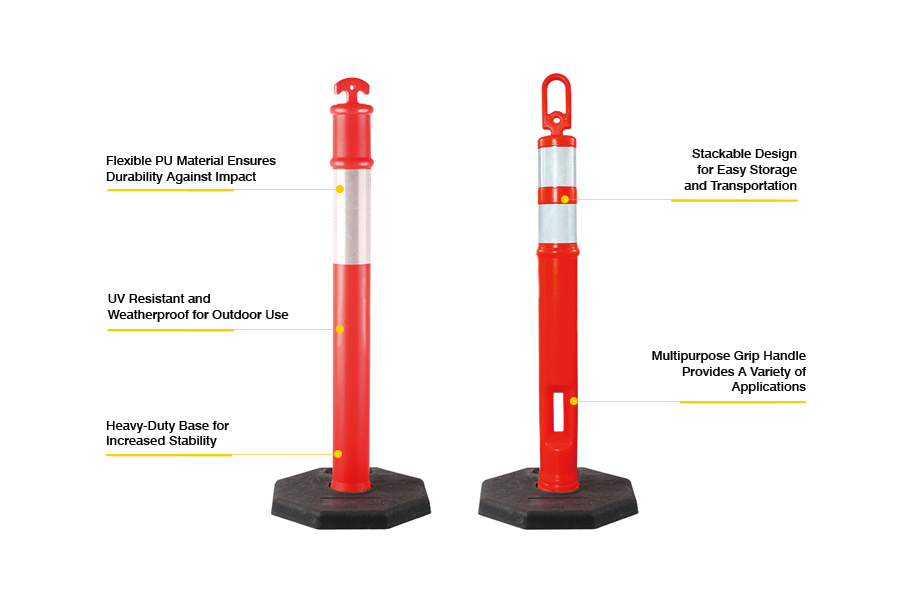

Les bases de bornes OPTsigns T-Top sont fabriquées à partir de haute densité, matière plastique résistante, garantissant des performances durables même dans des environnements extérieurs difficiles. La conception de la base de la borne en caoutchouc robuste améliore la stabilité, faisant de ces bases un excellent choix pour assurer la sécurité des bornes dans diverses applications. La conception réfléchie de la base de la borne comprend des poignées, permettant un transport et un stockage faciles, ce qui les rend pratiques pour les installations temporaires et permanentes. Ces bases sont spécialement conçues pour résister aux conditions météorologiques extrêmes et aux impacts des véhicules, veiller à ce que les bases de poste restent fonctionnelles et fiables.

Les bases de bornes OPTsigns T-Top sont fabriquées à partir de haute densité, matière plastique résistante, garantissant des performances durables même dans des environnements extérieurs difficiles. La conception de la base de la borne en caoutchouc robuste améliore la stabilité, faisant de ces bases un excellent choix pour assurer la sécurité des bornes dans diverses applications. La conception réfléchie de la base de la borne comprend des poignées, permettant un transport et un stockage faciles, ce qui les rend pratiques pour les installations temporaires et permanentes. Ces bases sont spécialement conçues pour résister aux conditions météorologiques extrêmes et aux impacts des véhicules, veiller à ce que les bases de poste restent fonctionnelles et fiables.

En plus, la base en caoutchouc de la borne offre une durabilité supérieure et des caractéristiques de résistance aux intempéries, les rendre idéaux pour une utilisation en plein air. Que vous ayez besoin d'une base en caoutchouc noir à des fins esthétiques ou d'une base de poteau en plastique standard pour des applications fonctionnelles, OPTsigns offre des options polyvalentes. Chaque base est conçue avec des dimensions précises pour garantir un ajustement sûr pour toute configuration de base de poteau de sécurité.. Avec leur construction robuste et leurs fonctionnalités pratiques, Les bases de bornes OPTsigns T-Top se distinguent comme un choix fiable pour améliorer la sécurité et la stabilité dans la gestion et la délimitation du trafic.

*Nous respectons votre confidentialité et toutes les informations sont protégées.

| Taille | 419*419*40mm, 469*469*41mm |

|---|---|

| Poids | 5.5kgs, 6kgs, 7.5kgs, 8kgs |

| Matériel | Plastique |

| Personnaliser | Logo ou marquage |

Le signe octogone sert principalement de signal d'arrêt dans le contrôle du trafic. Sa forme unique est établie par les réglementations de la circulation dans le monde entier pour alerter les conducteurs pour arrêter leurs véhicules pour des raisons de sécurité.

Le panneau de forme octogone indique universellement que les véhicules doivent s'arrêter complet. Le signe de forme d'octagon est un symbole reconnu utilisé pour assurer la sécurité aux intersections et aux zones nécessitant un contrôle du trafic.

La classe 1 Le matériau réfléchissant améliore la visibilité, Rendre le panneau d'arrêt de Go Facile facilement vu dans des conditions de faible luminosité, comme la nuit ou par mauvais temps. Cette fonctionnalité est cruciale pour une gestion et une sécurité efficaces du trafic.

Oui, Le panneau Octagon Road Octagon est conçu pour être léger et portable. Sa poignée télescopique permet un transport et un réglage faciles, rendre pratique pour les contrôleurs de trafic à utiliser dans divers endroits et situations.

Le panneau Octogone Stop Go est fabriqué à partir de poignées en aluminium télescopique durable ou en bois et dispose d'une classe 1 signe réfléchissant. Cette combinaison garantit à la fois la force et la grande visibilité pour une gestion efficace du trafic.

Le panneau d'octogone Stop Go est principalement utilisé par les contrôleurs de circulation, travailleurs de la construction, et le personnel de sécurité pour gérer le débit des véhicules et des piétons dans les zones de travail temporaires et pendant la construction de la route.