Reflektierblatt der Ingenieur -Klasse ist eine billige und vertrauenswürdige Wahl für Schilder in vielen Städten. Städte und Gruppen wählen dieses Material häufig für reflektierende Verkehrszeichen aus. Es gibt einen guten Preis und lässt die Leute immer noch die Zeichen gut sehen. Viele Unternehmen, die reflektierende Verkehrszeichen verkaufen, Wie Ingenieur -Note, ist mehr als die Hälfte dessen, was die Leute kaufen. Dies liegt daran, dass es nicht teuer ist und lange dauert.

- Regierungen und Orte, die Geld sparen müssen, verwenden dies häufig für Schilder. Sie wollen gute Schilder, wollen aber auch weniger ausgeben.

- Durch bessere Herstellungsverfahren sind reflektierende Folien in technischer Qualität noch besser geworden. Es ist jetzt die erste Wahl für Zeichen, die nicht sehr wichtig sind, wo es am wichtigsten ist, Geld zu sparen.

Dieses Material trägt dazu bei, dass Verkehrsschilder gut sichtbar sind und Schilderprojekte im Rahmen des Budgets gehalten werden. Erfahren Sie mehr über die Auswahl der besten reflektierenden Materialien für Sicherheitsschilder zum Verkauf, Schauen Sie sich den OPTRAFFIC-Blog an So wählen Sie die besten reflektierenden Materialien für Verkehrszeichen aus. Dieser Leitfaden bietet wertvolle Einblicke in die Auswahl der richtigen Materialien unter Berücksichtigung der Sicherheit, Sichtweite, und Budgetüberlegungen.

Key Takeaways

- Reflektierende Folien in technischer Qualität sind eine kostengünstige Möglichkeit, Verkehrszeichen gut sichtbar zu machen. Es funktioniert am besten auf lokalen Straßen und Straßen, die nicht sehr stark befahren sind. Dieses Material besteht aus winzigen Glasperlen, die das Licht zum Fahrer zurückwerfen. Dadurch können Menschen nachts und bei schlechtem Wetter Schilder besser erkennen. Es ist stark und hält Regen stand, Sonne, und Wind. Es kann dauern 7 Zu 10 Jahre, wenn man sich darum kümmert. Sie sollten für jede Straße die richtige reflektierende Folie auswählen. Die Wahl hängt davon ab, wie wichtig die Straße ist und wie viel Verkehr sie hat. Der Grad „Ingenieur“ eignet sich für Schilder, die nicht sehr wichtig sind. Durch die Verwendung von Planen in Ingenieurqualität können Sie bei großen Projekten Geld sparen. Außerdem sorgt es für sichere Straßen und macht die Schilder gut sichtbar.

Was ist reflektierende Folie in Ingenieurqualität??

Retroreflektierende Technologie

Reflektierende Folie in Ingenieurqualität nutzt eine spezielle retroreflektierende Technologie, um die Sicherheit im Straßenverkehr zu gewährleisten. Bei dieser Technologie werden winzige Glasperlen verwendet, die Licht einfangen und zurücksenden. Wenn Autoscheinwerfer auf ein Schild treffen, Die Perlen reflektieren das Licht zurück zum Fahrer. Dadurch sind Verkehrszeichen nachts oder bei schlechtem Wetter deutlich besser zu erkennen.

Der Texas Transportation Institute hat ein Modell entwickelt, um zu testen, wie gut retroreflektierende Materialien für Autofahrer funktionieren. Das Modell verwendet Scheinwerferformen und -winkel, um Regeln dafür festzulegen, wie hell Schilder sein sollten. Dadurch wird sichergestellt, dass reflektierende Folien für Autofahrer in vielen Situationen funktionieren.

Reflektierende Folien leiten das Licht dorthin zurück, wo es herkommt, anstatt es überall zu verteilen. Dadurch können Autofahrer die Schilder jederzeit erkennen und andere werden nicht geblendet. Unternehmen, die reflektierende Schilderfolien herstellen, nutzen diese Ideen, um strenge Sicherheitsvorschriften einzuhalten.

Materialzusammensetzung

Eine Plane in Ingenieurqualität besteht im Wesentlichen aus zwei Dingen: Mikroglasperlen und Polymerfilme. Die Fabrik verpackt Millionen winziger runder Glasperlen in eine starke Kunststofffolie. Dadurch entsteht eine Oberfläche, die das Licht jedes Mal gut reflektiert.

- Die Kunststofffolie hält die Glasperlen fest und bewahrt sie sicher auf.

- Durch die Glasperlen ist die Folie stark reflektierend, Dadurch heben sich Schilder hervor, wenn es dunkel ist.

- Durch die Verwendung beider Materialien bleibt die Folie erschwinglich, gut arbeiten, und lange lange Zeit.

Eine normale Rolle reflektierender Folie in technischer Qualität ist ca 1.24 Meter breit und 45.7 Meter lang. Es wiegt ca 0.600 Kilogramm. Diese Größen erleichtern den Arbeitern die Verwendung des Materials für viele Arten von Schildern. Reflektierende Folien für Verkehrsschilder müssen bestimmte Regeln hinsichtlich ihrer Helligkeit und Robustheit erfüllen, Deshalb arbeiten die Hersteller hart daran, dass die Perlen gut an der Folie haften.

Haltbarkeitsfunktionen

Reflektierende Folien müssen auch bei rauem Wetter draußen halten. Technische Folien verfügen über spezielle Beschichtungen, um sie vor Regen zu schützen, Sonne, und Feuchtigkeit. Diese Beschichtungen verhindern, dass das Material ausbleicht, knacken, oder sich mit der Zeit ablösen.

- Wetterfeste Beschichtungen sorgen dafür, dass die Folie hell und funktionstüchtig bleibt, auch nach Jahren in der Sonne und im Regen.

- Der UV-Schutz verhindert das Ausbleichen von Farben und Glanz, Schilder bleiben also leicht zu lesen.

- Durch die Kunststofffolie lässt sich die Folie an verschiedene Formen anpassen, ohne ihren Glanz zu verlieren.

Verkehrsschilder aus diesem Material eignen sich gut für Schilder, die nicht besonders wichtig sind. Das Design und die Beschichtungen tragen dazu bei, die Kosten und die Haltbarkeit der Folie in Einklang zu bringen, Daher sind reflektierende Folien in Ingenieurqualität für viele Aufgaben eine kluge Wahl.

Arten von reflektierenden Folien für Verkehrszeichen

Ingenieurgrad vs. Andere Noten

Es gibt verschiedene Arten von reflektierenden Folien für Verkehrsschilder. Jede Art hat ihre eigene Aufgabe und Besonderheiten. Reflektierende Folie in technischer Qualität verwendet Mikroglasperlen, um das Licht zurückzuwerfen. Es ist nicht zu teuer und funktioniert gut. Viele Städte verwenden es für Schilder, wo die Menschen sie sehen müssen, aber es ist nicht der wichtigste Ort.

Prismatische reflektierende Folie mit hoher Intensität verwendet Prismen, um mehr Licht zu reflektieren. Dieser Typ ist heller als der Ingenieurtyp. Es eignet sich gut für stark befahrene Straßen oder Orte, an denen Schilder von weitem sichtbar sein müssen. Bei Diamantfolien werden Vollwürfelprismen verwendet. Es wird auch ASTM Typ IX oder XI genannt. Dieser Typ ist der hellste und am einfachsten zu erkennende, auch bei hartem Wetter.

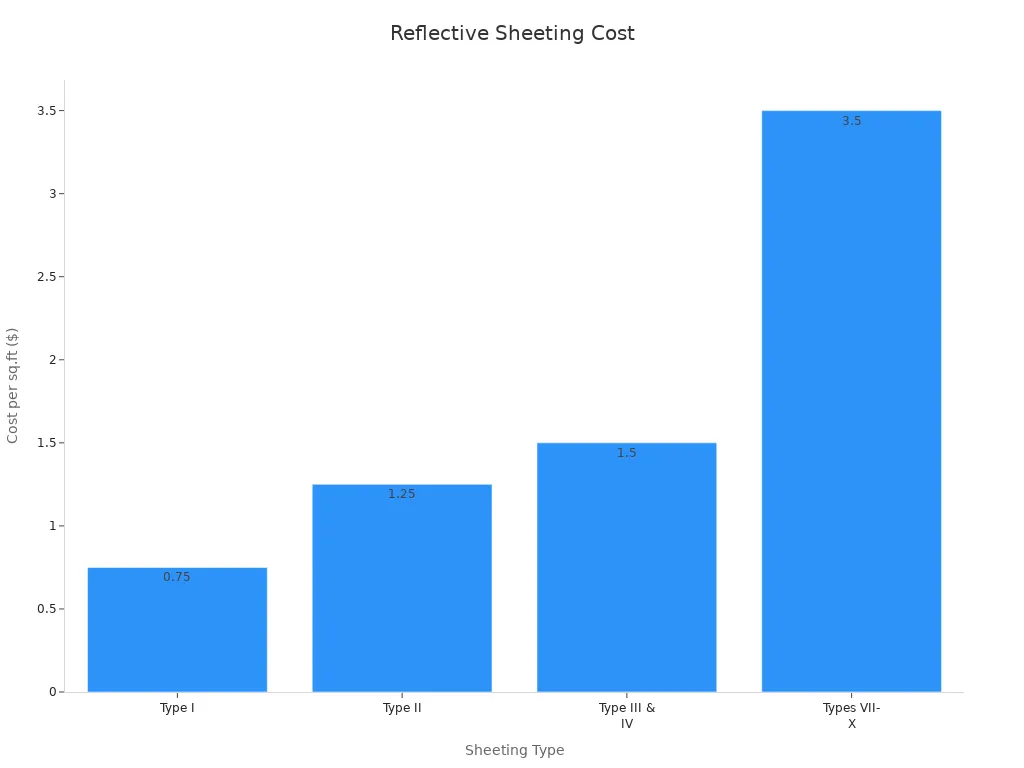

Der Zentrum für Verkehrsforschung und -bildung habe diese Typen studiert. Sie fanden heraus, dass die Verwendung einer besseren Folie die Unfallzahlen senken kann. Sioux City, Iowa, hatte 38% weniger Abstürze nach Verwendung höherer Qualitäten. Die folgende Tabelle zeigt, wie viel jeder Typ kostet und wie lange er hält:

| Blattart | Kosten pro Quadratmeter. ft. (ca.) | Erwartete Lebensdauer des Zeichens (Jahre) | Relative Kostensteigerung |

|---|---|---|---|

| Typ I | $0.75 | 5 | Grundlinie |

| Typ II | $1.25 | 10 | Moderater Anstieg |

| Typ III & Iv | $1.50 | 15 | Höherer Anstieg |

| Typen VII-X | $3.50 | 15+ | Höchster Anstieg |

In einem Forschungsartikel heißt es, dass das Alter des Schildes und die Marke der Folie eine Rolle spielen. Diese Dinge verändern mit der Zeit, wie gut die Folie funktioniert. Dies hilft Gruppen zu wissen, wann Schilder repariert oder geändert werden müssen.

Wann man die einzelnen Typen verwenden sollte

Die Auswahl der richtigen reflektierenden Folie hängt davon ab, was Sie benötigen. Reflektierende Folien in Ingenieurqualität eignen sich gut für lokale Straßen und ruhige Orte. Es spart Geld und lässt die Menschen trotzdem die Zeichen sehen. Prismenreflektierende Folien mit hoher Intensität eignen sich besser für stark befahrene Straßen. Es hilft Autofahrern, nachts und bei schlechtem Wetter Schilder zu erkennen.

Für wichtige Stellen eignet sich am besten eine Diamantfolie. Das sind Autobahnen, stark befahrene Kreuzungen, und Orte mit vielen Unfällen. Es ist am hellsten und hält am längsten. Gruppen prüfen oft alle Kosten, bevor sie sich entscheiden. Sie denken über den Kauf nach, aufstellen, Festsetzung, und wechselnde Vorzeichen. Dies hilft ihnen, die beste Plane für den Auftrag auszuwählen und Geld zu sparen.

Tipp: Gruppen sollten die richtige Folie auswählen, je nachdem, wo das Schild angebracht ist und wie wichtig es ist. Dies sorgt für die Sicherheit der Menschen und hilft, die Kosten für alle Schilder zu kontrollieren.

Anwendungen von reflektierenden Folien in Ingenieurqualität

Lokale und Wohnstraßen

Reflektierende Folien in technischer Qualität tragen dazu bei, die örtlichen Straßen sicherer zu machen. Viele Städte verwenden dieses Material für Schilder, weil es hell und günstig ist. Autofahrer können diese Schilder Tag und Nacht sehen. Dies trägt dazu bei, Verwirrung zu vermeiden und sorgt für die Sicherheit der Menschen. Eine Studie ergab, dass die Verwendung dieser Folie auf STOP-Schildern zu weniger Unfällen führte. In South Carolina, es gab weniger Auffahrunfälle. In Connecticut und South Carolina, Auch an dreigleisigen Kreuzungen kam es zu weniger Unfällen. Die größten Vorteile ergaben sich auf Straßen mit weniger Verkehr. Schon ein kleiner Rückgang der Abstürze lohnt sich. Aus diesem Grund wählen viele Städte diese Folie für ihre Verkehrsschilder.

Unkritische und temporäre Beschilderung

Reflektierende Folien in Ingenieurqualität eignen sich gut für Schilder, die nicht sehr wichtig sind oder nur für kurze Zeit benötigt werden. Bauzonen, Umwege, und Veranstaltungsparkplätze verwenden diese Schilder. Sie müssen nicht die hellsten sein, einfach leicht zu erkennen. Agenturen mögen dieses Material, weil es stark und nicht teuer ist. Arbeiter können diese Schilder schnell auf- und abbauen. Dies hilft, wenn sich Straßen ändern, und hält Projekte am Laufen. Die Folie ist hell genug, um den Fahrern beim Wechseln Sicherheit zu bieten. Es spart auch Geld für andere wichtige Bedürfnisse.

Notiz: Durch die Verwendung von reflektierenden Folien in technischer Qualität für kurzfristige Schilder können Behörden mehr für wichtige Bereiche ausgeben und dennoch die Sicherheit der Menschen gewährleisten.

Vorschrifts- und Informationszeichen

Viele Gruppen verwenden reflektierende Folien in Ingenieurqualität für Regel- und Hinweisschilder auf Straßen mit wenig Verkehr. Der MUTCD sagt, dass Folie vom Typ I für Schilder mit Weiß in Ordnung ist, Grün, oder rote Hintergründe. Dazu gehören STOP-Schilder und Parkregeln. Agenturen befolgen diese Regeln, um sicherzustellen, dass die Schilder hell genug sind. Dies sorgt für sichere Straßen und hilft Fahrern, jederzeit klare Informationen zu erhalten. Agenturen denken auch darüber nach, wie lange die Folie hält und wie viel sie kostet. Dies trägt dazu bei, dass die Schilder lange gut funktionieren.

Vorteile der reflektierenden Folie in Ingenieurqualität

Kosteneffizienz

Reflektierende Folien in technischer Qualität sind eine kluge Wahl, um Geld zu sparen. Städte und Gruppen entscheiden sich für dieses Material, weil es gut funktioniert und weniger kostet. Es ist günstiger als andere Typen, Daher eignet es sich gut für große Projekte oder Orte mit kleinem Budget. Viele Gruppen verwenden diese Folie für Schilder an weniger belebten Orten. Sie können mehr Schilder anbringen, ohne zusätzliches Geld auszugeben. Dadurch wird sichergestellt, dass jede Straße und Ecke mit einem Schild versehen ist. Es trägt auch dazu bei, öffentliche Gelder bestmöglich zu nutzen und gleichzeitig die Sicherheit der Menschen zu gewährleisten. Die Folie hält ziemlich lange, Daher müssen die Schilder nicht oft ausgetauscht werden. Das bedeutet, dass die Reparatur und der Austausch von Schildern im Laufe der Jahre weniger kosten.

Tipp: Durch die Verwendung von reflektierenden Folien in technischer Qualität können Projektleiter ihr Geld sinnvoll ausgeben. Sie können die teureren Materialien für Orte einsparen, die besser gesehen werden müssen.

Sichtbarkeit und Sicherheit

Das Erkennen von Schildern ist für die Sicherheit im Straßenverkehr von großer Bedeutung. Reflektierende Folien in technischer Qualität verwenden winzige Glasperlen, um das Licht zurückzuwerfen. Dies hilft Fahrern, Schilder nachts oder bei schlechtem Wetter zu erkennen. Die Schilder sind leicht zu erkennen, Dies trägt in vielen Situationen zur Sicherheit des Fahrers bei.

- Leitkegel mit dieser Folie haben dazu beigetragen, die Zahl der nächtlichen Unfälle um bis zu 10 % zu senken 30% in Arbeitszonen.

- Die Glasperlen helfen Autofahrern, Schilder aus der Ferne zu erkennen, So haben sie mehr Zeit zum Reagieren.

- Studien zeigen weniger Unfälle und mehr Vertrauen der Fahrer, wenn diese Kegel verwendet werden.

- Bei einem Straßenprojekt kam es nach dem Einsatz dieser Kegel zu weniger nächtlichen Unfällen.

- Bei einem städtischen Straßenprojekt wurden diese Kegel eingesetzt, um Verwirrung und Unfälle zu verhindern.

3Die reflektierende Folie M™ Engineer Grade entspricht den Typ-I-Regeln. Es verleiht Schildern an Orten mit viel Verkehr ein gutes Reflexionsvermögen. Auch wenn eine bessere Beplankung die Zahl der Unfälle verringern kann 25% Zu 46%, Ingenieurqualität trägt immer noch dazu bei, die Straßen sicherer zu machen. Diese Fakten zeigen, dass reflektierende Folien eine gute Möglichkeit sind, Straßen sicherer zu machen.

Installation und Wartung

Reflektierende Folien in technischer Qualität sind einfach zu verwenden und zu pflegen. Das Material lässt sich biegen und passt auf viele Schilderformen, So können Arbeiter es schnell auf verschiedenen Schildern anbringen. Dies beschleunigt die Anbringung von Schildern und spart Arbeitskosten. Wartungsarbeiter schätzen die Robustheit dieser Folie. Es verfügt über spezielle Schichten, die es vor Regen schützen, Sonne, und Wasser, Schilder bleiben also lange hell. Wenn Schilder geändert werden müssen, es ist einfach und kostet nicht viel. Arbeiter können Schilder schnell austauschen, ohne dass es zu Problemen kommt. Ein guter Plan für die Anbringung von Schildern sorgt dafür, dass diese gut sichtbar sind und trägt zur Sicherheit auf den Straßen bei. Die Auswahl von reflektierenden Folien in Ingenieurqualität bietet Gruppen eine starke und einfache Möglichkeit, Schilder zu handhaben und dafür zu sorgen, dass sie gut funktionieren.

Kosten-Nutzen-Analyse

Anschaffungs- und Lebenszykluskosten

Reflektierende Folien in technischer Qualität bieten für viele Schilderprojekte ein gutes Angebot. Es kostet zunächst weniger als höherwertige Materialien. Viele Gruppen entscheiden sich für diese Plane, weil sie mehr Plätze abdecken können und das Budget nicht überschreiten. Im Laufe der Zeit, Durch die Investition in gute reflektierende Beschichtungen können Sie Geld sparen. Zum Beispiel:

- Eine Lebensmittelfabrik zahlte 15% Zuerst mehr für besser reflektierende Materialien. Das hat gespart 30% Wir sparen jedes Jahr Energie und sorgen dafür, dass die Wartung doppelt so lange dauert. Über 20 Jahre, sie haben gerettet 25% auf die Gesamtkosten.

- Ein Versandzentrum ausgegeben 10% mehr für bessere Isolierung und dickeren Stahl. Dadurch konnten die Energiekosten gesenkt werden 40% und hat sich amortisiert 6 Jahre.

- Ein Bürogebäude verbraucht 12% mehr am Anfang für eine bessere Wasserdichtigkeit. Dadurch verringerten sich Reparaturen und Wasserschäden 30 Jahre.

Diese Beispiele zeigen, dass eine höhere Zahlung zunächst weniger Ersatz und später niedrigere Kosten bedeuten kann. Dies macht reflektierende Folien in technischer Qualität auf lange Sicht zu einer klugen Wahl.

Leistung unter realen Bedingungen

Reflektierende Folien in technischer Qualität funktionieren an vielen Orten im wirklichen Leben gut. Städte und Gruppen sagen, dass Schilder aus diesem Material jahrelang leuchtend und stark bleiben. Die Beschichtungen halten schlechtes Wetter und Sonne ab, damit die Schilder nicht schnell verblassen oder sich ablösen. Dies bedeutet, dass die Arbeiter weniger Zeit und Geld für die Reparatur von Schildern aufwenden müssen. Schilder auf örtlichen Straßen, Parkplätze, und Nachbarschaften halten oft so lange, wie sie sollten. Dies trägt dazu bei, die Straßen sicher zu halten und die Budgets stabil zu halten.

Tipps zur Budgetzuweisung

Projektleiter können ihr Geld noch besser verdienen, indem sie an weniger wichtigen Stellen reflektierende Folien in technischer Qualität verwenden. Sie können die besten Materialien für Autobahnen oder stark befahrene Straßen einsparen. Die Planung sowohl der ersten als auch der zukünftigen Kosten hilft Teams, Geld sinnvoll einzusetzen. Gute Daten und intelligente Designentscheidungen machen jeden Dollar wertvoll. Gruppen, die dies tun, sparen oft Geld und erhalten mit der Zeit bessere Schilder.

Wählen Sie reflektierende Folie in Ingenieurqualität

Projekteignung

Bei der Auswahl von reflektierenden Folien in Ingenieurqualität, Sie müssen wissen, was das Projekt benötigt. Dieses Material eignet sich am besten für Schilder auf örtlichen Straßen und ruhigen Straßen. Es eignet sich auch gut für Orte, an denen nicht viele Autos vorbeifahren. Agenturen verwenden es für Schilder, die nicht besonders wichtig sind, wie Park- oder Geschwindigkeitsbegrenzungsschilder. Es wird auch für spezielle Nachbarschaftsschilder verwendet. Diese Zeichen müssen nicht die hellsten sein, Aber sie tragen dennoch dazu bei, die Straßen sicher zu halten. Die Folie in Ingenieurqualität eignet sich auch hervorragend für Veranstaltungsschilder oder Schilder, die nur für kurze Zeit benötigt werden. Das Material ist flexibel, So können Teams verschiedene Formen und Größen herstellen. Dies macht es zu einer klugen Wahl für viele Straßenarbeiten.

Tipp: Wenn Sie Geld sparen und trotzdem die Straßen sicher halten möchten, Reflektierende Folie in Ingenieurqualität ist eine gute Wahl.

Konformität und Standards

Es ist sehr wichtig, die Regeln für Verkehrszeichen zu befolgen. Reflektierende Folien in technischer Qualität erfüllen viele wichtige Standards:

- Das Bundesregister besagt, dass Schilder mit Ingenieursqualität versehen sind (Typ I) Die Folie muss alle ersetzt werden 7 Jahre für die meisten Zeichen und alle 10 Jahre für Straßennamen und Überkopfschilder.

- Agenturen haben 2 Jahre, um Schilder zu überprüfen und solche zu finden, die nicht hell genug sind.

- ASTM D4956-04 erklärt, was retroreflektierende Folie ist und besagt, dass es mindestens Typ I sein muss 65 CD/LX/m².

- Der MUTCD Abschnitt 2A.08 sagt, dass die Behörden die Schilder hell genug halten und zugelassene Methoden zur Überprüfung nutzen müssen, wie in die Nacht zu schauen oder das Schild zu messen.

- Die FHWA gibt Termine und Regeln für die Einhaltung dieser Standards vor.

Diese Regeln zeigen, dass reflektierende Folien in technischer Qualität für viele Verkehrszeichen sicher und vertrauenswürdig sind.

Umweltüberlegungen

Bei der Auswahl der Folien spielt das Wetter eine große Rolle. Reflektierende Folien in technischer Qualität funktionieren an den meisten Orten gut, auch dort, wo es regnet oder die Sonne scheint. Es macht sich auch gut, wenn sich das Wetter ein wenig ändert. Die speziellen Beschichtungen verhindern das Ausbleichen und schützen vor UV-Strahlen. Dadurch bleiben die Schilder hell und gut lesbar. Wenn an einem Ort wirklich raues Wetter herrscht, Agenturen können sich vor ihrer Auswahl das lokale Wetter ansehen. Die meiste Zeit, Planen in Ingenieurqualität halten lange und tragen zur Sicherheit der Straßen bei. Für besondere Wetteranforderungen können individuelle Schilder angefertigt werden, damit jedes Projekt gut funktionieren kann.

Fallstudien: Reflektierende Verkehrszeichen in Aktion

Beispiel für ein Wohngebiet

Eine Stadt im Mittleren Westen wünschte sich bessere Schilder in den Stadtvierteln. Das Team musste die Straßen sicherer machen, hatte aber wenig Geld. Als Stopper wählten sie reflektierende Folie in technischer Qualität, Geschwindigkeitsbegrenzung, und Straßennamenschilder. Dieses Material half den Menschen, die Schilder gut zu erkennen und die örtlichen Regeln einzuhalten.

Projektziele waren:

- Sorgen Sie dafür, dass die Schilder nachts für Autofahrer und Fußgänger besser erkennbar sind.

- Nutzen Sie eine kostengünstigere Möglichkeit, viele Schilder zu ersetzen.

- Lassen Sie Schilder in speziellen Formen für jeden Bereich anfertigen.

Die Stadt arbeitete mit einer Firma zusammen, um für einige Ecken spezielle Schilder anzufertigen. Arbeiter brachten alle Schilder in weniger als zwei Wochen an. Die dort lebenden Menschen sahen, dass die Schilder nachts heller waren. Bei der Stadtverwaltung gingen weniger Beschwerden über schwer erkennbare oder fehlende Schilder ein. Das Projekt kostete weniger als geplant. Das Gleiche will die Stadt bald auch für weitere Straßen tun.

Notiz: Maßgeschneiderte Schilder helfen Stadtteilen, Sicherheitsprobleme zu beheben, ohne zu viel auszugeben.

Beispiel für ein Industriegebiet

Ein Logistikpark in der Nähe einer großen Autobahn benötigte neue Verkehrsschilder. Viele LKWs und Lieferwagen fuhren Tag und Nacht dorthin. Führungskräfte wollten Schilder, die langlebig sind und schlechtem Wetter standhalten. Für Regel- und Wegweiser auf jeder Straße im Park verwendeten sie reflektierende Folien in Ingenieurqualität.

Hauptziele des Projekts:

- Helfen Sie den Fahrern, sich zurechtzufinden, und vermeiden Sie Verwirrung.

- Machen Sie spezielle Schilder für Ladestellen und Bereiche mit Regeln.

- Bringen Sie schnell Schilder an, damit die Arbeit im Park nicht unterbrochen wird.

Das Team bekam Schilder mit gut lesbaren Bildern und Firmenlogos. Arbeiter brachten die Schilder an einem Wochenende an, Daher blieb der Park geöffnet. Nach den neuen Schildern, Fahrer verpassten weniger Abbiegungen. Die Manager stellten fest, dass sich der Verkehr besser bewegte. Das Projekt zeigte, dass reflektierende Folien in Ingenieurqualität in stark frequentierten Arbeitsbereichen gut funktionieren.

Reflektierende Folien in Ingenieurqualität sind eine gute Wahl für Schilder, die nicht sehr wichtig sind. Es hilft den Menschen, die Zeichen zu erkennen, und kostet nicht zu viel. Viele Arbeiter sparen bei Projekten Geld, sorgen aber trotzdem für die Sicherheit der Straßen. Teams sollten darüber nachdenken, was das Projekt benötigt, wie viel Geld sie haben, und wie das Wetter ist, bevor Sie Materialien auswählen.

EGS ist eine kluge Wahl, wenn Sie Schilder erkennen und Geld sparen möchten.

- Schauen Sie sich jedes Projekt genau an

- Verwenden Sie für jeden Ort das beste Material

- Denken Sie immer an Sicherheit und Geldsparen

FAQ

Wofür werden reflektierende Folien in Ingenieurqualität verwendet??

Reflektierende Folien in Ingenieurqualität eignen sich gut für örtliche Straßen und Parkplätze. Es wird auch für Zeichen verwendet, die nicht sehr wichtig sind. Städte und Unternehmen entscheiden sich für dieses Material, weil es hell und nicht teuer ist. Viele Menschen vertrauen bei diesen Aufgaben einem Anbieter von reflektierenden Verkehrsschildern.

Wie lange hält eine reflektierende Folie in technischer Qualität??

Die meisten reflektierenden Folien in technischer Qualität halten 7 Zu 10 Jahre. Wie lange es dauert, hängt vom Wetter und der Sonne ab. Es kommt auch darauf an, wie gut es aufgestellt ist. Die Überprüfung von Schildern trägt oft dazu bei, dass sie hell und funktionstüchtig bleiben.

Können reflektierende Folien in technischer Qualität die gesetzlichen Standards erfüllen??

Ja, es kann. Reflektierende Folien in Ingenieurqualität erfüllen wichtige Regeln wie ASTM D4956 Typ I und MUTCD. Agenturen und Bauunternehmer sprechen mit einem Hersteller von reflektierenden Schilderfolien, um sicherzustellen, dass die Regeln für jeden Auftrag eingehalten werden.

Wer sollte die Verwendung von reflektierender Folie in Ingenieurqualität in Betracht ziehen??

Projektmanager und Stadtplaner sollten über dieses Material nachdenken. Anlagenbetreiber können es für Schilder einsetzen, die keine große Bedeutung haben oder nur für kurze Zeit benötigt werden. Das spart Geld und ermöglicht es Autofahrern und Fußgängern trotzdem, die Schilder zu erkennen.

Wie wählen Sie einen zuverlässigen Lieferanten für reflektierende Verkehrsschilder aus??

Ein guter Lieferant stellt zertifizierte Materialien zur Verfügung und hilft bei Fragen. Sie verschicken auch Bestellungen schnell. Viele Gruppen wählen einen Anbieter mit viel Erfahrung und einem guten Namen. Ein Blick auf Rezensionen und die Prüfung von Garantien hilft dabei, sicherzustellen, dass Sie gute Produkte erhalten.