent la borne et le manchon.

Vous devez surveiller les signes de dommages après chaque gel. Recherchez des raccords desserrés ou des changements dans la façon dont la borne s'insère dans le manchon. Si vous détectez les problèmes tôt, vous pouvez éviter des problèmes plus importants plus tard.

Note: Des contrôles réguliers en hiver vous aident à détecter la corrosion et les dommages avant qu'ils ne deviennent graves..

Inspection & Nettoyage

Inspection des bornes en acier amovibles

Vous devez inspecter vos bornes amovibles en acier avant l’hivernage. Une inspection régulière vous aide à détecter rapidement les problèmes et à assurer la sécurité de votre propriété. Suivez ces étapes pour vous assurer que vos bornes restent en parfait état:

- Planifiez des inspections en fonction de votre emplacement, météo, et à quelle fréquence utilisez-vous les bornes.

- Recherchez des signes d'usure, corrosion, puces, ou de la peinture écaillée sur la surface.

- Testez le fonctionnement des bornes escamotables automatiques ou manuelles pour vous assurer de leur bon fonctionnement.

- Nettoyer les bornes pour éliminer les saletés et les polluants pouvant causer des dommages.

- Lubrifiez les pièces mobiles et les mécanismes de verrouillage pour éviter de coller.

- Remplacer les pièces usées, tels que des joints hydrauliques ou des serrures, en suivant les instructions du fabricant.

- Vérifiez le manchon de sol et les fondations pour la stabilité et les signes de déplacement du sol..

- Réparez immédiatement tout dommage pour éviter des problèmes plus importants.

- Tenir des registres de toutes les inspections, réparations, et activités de maintenance.

- Préparez un plan d'urgence au cas où un véhicule heurterait vos bornes résistantes aux chocs ou vos bornes robustes..

Conseil: Une liste de contrôle d'inspection détaillée vous aide à vous souvenir de chaque étape et assure la fiabilité de vos bornes amovibles toute l'année..

Méthodes de nettoyage

Le nettoyage de vos bornes amovibles en acier est un élément clé de l'entretien. Saleté, sel, et la crasse peut s'accumuler rapidement, surtout en hiver. Vous devez utiliser une brosse douce ou un chiffon pour essuyer la surface. Pour les taches tenaces, utiliser du savon doux et de l'eau. Bien rincer pour éliminer tout résidu de savon. Évitez les produits chimiques agressifs qui peuvent endommager la finition.

Si vous avez des bornes résistantes aux chocs ou des bornes robustes, prêtez une attention particulière à la base et aux zones de verrouillage. Ces endroits collectent le plus de débris et d’humidité. Après le nettoyage, sécher complètement les bornes pour empêcher la formation de rouille.

Note: Les bornes propres sont non seulement plus belles, mais durent également plus longtemps et fonctionnent mieux.

Enlèvement des débris

Les débris peuvent causer de gros problèmes aux bornes amovibles. Feuilles, gravier, et les déchets peuvent tomber dans le manchon de terre. Cela rend difficile l'insertion ou le retrait de la borne. Vous devriez vérifier le manchon souvent et éliminer toute accumulation.

Utilisez un aspirateur ou une petite brosse pour enlever les débris du manchon. Pour le matériel collé, une cheville en bois ou un outil en plastique fonctionne bien. N'utilisez jamais d'outils métalliques qui pourraient rayer l'intérieur du manchon.

🧹 Garder le manchon de sol propre aide à prévenir le gel et facilite la réinstallation au printemps.

Étanchéité des manchons & Prévention de l'humidité

Protection du manchon de terre

Vous devez protéger le manchon de sol pour que vos bornes amovibles continuent de fonctionner correctement.. Eau, saleté, et le sel peut pénétrer dans la manche si vous ne la couvrez pas. Ces choses provoquent de la rouille et rendent difficile l'utilisation ultérieure de la borne.. Vous devez toujours vérifier le manchon après avoir retiré la borne. Utilisez un capuchon ou une housse pour bloquer la pluie., neige, et des débris. De nombreux systèmes de bornes sont livrés avec un capuchon bien ajusté. Si votre système n'en possède pas, vous pouvez acheter une housse universelle. Une bonne couverture garde l’intérieur propre et sec.

Conseil: Enlevez toujours les feuilles et les déchets avant de mettre le capuchon. Cette étape aide à arrêter l’accumulation à l’intérieur du manchon.

Prévention de l'humidité dans les manches

L'humidité à l'intérieur du manchon de sol peut geler en hiver. L'eau gelée se dilate et peut fissurer le manchon ou rendre difficile la réinstallation de la borne.. Vous pouvez arrêter cela en gardant la manche au sec. Après avoir retiré la borne, vérifier s'il y a de l'eau au fond. Utilisez une éponge ou une petite pompe pour éliminer toute eau stagnante. Séchez l'intérieur avec un chiffon. Vous pouvez également ajouter une petite quantité de gel de silice ou un sachet absorbant l'humidité.. Ces sachets aident à garder la manche au sec pendant les mois froids.

Techniques de scellement des manchons

Vous pouvez utiliser plusieurs méthodes pour sceller le manchon. Un capuchon en caoutchouc ou en plastique fonctionne bien pour la plupart des manchons. Assurez-vous que le bouchon est bien ajusté afin que l'eau ne puisse pas pénétrer. Certaines personnes utilisent du ruban adhésif résistant aux intempéries sur le pourtour pour une protection supplémentaire. Pour un hivernage longue durée, vous pouvez utiliser un bouchon en mousse à l'intérieur du manchon avant d'ajouter le capuchon. Cette double couche bloque à la fois l'humidité et les débris. Une bonne étanchéité est un élément clé de l’entretien des bornes. Il vous aide à éviter des réparations coûteuses et à garder vos bornes prêtes pour le printemps..

🛡️ Une bonne étanchéité et une bonne prévention de l'humidité protègent votre investissement et facilitent grandement l'hivernage..

Rangement hivernal pour bornes amovibles en acier

Emplacement de stockage

Vous devez choisir un endroit sûr pour ranger vos bornes amovibles en acier pendant l'hiver. Choisissez un endroit sec qui reste au-dessus du point de congélation. L'humidité de l'air peut provoquer de la rouille, évitez donc les sous-sols humides ou les hangars extérieurs avec des fuites. Un débarras verrouillé ou une armoire sécurisée protège vos bornes du vol. La lumière du soleil peut décolorer la peinture et affaiblir les pièces en plastique, donc stocker les bornes à l’abri de la lumière UV directe. Si vous avez des bornes robustes ou des bornes résistantes aux chocs, utilisez des supports ou des étagères rembourrés pour éviter les rayures et les bosses.

Conseil: Étiquetez chaque borne et son capuchon de manchon de sol correspondant. Cela facilite la réinstallation au printemps.

Lubrification des composants de verrouillage

La lubrification est un élément clé de l’hivernage de vos bornes. Avant le stockage, appliquez une huile légère ou un spray de silicone sur toutes les pièces de verrouillage. Cela inclut les broches, charnières, et serrures sur bornes escamotables et bornes escamotables manuelles. La lubrification arrête la rouille et assure le bon fonctionnement des mécanismes. Essuyez l'excès d'huile pour éviter d'attirer la poussière. Consultez le guide du fabricant pour connaître le meilleur lubrifiant à utiliser.

- Nettoyer chaque pièce de verrouillage avant d'ajouter du lubrifiant.

- Déplacez le verrou ou la charnière d'avant en arrière pour répandre l'huile..

- Conservez si possible les pièces lubrifiées dans un sac hermétique.

Un entretien régulier comme celui-ci permet à vos bornes de durer plus longtemps et de mieux fonctionner lorsque vous les réinstallez.

Éviter le gel des manchons de sol

Le gel des manchons de sol peut rendre difficile la réinstallation de vos bornes au printemps. Vous pouvez utiliser plusieurs méthodes pour éviter ce problème. Couvrir le manchon avec un capuchon étanche pour bloquer l'eau et les débris. Ajoutez un sachet absorbant l'humidité à l'intérieur de la manche pour une protection supplémentaire. Certains propriétaires utilisent des matériaux isolants pour garder le sol plus chaud autour de la manche..

Vous pouvez apprendre des autres secteurs confrontés à des cycles de gel-dégel.. Par exemple, en agriculture, les gens utilisent un chiffon résistant au froid, couettes isolantes, ou film de paillage liquide pour protéger le sol du gel. Ces méthodes aident à maintenir la température du sol plus élevée et à réduire les dommages causés par le gel.. En construction, des géotextiles en polyester et des géomembranes composites sont utilisés pour limiter la déformation par le gel. Des études montrent que les géotextiles en polyester réduisent la déformation due au gel à 33.60 mm, tandis que les géomembranes composites atteignent une plus grande chute de température mais permettent une déformation légèrement plus importante à 37.69 mm. Cela signifie que le choix du matériau de protection affecte la manière dont vous pouvez prévenir le soulèvement dû au gel..

| Type de couche de protection | Réduction de la température | Profondeur maximale gelée | Déformation maximale due au gel |

|---|---|---|---|

| Géotextiles en polyester | Réduction modérée | Diminué | 33.60 mm |

| Géomembranes composites | Une plus grande réduction | Diminué davantage | 37.69 mm |

Vous pouvez utiliser des idées similaires pour la protection des manchons de terre. Une couche de mousse isolante ou un tapis résistant aux intempéries sur la zone des manches peut aider. Vérifiez toujours le manchon après une tempête et enlevez toute accumulation de glace ou de neige.. L'hivernage de vos manchons de sol avec ces étapes permet de garder vos bornes prêtes pour une utilisation printanière et de réduire le risque de dommages..

🧊 La prévention du gel des manchons de sol est un élément intelligent de l'entretien des bornes et protège votre investissement..

Inspection programmée & Réinstallation

Inspection de pré-saison

Vous devez toujours commencer par un entretien de pré-saison avant de réinstaller vos bornes amovibles. Cette étape vous aide à repérer tout problème pouvant survenir lors du stockage.. Commencez par vérifier chaque borne pour détecter tout signe de rouille., bosses, ou peinture ébréchée. Examinez les mécanismes de verrouillage et assurez-vous qu'ils se déplacent en douceur. Si vous voyez des dégâts, réparez-le immédiatement pour que vos bornes continuent de fonctionner correctement.

Utilisez cette liste de contrôle pour les soins de pré-saison:

- Inspectez la surface de la borne pour détecter la rouille ou la corrosion..

- Testez les pièces de verrouillage pour un mouvement fluide.

- Vérifiez le manchon de mise à la terre pour déceler des débris ou de l'eau..

- Assurez-vous que le capuchon du manchon est bien ajusté.

- Confirmez que toutes les étiquettes ou marquages sont toujours clairs.

Conseil: Des inspections régulières avant chaque saison vous aident à détecter les petits problèmes avant qu'ils ne deviennent de gros problèmes..

Liste de contrôle après stockage

Après avoir retiré vos bornes du stockage, vous devez suivre une liste de contrôle après stockage. Ce processus garantit que vos bornes sont prêtes à l'emploi et que vous n'avez manqué aucune étape importante. Commencez par nettoyer chaque borne pour éliminer la poussière ou les restes de lubrifiant. Vérifiez à nouveau les composants de verrouillage et appliquez du lubrifiant frais si nécessaire..

Voici une simple liste de contrôle après stockage:

- Nettoyer la surface de la borne et les pièces de verrouillage.

- Inspecter tout nouveau signe d’usure ou de dommage.

- Testez l'ajustement de chaque borne dans son manchon de sol.

- Confirmez que le manchon reste sec et exempt de débris.

- Enregistrez votre inspection et tout entretien effectué.

🛠️ Un bon entretien et des inspections régulières prolongent la durée de vie de vos bornes et assurent la sécurité de votre propriété.

Le stockage saisonnier des bornes et l'entretien régulier maintiennent vos bornes en acier amovibles en parfait état. Vous protégez votre investissement lorsque vous inspectez, faire le ménage, joint, et rangez chaque borne correctement. Ces étapes vous aident à éviter la corrosion, gel, et des réparations coûteuses. Des bornes fiables durent plus longtemps et fonctionnent mieux.

Intégrez les inspections programmées à votre routine de gestion immobilière. Vous verrez moins de problèmes et aurez l’esprit tranquille toute l’année.

FAQ

À quelle fréquence devez-vous inspecter les bornes amovibles en hiver?

Vous devez inspecter vos bornes au moins une fois par mois en hiver. Vérifiez après chaque tempête de neige importante. Des contrôles réguliers vous aident à repérer la rouille, Débris, ou dommages précoces.

Quelle est la meilleure façon de garder les manchons de sol au sec?

Utilisez un capuchon bien ajusté sur chaque manche. Ajoutez un sachet absorbant l'humidité à l'intérieur. Retirez toujours l'eau ou les débris avant de sceller le manchon..

Pouvez-vous utiliser n'importe quel lubrifiant sur les pièces de verrouillage?

Vous devez utiliser une huile légère ou un spray de silicone. Évitez les graisses épaisses. Consultez toujours le guide de votre fabricant pour connaître le meilleur produit.

Pourquoi le sel cause-t-il tant de dégâts aux bornes en acier?

Le sel accélère la rouille et la corrosion. Il détruit les revêtements protecteurs. Vous devez rincer le sel de vos bornes dès que possible.

Que faire si un manchon de sol gèle?

Enlever la glace ou la neige de la zone. Utiliser tiède (pas chaud) de l'eau pour faire fondre la glace à l'intérieur de la manche. Ne forcez jamais la borne dans un manchon gelé.