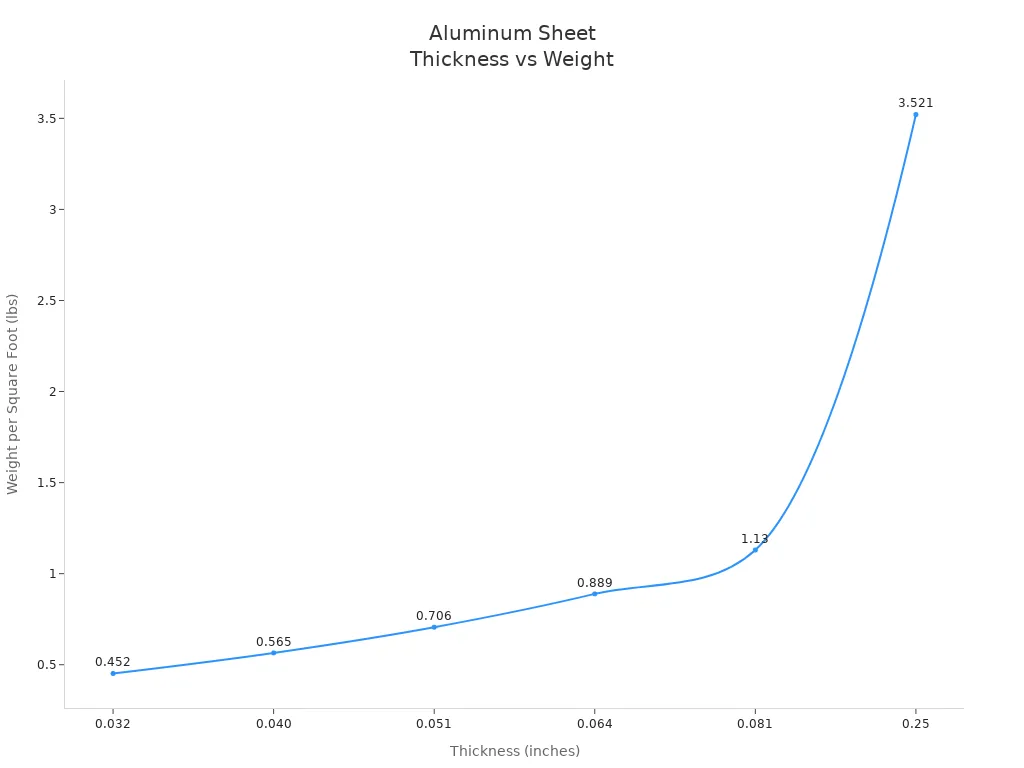

L'aluminium joue un rôle crucial dans les panneaux routiers En raison de son poids léger, force, et résistance à la rouille. Lors de la sélection des panneaux en aluminium, Il est important de considérer plusieurs facteurs qui influencent le poids de tôle en aluminium. Ces facteurs incluent l'épaisseur, taille, type en alliage, revêtements, et concevoir. Chacun de ces choix peut avoir un impact sur le coût global de votre projet, ainsi que la sécurité et la conformité réglementaire. Par exemple, L'aluminium plus épais augmente le poids de tôle d'aluminium, ce qui signifie généralement un coût plus élevé mais une plus grande durabilité. Certains alliages et revêtements améliorent également la force et la longévité du signe. Le tableau ci-dessous illustre comment l'épaisseur et le type d'alliage affectent le coût, sécurité, et installation, vous aider à déterminer la meilleure option pour vos besoins.

Épaisseur et poids de tôle en aluminium

Impact d'épaisseur

L'épaisseur est la principale chose qui change le poids de la tôle d'aluminium pour les panneaux de signalisation routière. Si vous rendez la feuille d'aluminium plus épaisse, ça devient plus lourd. Cela se produit parce que les feuilles plus épaisses ont plus de volume. Les feuilles plus épaisses sont plus fortes et durent plus longtemps. C'est bon pour les panneaux dans les endroits venteux ou sur les routes très fréquentées..

Voici un tableau qui montre comment les plages d'épaisseur correspondent aux utilisations et au poids des panneaux routiers.:

| Gamme d'épaisseur (pouce) | Application typique | Impact sur le poids et l'utilisation |

|---|---|---|

| .040" | Petites enseignes ou panneaux d'affichage intérieurs | Léger, facile à traiter, poids inférieur |

| .080" | La plupart des panneaux publicitaires extérieurs | Résistance équilibrée et poids modéré |

| .125" | Panneaux extérieurs de grande taille ou très durables | Résistance et durabilité accrues, un poids plus lourd affecte l'installation et le transport |

Quand l'épaisseur augmente, poids en tôle d'aluminium ça monte aussi. Ce changement affecte le coût et la façon dont vous vous déplacez et installez les panneaux..

Jauge et poids

Le système de jauge vous aide à savoir à quel point les feuilles d'aluminium sont épaisses. Un numéro de jauge inférieur signifie que la feuille est plus épaisse et plus lourde. Par exemple, 16 Gauge L'aluminium est à propos 0.0508 pouces d'épaisseur. Cette épaisseur donne une bonne résistance et est facile à manipuler. Il fonctionne bien pour faire des panneaux de signalisation car il peut gérer le temps et n'est pas trop lourd.

Voici une table qui montre comment la jauge correspond à l'épaisseur et au poids:

| Jauge | Épaisseur (pouces) | Épaisseur (mm) | Poids (lbs par m². ft) | Implication clé |

|---|---|---|---|---|

| 14 | ~ 0,0641 | ~ 1.63 | ~ 0,91 | Feuille plus épaisse et plus lourde, Convient à la signalisation durable |

| 16 | ~ 0,0508 | ~ 1.29 | En conséquence plus léger | Plus mince et plus léger, Équilibrer la force et la gestion |

Si vous choisissez une jauge inférieure, La feuille sera plus épaisse et pèse plus. Ce choix modifie la façon dont vous transportez et installez vos panneaux de route.

Sélection d'épaisseur

Choisir la bonne épaisseur pour votre panneau de route en aluminium Cela dépend de la taille du panneau, Emplacement d'installation, et exposition au vent. Des signes plus petits dans les zones à faible trafic peuvent utiliser des feuilles plus minces, tandis que les grands panneaux autoroutes ou aériens nécessitent un aluminium plus épais pour rester stable et conforme.

| Taille de signe (Zone) | Épaisseur de feuille d'aluminium recommandée (pouce) | Considérations clés |

|---|---|---|

| Petits signes (parking, propriété privée) | .040" (≈1,0 mm) | Léger, facile à monter; adapté à temporaire ou non-Mutcd applications |

| Signes moyens (réglementaire, pancartes) | .080" (≈20 mm) | MUTCD; Assez fort pour résister à la flexion et résister aux charges de vent normales |

| Gros signes (autoroute, guide, aérien) | .125" (≈3,2 mm) | Requis pour les zones à vent élevé; fournit une rigidité maximale mais plus lourde pour l'installation |

La plupart NOUS. panneaux routiers sont produits en .080″ En aluminium, qui équilibre la durabilité et la manipulation tout en répondant aux exigences MUTCD. .040" feuilles peut être utilisé pour les signes temporaires ou privés, alors que .125" feuilles sont choisis pour les panneaux de guidage routier surdimensionnés et les environnements côtiers où le vent et la corrosion sont des facteurs majeurs.

Dimensions et panneaux de route

Calcul de la taille et du poids

Vous devez connaître la taille de votre panneau avant de trouver son poids. La longueur et la largeur vous disent de combien d'aluminium vous avez besoin. Les signes plus gros utilisent plus d'aluminium et pèsent plus. Pour trouver le poids, Multipliez la longueur, largeur, et épaisseur ensemble. Par exemple, un signe qui est 10 pieds 12 pieds et 1/8 pouces d'épaisseur ont besoin de ces chiffres multipliés. Cela vous donne le volume total. Alors, Multipliez par la densité de l'aluminium pour obtenir le poids. Cela vous aide à planifier comment bouger et installer le signe.

Standard vs. Tailles personnalisées

Les tailles standard facilitent les projets de panneaux et plus rentables. Formats courants tels que 18″ × 24 ″, 24″ × 36 ″, et 24 "× 48" ajuster les cadres de montage standard et utiliser généralement l'aluminium plus fin (.040″ -.063"), qui réduit le poids et simplifie l'installation. Les tailles personnalisées permettent aux entrepreneurs de concevoir une forme ou une dimension, mais les plus grands panneaux nécessitent souvent .080″ Ou .125 ″ Aluminium Pour maintenir la rigidité, les rendre plus lourds et plus complexes à installer. En plus de la taille, Le type de panneau affecte également le poids. Matériau composite en aluminium (ACM) Les panneaux sont plus légers que les feuilles d'aluminium solides tout en offrant une durabilité extérieure à long terme.

| Type de panneau | Épaisseur (pouce / mm) | Poids (kg / m²) | Description |

|---|---|---|---|

| Panneau composite en aluminium | 0.16" (≈4 mm) | 6.3 - 7.6 | Deux feuilles d'aluminium minces avec un noyau en plastique, beaucoup plus léger que l'aluminium solide |

| Panneau d'aluminium solide | 0.16" (≈4 mm) | 10.8 - 15 | Feuille d'aluminium unique unique, beaucoup plus lourd |

👉 Conseil: Pour les grands panneaux de guidage ou les installations routières, Les points d'État approuvent souvent Panneaux ACM comme une alternative plus légère à l'aluminium solide, à condition que le matériel se réunit ASTM B209 et ASTM D4956 exigences.

Considérations de grandes signes

Les grands signes nécessitent une planification supplémentaire. Vous devez penser à les déplacer et à les installer. Si vous commandez de nombreux signes ou de très grosses draps, Vous rencontrez plus de problèmes. Vous pourriez avoir besoin de permis, bandes-annonces spéciales, et véhicules d'escorte. Vous devez utiliser des chaînes et des couvercles pour assurer la sécurité de l'aluminium. Vous avez également besoin d'espace pour stocker les panneaux et les empêcher de dégâts. Les panneaux composites en aluminium facilitent les grands signes car ils pèsent moins. Les panneaux en aluminium solide ont besoin de plus de personnes ou de machines pour installer, Mais ils durent plus longtemps dans des endroits difficiles. Planifiez toujours votre itinéraire et vérifiez les règles locales avant de déplacer de gros signes. Cela maintient votre projet en sécurité et à temps.

Chez OPTRAFFIC, Nous fournissons à la fois des panneaux composites en aluminium et en aluminium solides fabriqués selon les normes ASTM et MUTCD, offrir aux entrepreneurs une flexibilité pour choisir la bonne option pour l'autoroute, ville, ou projets de panneaux personnalisés. Explorez nos solutions de panneaux en aluminium.

Conseil: Choisissez des panneaux composites en aluminium pour les grands signes si vous voulez une manipulation plus facile et une installation plus rapide. Utilisez de l'aluminium solide lorsque vous avez besoin de plus de force et de durabilité.

Alliage et densité en aluminium

Types d'alliages

Lorsque vous choisissez des matériaux pour les panneaux routiers, tu vois beaucoup alliages en aluminium. Chaque alliage a des forces et des utilisations spéciales. Les points d'État et les fabricants de signes spécifient généralement 5052-H38 Aluminium pour les applications routières et côtières, car il fournit une résistance à la corrosion supérieure contre le spray salin et la pollution industrielle. 6061-T6 est utilisé lorsque les signes nécessitent une résistance structurelle supplémentaire, comme les panneaux de portières aériens, Bien qu'il soit moins formable. Pour les panneaux municipaux et de rue, 3003 et 3105 Les alliages restent populaires en raison de leur rentabilité et de leur facilité de fabrication. Ces choix d'alliage sont cohérents avec les spécifications ASTM B209 pour la feuille d'aluminium utilisée dans les infrastructures de transport.

Voici un tableau qui compare les alliages d'aluminium populaires pour les panneaux de signalisation:

| Alliage en aluminium | Densité (g / cm³) | Résumé de la résistance et des propriétés |

|---|---|---|

| 6061 (6000 série) | 2.7 | Bonne force, résistance à la corrosion, Facile à façonner, rentable, Largement utilisé pour la plupart des panneaux routiers |

| 7075 (7000 série) | 2.81 | Résistance plus élevée, plus lourd, plus cher, plus difficile de travailler avec, Utilisé pour des applications durables spécialisées |

Tu peux voir 6061 est plus léger et plus facile à utiliser. 7075 est plus lourd et plus fort mais coûte plus cher. La plupart des panneaux routiers utilisent 6061 ou 5052 Parce qu'ils équilibrent le poids, force, et le prix.

Différences de densité

La densité des alliages d'aluminium change lorsque différents éléments sont mélangés. L'ajout de cuivre ou de zinc rend l'alliage plus lourd. Le magnésium et le silicium le rendent plus léger. Ces changements affectent le poids de la tôle en aluminium. Si vous choisissez un alliage avec une densité plus faible, Votre panneau pèse moins. Cela vous aide à déplacer et à installer des signes importants ou élevés.

La plupart des alliages en aluminium pour les panneaux routiers ont une densité autour 2.7 g / cm³. C'est beaucoup plus léger que l'acier, qui dépend 7.87 g / cm³. Les panneaux en aluminium sont plus faciles à transporter et à installer. Même s'ils sont légers, Ces alliages sont encore assez forts pour les panneaux de route. Par exemple, 6061 l'alliage a une densité d'environ 2.7 g / cm³. 7075 est un peu plus lourd à 2.81 g / cm³. Le 5052 L'alliage a du magnésium, il est donc plus léger et bon pour fort, signes légers.

Conseil: Choisir un alliage avec une densité plus faible vous aide à créer des panneaux de route plus légers. Vous ne perdez pas de force ni de durabilité.

Facteurs de performance

L'alliage que vous choisissez modifie la façon dont votre panneau routier gère la météo, tubes, et le temps. Certains alliages résistent mieux à la rouille, Ce qui aide si vos signes font face à la pluie, neige, ou l'air salé. D'autres sont plus forts, afin qu'ils puissent gérer le vent ou les choses en les frappant.

Voici une table qui montre comment les différents alliages d'aluminium fonctionnent pour les panneaux routiers:

| Alliage en aluminium | Propriétés clés | Impact sur la durabilité et la résistance aux intempéries |

|---|---|---|

| 3003-H18 | Formabilité exceptionnelle, résistance à la corrosion, durabilité | Idéal pour les panneaux de signalisation; supporte diverses conditions météorologiques tout en maintenant la clarté et la longévité |

| 5052-H38 | Résistance à la traction élevée, Résistance à la corrosion supérieure | Convient aux panneaux autoroutiers exposés au trafic à grande vitesse et aux environnements durs; assure la longévité et la visibilité |

| 6061-T6 | Force et durabilité exceptionnelles | Utilisé pour les signes réglementaires nécessitant une robustesse contre les stress et les impacts environnementaux; maintient l'intégrité structurelle et la visibilité |

| 3004-H38 | Bonne formabilité et résistance à la corrosion | Favorisé pour les panneaux d'avertissement nécessitant une grande visibilité et une durabilité dans les environnements extérieurs; maintient la clarté et résiste aux conditions environnementales |

Vous devriez faire correspondre l'alliage aux besoins de votre projet. Pour Autoroutes très fréquentées ou zones côtières, 5052-H38 est un choix intelligent. Si vous voulez un panneau qui façonne et installe facilement, 6061-T6 est un bon choix. Les alliages comme 3003-H18 et 3004-H38 sont parfaits pour les panneaux de rue et d'avertissement. Ils gardent leur couleur et leur forme dans toutes sortes de temps.

Note: Choisir le bon alliage d'aluminium aide vos panneaux à durer plus longtemps et à rester facile à voir. Vous passerez moins de temps et d'argent à les réparer.

Traitements de surface et options de signe composite en aluminium

Revêtements et films

Les panneaux de route sont souvent brillants et brillants à cause des revêtements et des films. Ces couches incluent la peinture, films réfléchissants, et revêtements protecteurs. Ils aident les panneaux à se démarquer et à durer plus longtemps. Lorsque vous ajoutez ces couches, Le signe devient un peu plus lourd. Chaque couche est mince, Mais ensemble, ils ajoutent du poids, Surtout sur les grands signes. Les films réfléchissants aident les conducteurs à voir les panneaux la nuit. Les revêtements protecteurs éloignent la rouille et les rayures. N'oubliez pas de compter ces couches lorsque vous déterminez le poids final de votre signe composite en aluminium.

Composite en aluminium

Les panneaux composites en aluminium ont une conception spéciale. Ils utilisent deux feuilles d'aluminium minces avec un noyau en plastique au milieu. Cette forme de sandwich les rend beaucoup plus légers que les feuilles d'aluminium solides. Vous pouvez bouger et installer des panneaux composites en aluminium plus facilement. Le poids léger vous aide à gagner du temps et de l'argent lors de l'installation. Même s'ils sont plus légers, Les panneaux composites en aluminium sont toujours solides pour la plupart des utilisations. Vous pouvez les utiliser pour des panneaux extérieurs, affichages, et des publicités. Les feuilles d'aluminium solides sont plus fortes et résistent mieux au feu, Mais ils sont plus lourds. Les panneaux composites en aluminium ne rouillent pas et peuvent gérer le mauvais temps. Si vous voulez savoir combien de temps ils durent, c'est généralement 10 à 20 années, Selon le revêtement. Beaucoup de gens choisissent un composite en aluminium car il est facile à utiliser et dure longtemps.

Conseil: Choisissez un composite en aluminium pour les grands signes ou élevés. Cela rend l'installation plus facile et plus sûre.

Exigences réglementaires

Il y a des règles pour utiliser des revêtements et des films sur les panneaux routiers. De nombreux endroits disent que vous devez utiliser des films réfléchissants pour les panneaux de signalisation la nuit. Les revêtements sur votre panneau composite en aluminium doivent suivre les règles locales et nationales. Ces règles aident votre panneau à rester en sécurité, fort, et facile à voir par tous les temps. Vérifiez toujours les dernières règles avant d'acheter ou de mettre en place un panneau composite en aluminium. Cela garantit que votre projet est sûr et répond à toutes les normes.

Caractéristiques de conception et installation

Perforations et découpes

Vous pouvez rendre les panneaux de route en aluminium plus légers en ajoutant des trous, découpes, ou des formes spéciales. Lorsque vous utilisez des conceptions comme des coupes de cercle, coupes ovales, ou trous percés, vous retirez une partie du métal. Cela réduit le poids total du signe. Même avec moins de matériel, Le signe peut toujours rester fort et garder sa forme. Les formes et les perforations personnalisées vous permettent de faire correspondre le signe à son objectif tout en facilitant la gestion. Par exemple, Les panneaux avec des trous de montage ou des contours uniques pèsent moins et sont plus simples à installer, surtout sur de grands poteaux ou dans des endroits difficiles à atteindre.

Conseil: Utilisez des découpes et des perforations pour réduire le poids des grands signes sans perdre la durabilité.

Sécurité d'installation

Le poids de votre panneau en aluminium affecte la façon dont vous l'installez et quel équipement vous avez besoin. Les panneaux plus légers sont plus faciles à transporter, ascenseur, et monter. Vous pouvez souvent utiliser des outils simples et moins de personnes. Les signes plus lourds peuvent nécessiter un équipement spécial, comme les ascenseurs ou les grues, et plus de travailleurs pour une installation sûre. Pour assurer la sécurité de votre projet et suivre les règles locales, tu devrais:

- Obtenez les bons permis avant de commencer l'installation.

- Suivez les règles de placement pour la hauteur et la distance de la route.

- Utilisez des matériaux approuvés et du matériel de montage.

- Assurez-vous que le panneau est stable et visible.

- Des panneaux en aluminium léger vous permettent d'utiliser des supports pliables ou des supports de montage de base.

- Vous pouvez les installer rapidement, ce qui permet d'économiser le temps et de réduire les coûts de main-d'œuvre.

Durabilité dans les panneaux routiers

Choisir le bon poids pour votre panneau aide à durer plus longtemps et à protéger les routes. L'aluminium résiste à la rouille et résiste au vent, pluie, et le soleil. Si vous choisissez un signe trop léger, il pourrait se plier ou se casser par temps fort. Si c'est trop lourd, Il peut être difficile à installer et peut avoir besoin d'un support supplémentaire. Une bonne sélection de poids signifie que votre panneau reste visible et fort pendant des années. Cela aide les conducteurs à voir des informations importantes et à faire avancer le trafic en toute sécurité.

Note: Durable, Les panneaux bien montés protègent les conducteurs et votre investissement en réduisant le besoin de réparations ou de remplacements.

Lorsque vous choisissez des draps en aluminium pour les panneaux de signalisation, Réfléchissez à l'épaisseur, taille, alliage, revêtements, et concevoir. Ces choses changent à quel point, fort, Et dur, la feuille est. Utilisez cette liste de contrôle pour vous aider à choisir:

- Choisissez une qualité d'aluminium qui ne rouille pas.

- Assurez-vous que le fournisseur suit les règles de sécurité.

- Vérifiez si l'épaisseur et la réflectivité sont autorisées.

- Recherchez des fonctionnalités faciles à installer comme des trous déjà frappés.

- Voir si le fournisseur est fiable et offre une garantie.

Vous pouvez demander de l'aide aux experts pour trouver le meilleur matériel pour votre projet, météo, et le budget. Cela garantit que vos signes sont sûrs et suivent les règles à chaque fois. Chez OPTRAFFIC, Notre équipe fournit feuilles en aluminium et solutions de signalisation de la circulation qui respectent les normes MUTCD et ASTM, Aider les entrepreneurs et les municipalités à réaliser des projets en toute sécurité, à l'heure, et dans le budget.

FAQ

Quelle est la meilleure épaisseur pour les panneaux de route en aluminium?

Pour les panneaux routiers conformes à MUTCD aux États-Unis, 0.080-Les feuilles d'aluminium de pouces sont la norme de l'industrie, Comme recommandé par la Federal Highway Administration (Fhwa). Certains États, tel que Texas Dot et Dot de Floride, Acceptez également des panneaux de 0,125 pouce pour les grands panneaux de guidage sur autoroute pour répondre aux exigences de chargement de vent plus élevées. Pour un parking plus petit ou des panneaux de propriété privée, .040-L'aluminium de pouces peut être suffisant, Mais ceux-ci ne rencontrent pas Mutcd pour les routes publiques.

Comment calculer le poids d'une feuille en aluminium pour mon signe?

Multipliez la longueur, largeur, et épaisseur pour obtenir le volume. Alors, Multipliez le volume par la densité de l'aluminium (2.7 g / cm³). Cela vous donne le poids total.

Conseil: Utilisez une calculatrice en ligne pour des résultats rapides.

Les revêtements et les films ajoutent beaucoup de poids aux panneaux en aluminium?

Les revêtements et les films ne ajoutent qu'une petite quantité de poids. Pour la plupart des signes, Ce poids supplémentaire n'affecte pas la manipulation ou l'installation. Vous obtenez toujours une meilleure visibilité et protection.

Sont des panneaux composites en aluminium plus légers que les feuilles d'aluminium solides?

Oui, Les panneaux composites en aluminium pèsent moins. Ils utilisent un noyau en plastique entre deux feuilles d'aluminium minces. Cette conception les rend plus faciles à soulever et à installer.

Pourquoi le type d'alliage est-il important pour le poids des panneaux routiers?

Différents alliages ont des densités et des forces différentes. Certains alliages rendent votre signe plus léger et plus résistant à la rouille. Choisir le bon alliage aide votre signe à durer plus longtemps et rester en sécurité.