Verkehrskegel spielen eine wichtige Rolle bei der Gewährleistung der Sicherheit während der mobilen Erhöhung der Arbeitsplattform (MEWP) Operationen. Sie können damit klare Grenzen schaffen, die Arbeiter schützen und Fahrzeuge leiten. Diese Kegel helfen bei der Organisation von Arbeitsbereichen, indem sie Bereiche für bestimmte Aktivitäten markieren. Außerdem leiten sie den Verkehr von Gefahrenstellen weg, Reduzierung des Unfallrisikos. Durch die Verwendung von Sicherheitskegeln aus Kunststoff, Sie richten sichtbare Zonen ein, die sowohl Arbeiter als auch Autofahrer schützen. Dieses einfache Tool verwandelt chaotische Websites in strukturierte Umgebungen, Dadurch wird der Betrieb reibungsloser und sicherer.

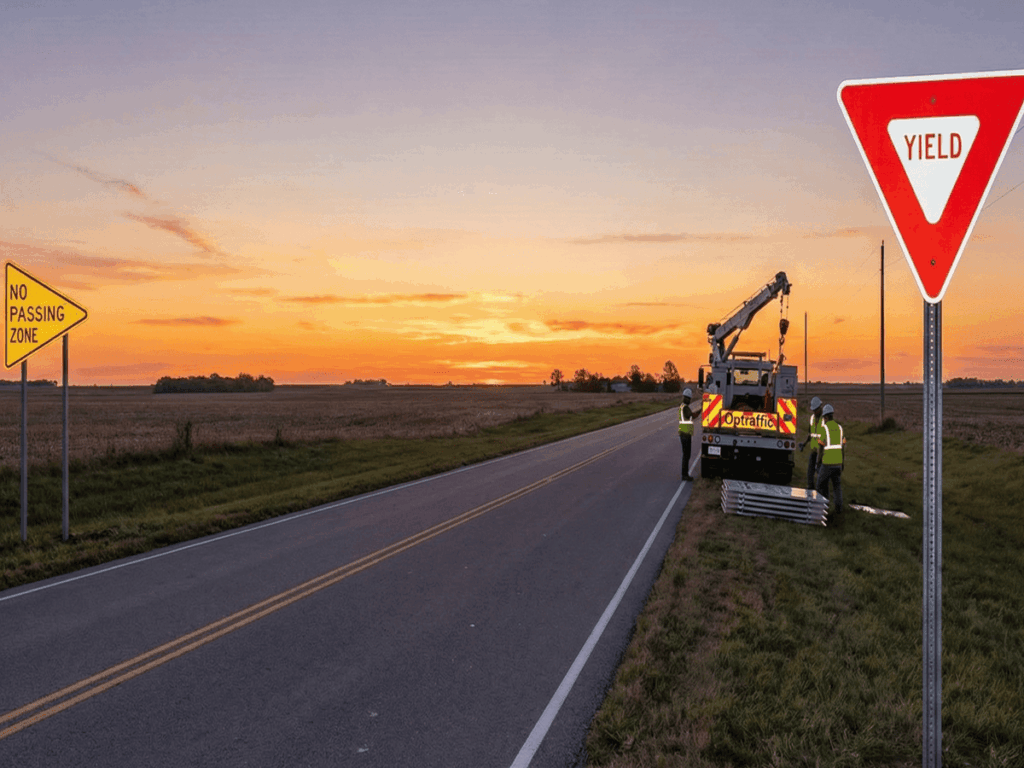

OPTsigns Verkehrskegel offer enhanced visibility and durability, designed to withstand the toughest job sites. Whether it’s bright orange or reflective for low-light conditions, OPTsigns cones ensure that your work zones are clearly marked and easily identifiable. Mit OPTsigns, you don’t just enhance safety—you create a well-organized, efficient workspace. Trust OPTsigns for reliable, high-quality traffic management solutions that keep your team and equipment secure.

Understanding Mobile Elevating Work Platforms (Mewps)

What Are Mobile Elevating Work Platforms (Mewps)?

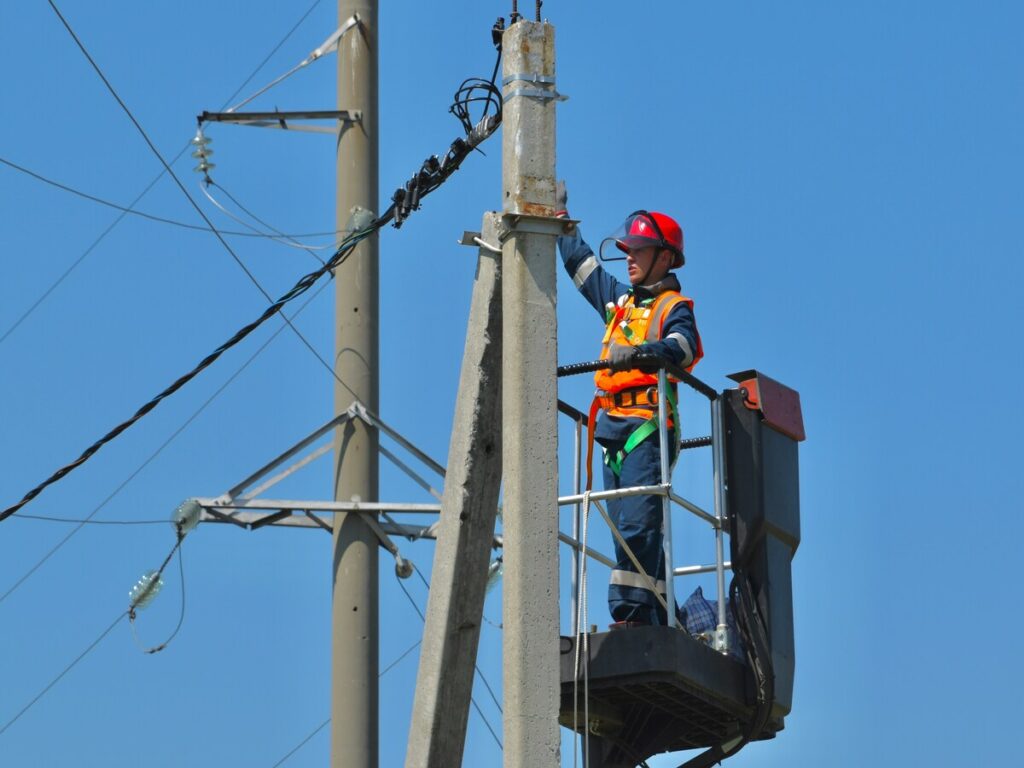

Mobile Elevating Work Platforms (Mewps) are specialized equipment designed to lift workers to elevated heights, providing them with safe access to high or hard-to-reach areas. These platforms are commonly used in industries like construction, Wartung, and warehousing, where tasks require workers to be elevated for tasks such as painting, electrical work, or building maintenance.

Mewps come in various forms, including scissor lifts, boom lifts, and vertical mast lifts, each tailored to specific needs and environments. They are mobile, meaning they can be easily moved around job sites, offering flexibility and convenience. Jedoch, like any heavy machinery, proper operation and safety measures are essential to prevent accidents and ensure the well-being of operators and surrounding workers.

Importance of Safety When Using MEWPs on Job Sites

The use of Mobile Elevating Work Platforms (Mewps) significantly enhances productivity on job sites, but they also come with inherent safety risks. Due to their height and mobility, MEWPs present dangers such as falling from heights, tip-overs, contact with overhead power lines, and collisions with other equipment or workers. These risks can lead to serious injuries or even fatalities, Sicherheit zu einer oberen Priorität machen.

Operators must undergo proper training and certification to operate MEWPs safely, and employers should conduct regular inspections to ensure the equipment is in good working order. Zusätzlich, job sites must implement safety protocols such as the use of fall protection systems, harnesses, and clearly marked work zones to keep workers out of harm’s way.

One of the most effective ways to reduce the risk of accidents is to create clear boundaries around the area where the MEWP is being used, ensuring both operators and bystanders are aware of the hazardous zone. This is where traffic cones become vital in maintaining safety on job sites.

The Role of Plastic Safety Cones in MEWP Work Zones

Establishing Exclusion Zones

Defining safe boundaries for MEWP operations

Plastic safety cones are essential for creating exclusion zones around mobile elevating work platforms. These zones define clear boundaries, ensuring that only authorized personnel enter areas where MEWP operations are underway. By marking the perimeter with cones, you can establish a visible barrier that separates workers from potential hazards. This approach minimizes the risk of accidents caused by unauthorized access or confusion about the work zone’s limits.

Cones also help you organize the workspace effectively. Zum Beispiel, you can use them to designate specific areas for equipment, Materialien, or vehicle parking. This organization reduces clutter and enhances overall safety. When you position cones strategically, they act as a visual guide, helping workers and operators stay within safe operating zones.

Preventing unauthorized access to hazardous areas

Traffic safety cones act as a deterrent to unauthorized entry into dangerous areas. Ihre leuchtenden Farben und reflektierenden Oberflächen machen sie gut sichtbar, sogar drin Bedingungen bei schlechten Lichtverhältnissen. This visibility ensures that pedestrians and vehicles recognize restricted zones and avoid entering them.

You can also use plastic traffic cones to create layered safety zones, such as advance warning areas and activity zones. These layers provide multiple opportunities to alert individuals before they approach hazardous areas. By combining plastic traffic cones with proper signage, you enhance the effectiveness of your exclusion zones and reduce the likelihood of accidents.

Managing Pedestrian and Vehicle Traffic

Directing traffic flow around MEWP sites

Effective traffic control is crucial when working with mobile elevating work platforms. Plastic safety cones help you manage the flow of both pedestrians and vehicles around the worksite. By placing plastic traffic cones in advance warning zones, you alert drivers to upcoming work areas, giving them time to adjust their speed or change lanes. Transition zones guide vehicles safely around the activity zone, ensuring that workers and equipment remain undisturbed.

For pedestrian traffic, plastic traffic cones can mark safe walkways or entry points, keeping individuals away from machinery and other hazards. Using color-coded plastic traffic cones, such as orange for construction and lime for pedestrian control, further improves traffic management by providing clear visual cues.

Enhancing visibility for workers and the public

Traffic cones enhance visibility for everyone near the worksite. Ihre leuchtenden Farben, such as orange and lime, stand out against most backgrounds, sie leicht zu erkennen machen. Proper placement ensures that workers can see the plastic traffic cones clearly, helping them stay within designated zones. For the public, plastic traffic cones act as a warning system, signaling the presence of a worksite and guiding them safely around it.

When you use plastic traffic cones with reflective strips, they remain visible even at night or in poor weather conditions. This added visibility reduces the risk of accidents, ensuring that both workers and bystanders stay safe. Durch Einbeziehen von Verkehrskegeln in Ihren Sicherheitsplan, you create a more secure environment for everyone involved.

Best Practices for Using Plastic Safety Cones with Mobile Elevating Work Platforms

Platzierungsstrategien

Positioning cones to maximize safety

Proper traffic cone placement is essential for ensuring safety during mobile elevating work platform operations. You should position plastic traffic cones where they are clearly visible to workers and bystanders. This visibility helps define the work zone and prevents accidental entry into unsafe areas. Following OSHA guidelines ensures effective traffic cone placement. Zum Beispiel, tapers should be long enough to provide a safe working space. The length depends on the width of the offset and the posted speed limit.

Adapting placement to different work environments

Different work environments require specific traffic cone placement strategies. You can adapt these strategies to suit the unique needs of each site:

- Advance Warning Zone: Use plastic construction cones to alert drivers about the upcoming work zone. The length of this zone should match the speed limit to provide adequate warning.

- Transition Zone: Place plastic construction cones to guide vehicles into a safe path, ensuring smooth merging and minimizing disruptions.

- Activity Zone: Clearly mark this area to direct vehicles away from workers and equipment. This step is crucial for maintaining safety in high-risk zones.

By tailoring traffic cone placement to the environment, you enhance the effectiveness of your traffic control plan.

Abstandsrichtlinien

Following OSHA recommendations

Spacing traffic cones correctly is just as important as their placement. OSHA recommends maintaining proper visibility of cones throughout the work zone. A temporary traffic control plan should outline the spacing requirements to ensure safety. Signs and instructions must accompany the cones to guide drivers and pedestrians effectively. Workers involved in traffic control need training to comply with OSHA -Standards.

Adjusting spacing based on site-specific needs

You should adjust cone spacing to match the specific conditions of your worksite. Zum Beispiel, in areas with higher speed limits, cones should be spaced farther apart to give drivers more time to react. Im Gegensatz, tighter spacing works better in low-speed zones or areas with heavy pedestrian traffic. Regularly inspect the work zone to ensure that the spacing remains consistent and effective. This proactive approach helps maintain a safe and organized environment.

Types and Applications of Plastic Safety Cones

Arten von Leitkegeln

Standard cones vs. Hochleistungskegel

Traffic cones come in two main types: standard and heavy-duty. Standard cones are lightweight and easy to transport, making them ideal for temporary setups like short-term construction or quick traffic control tasks. Hochleistungskegel, auf der anderen Seite, are designed for durability. They withstand harsh weather conditions and resist tipping over in high-wind areas or busy work zones. These plastic construction cones are perfect for long-term projects or environments with heavy vehicle movement.

When working with Mobile Elevating Work Platforms (Mewps), heavy-duty cones often provide better stability. Their robust design ensures they remain in place, auch unter schwierigen Bedingungen. Standardkegel, Jedoch, can still be effective in low-risk areas or indoor environments where stability is less of a concern.

Choosing the right type for MEWP operations

Selecting the right cone type depends on your specific MEWP operation. For outdoor construction sites, heavy-duty cones offer the durability needed to handle rough conditions. For indoor tasks, standard cones may suffice, especially in areas with minimal wind or traffic. Proper placement of plastic construction cones ensures workers clearly see the designated work zones, reducing confusion and enhancing safety features.

Color Coding and Its Importance

Common traffic cone colors and their meanings

Traffic cone colors serve specific purposes, helping you communicate safety messages effectively. Here’s a quick guide to common colors and their applications:

| Farbe | Anwendung |

|---|---|

| Orange | Baustellen, Verkehrskontrolle |

| Lime | Entryways, pedestrian control |

| Blau | Accessible parking, overhead wire hazard |

| Weiß | Valet parking, advertising displays |

| Rot | Workplace hazards (Verschüttungen, blinde Flecken, usw.) |

| Gelb | Indoor safety hazards |

| Rosa | Children’s events |

Each color provides a visual cue, ensuring that workers and bystanders understand the purpose of the plastic construction cones at a glance. Zum Beispiel, orange cones are widely used for traffic control, while lime cones are ideal for guiding pedestrians in entryways or warehouses.

Selecting colors for specific safety applications

Choosing the right color for your MEWP work zone enhances safety features and improves traffic control. Für Baustellen, orange cones are the standard choice. Lime cones work well for pedestrian-heavy areas, while blue cones warn of overhead wire hazards. Red cones highlight workplace dangers like spills or blind spots.

By matching cone colors to their intended application, you create a safer and more organized work environment. This approach ensures that everyone near the site understands the safety measures in place, Reduzierung des Unfallrisikos.

Training and Compliance for MEWP Safety

Educating Workers on Traffic Cone Usage

Training programs for proper cone placement

Proper training ensures that workers use traffic cones effectively during a mewp operation. A well-structured program focuses on key components to maximize safety and efficiency:

- Ensure cones are visible to workers and pedestrians to define work zones clearly.

- Follow OSHA guidelines for cone placement to meet safety standards.

- Use accurate taper measurements to create well-defined work zones.

Training should also emphasize the importance of maintaining consistency in cone placement. Workers must understand how to adapt cone positioning based on site-specific conditions, such as speed limits or pedestrian activity. This knowledge helps create a safer environment for everyone involved.

Understanding MEWP-specific safety protocols

Workers must familiarize themselves with safety protocols specific to aerial work platform operations. Dazu gehören:

- Training on tasks involving large equipment to reduce risks.

- Establishing advance warning zones to alert drivers of work areas.

- Using transition zones to guide vehicles safely around the site.

- Clearly marking activity zones to keep vehicles away from workers and machinery.

- Setting up termination zones to direct traffic back to normal paths.

These protocols align with OSHA traffic control guidelines, which aim to create a secure safety zone for workers and ensure smooth traffic flow. By following these measures, you can prevent accidents and maintain an organized worksite.

Sicherstellung der Einhaltung von Sicherheitsstandards

Adhering to OSHA and industry regulations

Compliance with OSHA and industry regulations is essential for maintaining safety during MEWP operations. OSHA emphasizes the use of traffic control measures, such as plastic construction cones, to protect workers and the public. Temporary traffic control zones must guide road users safely around work areas, especially during highway construction or maintenance.

You should also secure the area with warning plastic construction cones or hazard tape during aerial work platform operations. These measures ensure that both workers and bystanders remain safe throughout the project.

Conducting regular safety audits and inspections

Regular audits and inspections are critical for sustaining a strong safety culture. These evaluations help identify potential hazards and ensure compliance with OSHA standards. Inspectors should assess the placement and spacing of plastic safety cones, the condition of fall protection systems, and the effectiveness of the traffic management plan.

Frequent inspections also ensure that personal protective equipment and fall protection systems are in good condition. By addressing issues promptly, you can maintain a safe and efficient work environment.

Traffic cones play a critical role in maintaining safety during MEWP operations. You ensure visibility and protection in work zones by placing plastic safety cones correctly. Following OSHA guidelines helps you meet safety standards and avoid risks. Using different cone colors, like orange for construction or red for hazards, communicates clear safety messages.

Tipp: Consistent training and regular audits strengthen your safety measures.

Fostering a safety-first mindset creates a secure environment for everyone. When you prioritize proper placement, Ausbildung, und Compliance, you build a culture that values safety and efficiency.