Vous utilisez des poteaux de délimitation pour assurer la sécurité des travailleurs. Ces poteaux protègent également les équipements dans les zones de travail très fréquentées. Les messages indiquent où se trouve le danger et aident à guider les voitures et les camions. Cela les rend très importants pour la sécurité et le contrôle de la circulation.. Lors de la sélection des messages, recherchez ceux qui durent longtemps et ne rouillent pas. Le matériel du poste est important. Par exemple, les poteaux en polyuréthane ou en polyuréthane thermoplastique sont très résistants. Voici un tableau qui montre comment certains matériaux se comparent:

| Matériel | Clôture de durabilité |

|---|---|

| Polyéthylène (PE) | Haut |

| Polyuréthane (Puan) | Très haut |

| Acétate de vinyle d'éthylène | Modéré à élevé |

| PU thermoplastique | Très haut |

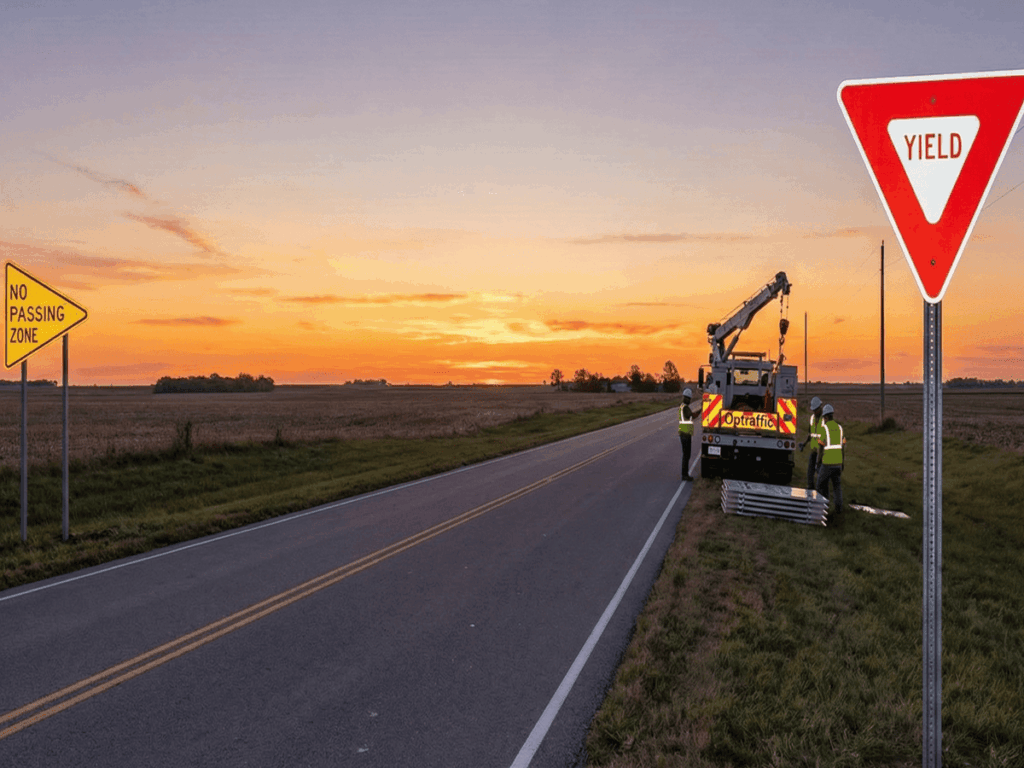

À OPTRAFIC, Nous offrons poteaux de délimitation de haute qualité conçu pour être rapide, contrôle efficace de la circulation dans les situations d'urgence. Notre flexible, poteaux de délimitation durables sont construits pour résister à des conditions difficiles, fournir un déploiement rapide pour garantir des chemins clairs pour les intervenants d'urgence. Facile à installer et très visible, ces postes aident à prévenir d'autres accidents en guidant la circulation en toute sécurité autour des sites d'incidents. Que vous gériez un barrage routier ou créiez un détour temporaire, OPTRAFICLes poteaux de délimitation de offrent des, des solutions durables pour les agences de sécurité publique.

Principaux à retenir

- Choisissez des poteaux de délimitation fabriqués à partir de matériaux solides comme le polyuréthane ou l'acier inoxydable.. Ces matériaux ne rouillent pas facilement. Ils durent plus longtemps dans les endroits difficiles.

- Utilisez des revêtements qui empêchent l’eau de pénétrer et bloquent les rayons UV. Cela protège vos messages de la pluie et du soleil. Cela les aide à rester brillants et forts pendant longtemps.

- Choisissez des conceptions modulaires pour une fixation facile. Vous ne pouvez échanger que les pièces cassées. Cela permet d'économiser du temps et de l'argent. Vos barrières de sécurité fonctionneront toujours bien.

- Vérifiez souvent vos poteaux de délinéation pour déceler des fissures ou une décoloration.. Regardez-les chaque mois. Cela vous aide à trouver des problèmes tôt. Il assure la sécurité des choses et respecte les règles.

- Choisissez des poteaux aux couleurs vives et aux bandes réfléchissantes. Cela les rend plus faciles à voir. Cela réduit les risques d’accidents. Cela vous aide également à respecter les règles de sécurité.

Choisir des poteaux de délinéation durables

Options de matériaux pour la résistance à la corrosion

Vous devez choisir le meilleur matériel pour vos publications de canalisateur. Le matériau que vous choisissez aide votre barrière à rester solide dans les endroits difficiles. Les poteaux de canalisation sont utilisés sur les chantiers de construction et les usines chimiques. On les trouve également dans les zones à fort trafic. Ces endroits ont de la pluie, produits chimiques, et véhicules lourds.

Acier inoxydable, acier galvanisé, et le polyuréthane sont de bons choix. L'acier inoxydable ne rouille pas et n'est pas endommagé par les produits chimiques. L'acier galvanisé a une couche de zinc qui arrête l'humidité et la corrosion. Le polyuréthane est résistant et se plie sans se casser. Cela fonctionne bien pour les publications qui doivent gérer des coups durs.

Les revêtements époxy et les doublures en vinylester protègent également votre barrière. Les résines époxy adhèrent fermement à la surface. Ils bloquent les acides, alcalis, et solvants. Les revêtements époxy éloignent l'eau et les produits chimiques de vos poteaux. Les doublures en vinylester empêchent les mauvais gaz de passer.

Conseil: Appliquer des revêtements époxy sur les poteaux des canaliseurs dans les usines chimiques. Cela aide votre barrière à durer plus longtemps et à rester résistante aux produits chimiques agressifs..

Voici un tableau qui montre comment les matériaux fonctionnent dans des endroits difficiles:

| Matériel | Résistance à la corrosion | Flexibilité | Résistance chimique | Remarques |

|---|---|---|---|---|

| Acier inoxydable | Excellent | Faible | Haut | Idéal pour les zones humides et humides |

| Acier galvanisé | Très bien | Faible | Bien | Le revêtement en zinc ajoute de la protection |

| Polyuréthane | Bien | Haut | Modéré | Flexible et résistant aux chocs |

| Revêtement époxy | Excellent | N / A | Excellent | Utiliser comme couche protectrice |

| Ester vinylique | Bien | N / A | Bien | Utilisation pour les applications de barrière contre les gaz |

Durabilité dans des environnements difficiles

Vos publications de canalisateur doivent survivre dans des moments difficiles. Vous voulez que votre barrière dure de nombreuses années. Les usines chimiques et les zones de construction ont du vent, pluie, produits chimiques, et véhicules. Le bon matériau maintient votre barrière sûre et solide.

Le polyuréthane et le plastique moulé encaissent les coups et se replient. Ils ne se cassent pas et ne se cassent pas facilement. Les poteaux de canalisation robustes peuvent contenir jusqu'à 8 tonnes. Ils restent sur place même lorsque des camions ou des équipements les heurtent.

Les poteaux de canalisation en plastique ne rouillent pas. Ils fonctionnent bien dans les endroits humides ou pluvieux. Des matériaux comme le TPU, HDPE, PVC, et EVA ne se décolorent pas et ne se fissurent pas. Votre barrière reste lumineuse et facile à voir. Ces matériaux fonctionnent également par temps chaud et froid. Ils peuvent supporter la chaleur estivale et le froid hivernal.

Voici un tableau qui montre combien de temps durent les matériaux:

| Source | Durée de vie | Remarques |

|---|---|---|

| Réservoir à noyau en acier | 50-100 années | Nécessite une protection contre la corrosion pour les environnements difficiles |

| Acier Wasatch | 72-75 années | La durée de vie peut diminuer en cas d'exposition chimique extrême |

| Galvanisez-le | Varie | Dépend de la température et de l'humidité |

| Galvanisation universelle | À long terme | Bon pour la planification financière |

Les poteaux de canalisation fabriqués à partir de matériaux solides nécessitent moins de fixations. Vous économisez du temps et de l'argent sur les réparations. Votre barrière assure la sécurité des travailleurs et des équipements. Suivez les étapes d'installation pour vous assurer que vos publications fonctionnent bien. Une bonne installation permet à votre barrière de durer plus longtemps.

Note: Vérifiez toujours les publications de votre canalisateur après les avoir installées. Chercher des fissures, décoloration, ou dégâts. Remplacez rapidement les pièces cassées pour assurer la sécurité de votre site.

Vous utilisez des poteaux de canalisation pour marquer les zones dangereuses et guider les voitures. Ils protègent également les personnes. Le bon matériau vous offre une barrière solide qui dure. Vous obtenez une meilleure durabilité et dépensez moins d’argent au fil du temps.

Caractéristiques de conception des barrières de sécurité

Résistance aux intempéries et protection UV

Vous souhaitez que votre barrière de sécurité dure à l'extérieur. Pluie, soleil, et l'air salin peut le blesser avec le temps. Les revêtements résistants aux intempéries aident à protéger le métal de l'eau et du sel. Ces revêtements constituent un bouclier qui maintient votre barrière de sécurité solide. Le revêtement résistant aux intempéries W-Finish fonctionne bien dans les endroits humides et salés. Il bloque l'eau et empêche la formation de rouille. Les revêtements anticorrosion NANOMYTE protègent également votre barrière de sécurité des dommages. Ces revêtements aident votre barrière à durer plus longtemps dans les endroits difficiles.

La lumière du soleil peut faire pâlir et affaiblir une barrière de sécurité.. Les matériaux résistants aux UV maintiennent votre barrière de sécurité brillante et solide. Certains poteaux utilisent du polyéthylène basse densité avec des stabilisants UV. Ce matériau aide votre barrière de sécurité à ne pas se décolorer. D'autres postes utilisent du polyéthylène flexible avec des inhibiteurs d'ultraviolets. Ces fonctionnalités aident votre barrière de sécurité à durer plus longtemps à l'extérieur.

Conseil: Choisissez une barrière de sécurité dotée de caractéristiques résistantes aux intempéries et aux UV. Cela permet à votre barrière de rester belle et de fonctionner correctement pendant de nombreuses années..

Construction modulaire pour un remplacement facile

Une barrière de sécurité modulaire facilite la réparation. Vous ne pouvez changer que la partie cassée, pas toute la barrière. Cela vous fait gagner du temps et de l'argent. Dans un grand immeuble, vous devrez peut-être déplacer ou changer votre barrière de sécurité souvent. La conception modulaire vous permet de le faire rapidement.

Voici un tableau qui montre pourquoi les barrières de sécurité modulaires sont intelligentes:

| Avantage | Description |

|---|---|

| Économies de coûts | La conception modulaire réduit les coûts de main-d'œuvre et de matériaux pour votre barrière de sécurité. |

| Flexibilité | Vous pouvez déplacer ou changer votre barrière de sécurité selon l'évolution de vos besoins. |

| Réutilisabilité | Utilisez la même barrière de sécurité à différents endroits pour économiser de l'argent. |

Une barrière de sécurité routière modulaire contribue à assurer la sécurité de votre site. Vous pouvez résoudre les problèmes rapidement et maintenir le bon fonctionnement de votre barrière de sécurité.. Cela signifie moins d’attente et une meilleure protection pour chacun.

Postes de délinéation du trafic pour la visibilité

Films réfléchissants et couleurs haute visibilité

Les poteaux délimiteurs de trafic doivent être faciles à voir. Bright colors et les bandes brillantes aident beaucoup. Les couleurs jaune et orange ressortent rapidement. Drivers and workers notice these colors right away. These colors work well in fog or at night. Reflective films make posts even safer. Car lights hit the bands and bounce back. This makes the posts shine in dark places. Everyone can spot danger zones better.

Many posts use UV-stabilized polyethylene. This keeps colors bright for a long time. Sunlight does not make the colors fade. Some posts have two wide reflective bands. These bands are each 3 pouces de large. They meet traffic safety rules. Using these features lowers accidents by up to 80%. This helps keep workers safe in busy areas.

Conseil: Pick posts with bright colors and shiny bands. This gives your site the best safety and visibility.

Conformité aux normes de sécurité

You must follow safety rules for traffic delineator posts. Ces règles protègent les travailleurs et les conducteurs. Aux États-Unis, Mutcd sets the main rules. Posts need shiny bands and bright colors to meet these rules. De nombreux postes sont également conformes aux normes ANSI/ISEA et EN ISO 20471 normes. Ces règles nécessitent des pièces brillantes pour une meilleure visibilité.

Si vous enfreignez ces règles, votre entreprise peut recevoir de lourdes amendes. Les amendes peuvent être terminées $16,500 pour chaque erreur. Si tu continues à enfreindre les règles, les amendes deviennent encore plus lourdes. Le non-respect des règles peut provoquer des accidents ou des blessures. Choisissez des publications qui respectent toutes les règles de sécurité pour éviter les problèmes.

- Principales fonctionnalités pour suivre les règles:

- Les matériaux stabilisés aux UV gardent les couleurs vives

- Deux bandes brillantes de 3 pouces

- Les poteaux sont légers et faciles à déplacer

- Vous pouvez les installer pour une courte ou une longue durée

Utiliser les bonnes publications assure la sécurité de votre site. Vous évitez les amendes et montrez que vous vous souciez de la sécurité.

Entretien et longévité

Inspections de routine et entretien

Vous avez besoin de votre barrière de sécurité pour travailler au quotidien. Des contrôles réguliers vous aident à détecter rapidement les problèmes. Longez la barrière et recherchez les fissures ou les pièces manquantes. Assurez-vous que chaque barrière de sécurité est droite. Si vous voyez de la saleté ou des produits chimiques, nettoyer la barrière avec de l'eau et du savon doux. Cela aide votre barrière de sécurité à rester lumineuse et facile à voir. Si vous trouvez des pièces cassées, remplacez-les tout de suite.

Conseil: Prévoyez de vérifier souvent votre barrière de sécurité. Les contrôles mensuels vous aident à détecter les petits problèmes avant qu'ils ne s'aggravent. Cela garantit le bon fonctionnement de votre barrière de sécurité et assure la sécurité de tout le monde..

Voici une liste de contrôle simple pour votre barrière de sécurité:

- Recherchez des fissures ou des éclats dans la barrière.

- Vérifiez les couleurs fanées ou les bandes brillantes usées.

- Assurez-vous que chaque barrière de sécurité est stable et ne bouge pas.

- Nettoyer la saleté, huile, ou produits chimiques.

- Remplacez les pièces cassées dès que possible.

Avantages économiques au fil du temps

Choisir une barrière de sécurité solide vous fera économiser de l'argent plus tard. Les barrières en éthylène-acétate de vinyle ne rouillent pas et ne se cassent pas facilement. Cela signifie que votre barrière de sécurité dure plus longtemps et nécessite moins de réparations.. Vous passez moins de temps à réparer et plus de temps à assurer la sécurité de votre site.

Les agences de transport examinent le coût des barrières de sécurité au fil du temps. Ils constatent que de solides barrières de sécurité coûtent plus cher au début, mais vous économisez de l'argent car vous n'avez pas besoin d'en acheter de nouveaux souvent. Vous économisez également sur les réparations et la main d’œuvre. Une barrière de sécurité robuste assure la sécurité de votre site et vous aide à respecter les règles de sécurité. Vous bénéficiez d’une meilleure protection et les travailleurs restent en sécurité.

Vous pouvez rendre votre lieu de travail plus sûr en choisissant les bons messages. Choisissez des poteaux fabriqués à partir de matériaux solides. Utilisez des revêtements résistants aux intempéries pour les protéger de la pluie. Choisissez des poteaux aux couleurs vives et aux bandes réfléchissantes. Ceux-ci aident les gens à mieux les voir. Les conceptions modulaires vous permettent de remplacer rapidement les pièces cassées. Vérifiez souvent vos publications pour maintenir un niveau de sécurité élevé. Suivez les règles d'installation et d'entretien des publications. Consultez les tableaux ci-dessous pour connaître les choix de fondations et les façons d'installer les poteaux..

| Option Fondation | Caractéristiques clés |

|---|---|

| Bases en béton | Très solide et stable. Idéal pour les publications qui restent au même endroit. |

| Messages pilotés | Fonctionne bien dans de nombreux types de saletés. Reste solide par mauvais temps. |

| Ancrages à visser | Simple à mettre et à retirer. Idéal pour les messages que vous déplacez beaucoup. |

| Fondations préfabriquées | Rapide à mettre en place. Toujours fort et bien fait. |

| Bases portatives | Facile à déplacer. Idéal pour les endroits où la circulation change souvent. |

Conseil: Vérifiez toujours les règles de sécurité avant de publier de nouveaux messages. Obtenir des conseils d'experts vous aide à suivre les règles et à assurer la sécurité de tous.

FAQ

Qu'est-ce qui rend un poteau de délinéation résistant à la corrosion?

Vous bénéficiez d'une résistance à la corrosion grâce à des matériaux comme l'acier inoxydable, acier galvanisé, ou polyuréthane. Ces matériaux bloquent l'eau, produits chimiques, et le sel. Les revêtements protecteurs ajoutent une autre couche de défense. Cela permet à vos publications de durer plus longtemps dans des environnements difficiles.

Comment puis-je savoir quel matériel convient le mieux à mon site?

Vous devriez regarder les conditions de votre site. Pour les zones humides ou riches en produits chimiques, l'acier inoxydable ou l'acier galvanisé fonctionnent mieux. Pour les zones à fort impact, choisissez le polyuréthane. Demandez à un expert si vous n'êtes pas sûr.

Pourquoi les bandes réfléchissantes sont-elles importantes sur les poteaux de délinéation?

Les bandes réfléchissantes aident les conducteurs et les travailleurs à voir les poteaux la nuit ou dans des conditions de faible luminosité. Cela réduit les accidents. Les couleurs vives et les bandes réfléchissantes rendent votre site plus sûr et vous aident à respecter les règles de sécurité.

À quelle fréquence dois-je inspecter mes poteaux de délinéation?

Vous devriez vérifier vos publications au moins une fois par mois. Chercher des fissures, décoloration, ou des pièces lâches. Des inspections rapides vous aident à détecter rapidement les problèmes et à assurer la sécurité de votre site.

Puis-je remplacer une seule partie d'un poteau de délinéation modulaire?

Oui, tu peux. Les poteaux modulaires vous permettent d'échanger les sections endommagées sans supprimer l'intégralité du poteau.. Cela vous fait gagner du temps et de l'argent. Vous faites fonctionner votre barrière de sécurité avec moins d'effort.