Traffic sign size is the main thing that affects which material and mounting options are used in Australia. Bigger signs let drivers see important information from farther away. This helps keep people safe and makes sure signs follow Australian standards. The table below shows how traffic sign size changes how far drivers can read them:

| Zeichengröße (mm) | Ungefähre lesbare Entfernung (M) |

|---|---|

| 600 | 60 |

| 900 | 100 |

| 1200 | 150 |

Australian standards say signs must be a certain size for each speed zone. This is to make sure drivers can see them, especially in work zones and road work areas. Wenn die Schilder zu klein sind, they might not be safe. People may not follow the rules, and there could be legal problems. The right sign size helps traffic management and road work warnings reach drivers on time. This supports the rules and keeps everyone safe. Räte, Auftragnehmer, and people who manage traffic use these standards to make work zones safe for all road users.

To learn how to choose the correct sign size for your project and stay compliant across different speed zones, Lesen Sie unseren vollständigen Leitfaden: Verkehrszeichengrößenstandards in Australien: Ein vollständiger Leitfaden.

Traffic Sign Size and Material Choice

Small Signs: Materials and Thickness

Small construction traffic signs are important in work zones. These signs are usually less than 600 mm breit. Because they are small, they do not catch much wind. They are also lighter than bigger signs. Das heisst lighter materials can be used. Aluminium is the most popular material for these traffic signs in Australia. Es ist leicht, rostet nicht, und hält lange. Councils and contractors often pick aluminium panels with reflective sheeting. This makes the signs easy to see and meets Australian standards.

The thickness of small signs depends on where they go:

- 0.040-inch aluminium is good for inside or calm outdoor places.

- 0.080-inch aluminium works for quiet or less busy outdoor spots.

- 0.125-inch aluminium is best for busy or rough weather areas.

Notiz: Thicker aluminium, from 0.063-inch to 0.125-inch, is better for outside. It helps the sign stand up to wind and bad weather.

Schutzbeschichtungen, Wie Pulverbeschichtung, Helfen Sie den Schildern, länger zu halten. This is important in tough weather. Reflective materials and reflective sheeting make signs brighter. This helps people see them at night or when it is raining. Councils might have their own rules about thickness or reflectivity. Always check local rules before picking materials.

Medium Signs: Materialoptionen

Medium-sized construction traffic signs are between 600 mm und 900 mm. These signs need stronger materials and better mounting. They face more wind and must stay steady in busy places. Aluminium is still the main choice, but it is thicker, um 2.0 mm. For signs near 900 mm, 2.5 mm zu 3.0 mm aluminium or composite panels are used.

Verbundplatten, like aluminium composite material (ACM), are strong and not too heavy. They do not bend easily and give a flat surface for reflective sheeting. Polycarbonate is another choice for lightweight signs. It is good if the sign might get hit. But polycarbonate does not last as long in sunlight because of UV rays.

Plastikzeichen, such as PVC or polypropylene, are only for low-risk places. These are indoor areas or private land with signs under 600 mm. Plastic signs are not as strong or bright as aluminium or composite panels.

Medium signs must use reflective materials to be seen well. Reflektierende Bleche, wie Klasse 1W oder Klasse 3, helps drivers see the signs from far away. Councils may ask for certain reflective grades or materials for these signs.

Große Zeichen: Reinforcement and Substrates

Large construction traffic signs are usually over 900 mm breit. These signs need special materials and extra support. They face the most wind and must stay steady in all weather. Aluminium is still used, but it is thicker, um 2.5 mm oder sogar 3.0 mm. For very big signs, engineers might use composite panels or steel, especially in cities or places with lots of damage.

Extra support is needed for signs wider than 1200 mm. Common ways to add support include:

- Central ribs or two horizontal stiffeners

- Frames around the whole sign

- Back stiffeners and edge flanges

- Diagonal braces and wind-spread load plates

Tipp: Galvanised steel posts are very strong and do not rust. They are good for large signs in windy or coastal places. Aluminium posts are lighter and do not rust, so they are good for wet areas.

Large signs use different bracket systems, like U-bolts and channel-style attachments. Some use adjustable swivel kits. These keep the sign steady and in the right place when it is windy. Councils and states may have their own rules for large signs. This is important in fast or windy areas. Always check local rules and Australian standards before picking materials or supports.

| Zeichengröße (mm) | Empfohlenes Material | Typische Dicke (mm) | Reinforcement Needed? |

|---|---|---|---|

| <600 | Aluminium | 1.2–1.6 | NEIN |

| 600–900 | Aluminium/Composite | 2.0–3.0 | Manchmal |

| >900 | Aluminium/Composite/Steel | 2.5–3.0+ | Ja |

Reflectivity is very important for all large signs. High-grade reflective sheeting makes sure signs can be seen at night or in bad weather. Reflective materials must meet Australian rules.

Councils and states may have their own rules for Materialien für Verkehrszeichen, Dicke, and support. Always check local rules before buying or putting up signs.

Bei OPTRAFFIC, we understand the importance of meeting both national and local requirements. Our team works closely with road authorities to deliver Verkehrszeichen zum Verkauf that comply with each region’s specifications, ensuring your projects stay on track and fully compliant from the start.

Mounting Options by Sign Size

Small Signs: Posts and Brackets

Small construction traffic signs are less than 600 mm breit. These signs need simple but strong mounting systems. Councils and contractors often use round or square posts. Adjustable brackets help set the right angle and height. Dadurch ist das Schild gut erkennbar. Modular brackets are common in busy cities. They make repairs and maintenance quick.

The materials for posts and brackets depend on the area:

- Galvanised steel posts are good for cities and inland places. Sie rosten nicht so leicht.

- Marine-grade aluminium posts are best for coastal areas. Salt air can cause rust, so these posts last longer.

- Stainless steel posts work well in tough places. These are used in northern Australia where storms and pollution happen a lot.

Installers use stainless steel hose clamps and pole kits. These hold signs tight without drilling holes in the posts. Brackets have UV-resistant and corrosion-resistant coatings. This helps them last in Australian weather. Cleaning and checking brackets often keeps them strong. This also makes sure the sign stays in place. All mounting systems must follow Australian standards. These include AS/NZS 1906 und als/nzs 1170.2. This keeps signs safe and strong in the wind.

Medium Signs: Reinforced Mounts

Medium construction traffic signs are 600 mm zu 900 mm breit. These signs face more wind and need stronger mounts. U-channel posts and square tube posts are often used. These posts give extra support and keep signs steady. This is important in busy or stormy places.

Reinforced mounts often have:

- Multi-point brackets that match the sign’s holes.

- Post clamps that hold the sign tight.

- Load-spread washers and spacers to spread the weight.

Installers must follow rules for where to put the posts. These rules are in Australian standards. The right height and space between posts help drivers see the signs. Councils may ask for stronger mounts in risky places. These include school zones or busy crossings. Checking mounts often stops them from getting loose or broken. This keeps the signs working and following the rules.

Große Zeichen: Multi-Post and Gantry Systems

Large construction traffic signs are over 900 mm breit. These signs need special mounting systems. Multi-post and gantry systems give strong support. Engineers design these systems to handle strong winds and bad weather.

The table below shows important engineering needs for these systems in Australia:

| Engineering Aspect | Spezifikationsdetails |

|---|---|

| Materialien | Steel grades: Q235, Q345, S235, S355, SS400 |

| Minimum Yield Strength | ≥235 N/mm² for Q235, S235, SS400; ≥345 N/mm² for Q345, S355, Gr 50 |

| Stabhöhe | 3 Zu 15 Meter |

| Wall Thickness | 6 Zu 8 mm |

| Pole Shapes | Polygonal, Runden, Achteckig, Taper round, Round conical, Taper Square, Quadrat |

| Oberflächenbehandlung | Hot dip galvanisation (80-100 µm), Pulverbeschichtung, rough pole finish |

| Temperaturbereich | -35 °C to +65 ° C |

| Windwiderstand | Designed for wind speeds from 120 km/h up to 180 km/h or per client design |

| Base Plate Mounting | Quadrat, achteckig, or round base plates with slotted holes for anchor bolts, customisable dimensions |

| Ground Mounting | Burial length underground customisable per client requirements |

| Qualitätskontrolle | ISO9001-2008 standard |

| Galvanisation Standard | IN 1461 |

Multi-post systems use two or more posts for wide signs. This stops the sign from bending or falling. Gantry systems are used over highways. They use steel frames to hold big signs above the road. These systems need deep concrete bases to stay steady. Engineers must check wind zones and council rules before putting up these signs.

Mounting Hardware and Hole Layouts

The hardware and hole layout depend on the sign’s size and type. Small signs use two or four holes for easy mounting. Medium signs need more holes to fit U-channel or T-posts. Large signs need custom holes for square posts, RHS brackets, or gantry frames.

Installers pick hardware based on the sign’s weight and where it goes. Flat signs use cap-mount or two-way brackets in calm places. Heavier extruded signs need deep channel or clamp systems. In busy or risky places, anti-vandal hardware is needed. Tufnut security nuts, break away tamperproof nuts, and tri-groove anti-theft nuts stop theft and damage. These nuts keep signs safe for a long time.

Tipp: Installers should always check if the hardware matches the sign’s size and weight. The right hardware lowers repair costs and keeps signs safe and easy to see.

Australian standards set the height and space for all construction traffic signs. Signs must be high enough for drivers to see but low enough for repairs. Good placement helps everyone see the signs and keeps roads safe.

Australian Standards and Compliance

Key Standards for Traffic Signs

Australian standards have clear rules for traffic signs in work zones. Die Hauptstandards sind ALS 1743, ALS 1742, Und Als/nzs 1170.2. These standards help decide the size, Material, and mounting of signs. ALS 1743 tells how road signs should be made and what they are made from. ALS 1742 explains how to use signs in different traffic situations, like work zones. Als/nzs 1170.2 is about wind and keeping signs safe and strong. Signs must follow these standards to keep people safe and follow the law. Councils and contractors use these rules to pick the right materials and mounting for each sign. Following the standards helps signs stay easy to see and strong in all weather.

Wind Load and Structural Safety

Wind load is very important for sign safety. Signs in Australia face different wind areas, from calm places to windy coasts. Als/nzs 1170.2 gives the rules for working out wind load. The wind load depends on the sign’s size, Höhe, and local wind speed. The formula for wind load uses things like air density, wind force, und Zeichengröße. Zum Beispiel, the formula F = γO γQ (1/2 ρ C v²) W H helps engineers find the force on a sign. Signs in windy places must handle wind speeds of at least 22 MS. Engineers use computers to test sign strength and design holes to lower wind pressure. These steps help signs stay safe and not break in storms. Große Zeichen, especially in risky work zones, need a certificate to show they are strong enough.

Council and State Variations

Local councils and states can have extra rules for signs in work zones. These rules change where signs go, what they are made from, and how they are put up. Project planners must check the site for things like ground level, Biegungen, and nearby pipes or wires. They also need to follow local product lists and get approval for materials. Teams must use the right tightness on bolts and check signs after putting them up. Some councils want signs covered or uncovered at certain times to stop confusion. Work zone plans often have extra safety steps, like traffic controllers, lower speed limits, and special paths for people walking. Local rules may also change the colours and symbols on signs. Good teamwork between designers, Ingenieure, and councils helps everyone follow the rules and keeps work zones safe.

Visibility and Safety Considerations

Sign Size and Readability

Sign size is very important for safety and visibility. Bigger construction traffic signs help drivers read messages from far away. This is very important in work zones. Australian rules say portable variable message signs on fast roads need letters at least 200 mm groß. This gives drivers enough time to see warning signs and react safely. The table below shows how the size of the digits changes how far people can see them and how they are used:

| Zeichengröße (Digit Height) | Recommended Use Case | Effective Visibility Range | Approach Speed Context |

|---|---|---|---|

| 15-inch digits | Städtische Gebiete, Schulzonen, Wohnstraßen | Bis zu 400 Füße | Lower speed, shorter viewing distances |

| 18-inch digits | Autobahnen, Schnellstraßen, Hochgeschwindigkeitsstraßen | Über 600 Füße | Higher speed, long-distance visibility |

Groß, clear signs make messages easy to understand. Good sign placement helps drivers see construction traffic signs in all work zones. This helps drivers make safe choices.

Mounting for Maximum Visibility

Mounting construction traffic signs the right way is very important. Signs need to be high enough so drivers can see them clearly. This is extra important in hilly or blocked areas. In flat places, normal mounting heights work well. Signs must be above things like parked cars or fog. Reflective materials and good placement help signs stand out at night or in bad weather. Checking signs often keeps them easy to see and working well.

- Putting signs higher helps in hilly places.

- The right height keeps signs above snow, Nebel, or cars.

- Reflective sheeting and the right angle help at night.

- Die Überprüfung der Schilder sorgt oft dafür, dass sie gut funktionieren.

Australian rules say signs must be a certain height. Im Land, Schilder müssen mindestens sein 1.5 Meter über dem Boden. An Orten, an denen Menschen gehen, Schilder müssen mindestens sein 2.1 Meter hoch. Signs should face the road and tilt a little, bis zu 10 Grad, for best reflection.

Safety Risks of Incorrect Sizing

Signs that are too small or not put up right are dangerous. Small or badly placed construction traffic signs are hard to see. Drivers might miss warnings about road work ahead. This can cause accidents. Signs too close to dangers do not give drivers enough time to react. Dies macht Abstürze wahrscheinlicher. Old or dull signs are hard to see at night, which is unsafe for everyone.

Notiz: Strong mounting and checking signs often stop them from falling or moving. This keeps signs working well for traffic management and safety in work zones.

Putting signs in the right place, using the right traffic sign size, and making them bright keeps drivers safe. Following Australian rules for height and direction makes sure construction traffic signs are clear and easy to see in all conditions.

Cost and Maintenance Factors

Material and Installation Costs

The size and material of a sign affect its price. Größere Schilder benötigen mehr Material, Sie kosten also mehr. Kleinere Zeichen, unter 1 square metre, sind günstiger. They use less aluminium or plastic. Here are some important things to know about costs:

- Aluminium is used most for road construction traffic signs. It is strong and stands up to bad weather.

- Colourbond steel is tougher and lasts longer in busy places. It usually costs more than aluminium.

- Plastic materials like polypropylene are the cheapest. They are best for temporary construction traffic signs because they do not last long.

- The cost to put up a sign depends on the mounting system. Strong posts and tight fixings stop signs from falling or turning in the wind.

- Electronic road construction traffic signs need wiring and solar panels. This makes them more expensive to install.

- Durch den gleichzeitigen Kauf mehrerer Schilder kann jedes einzelne günstiger werden. Custom designs cost more because they need special work.

Signs must be put up the right way to follow Australian rules. This means the right height, Winkel, and place. Doing this keeps construction traffic signs and road construction traffic signs safe and easy to see.

Wartung und Austausch

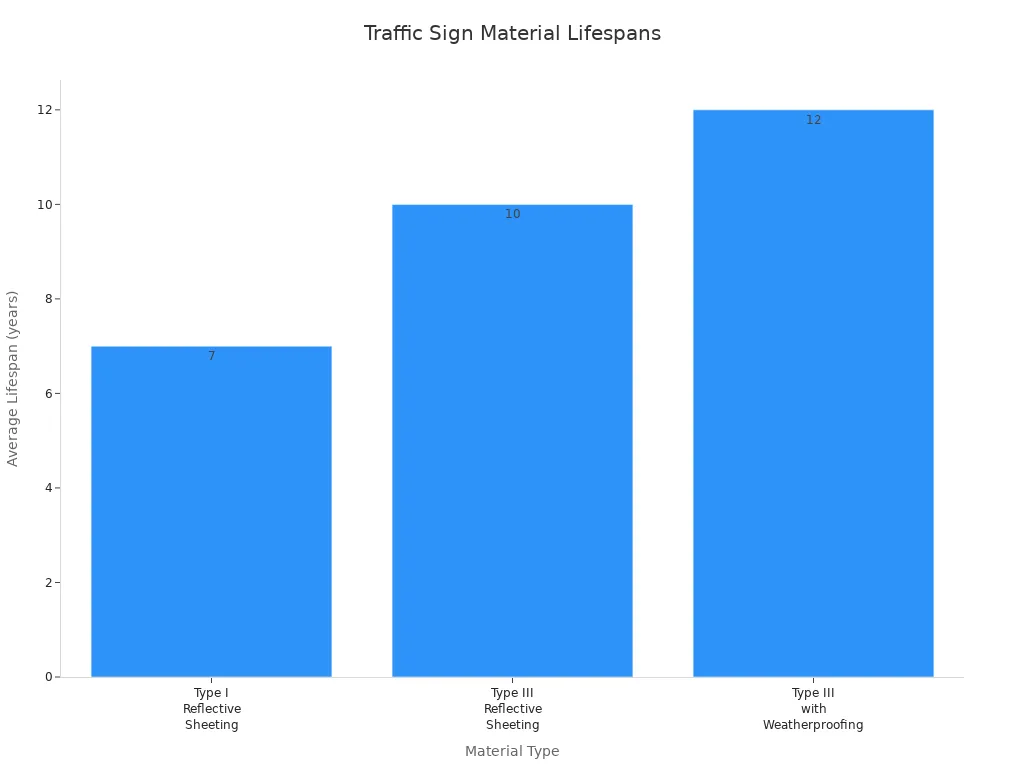

Looking after construction traffic signs keeps them clear and easy to read. Different materials last for different times in Australia. The table below shows how long each type of sign material usually lasts:

| Materialtyp | Average Lifespan in Australian Conditions |

|---|---|

| Type I Reflective Sheeting | Um 7 Jahre |

| Type III Reflective Sheeting | Um 10 Jahre |

| Type III with Weatherproofing | Bis zu 12 Jahre |

Das Reinigen und Überprüfen von Schildern hilft ihnen oft, länger zu dauern. Weekly cleaning gets rid of dirt and finds damage. Monthly checks look at the sign’s bolts and posts. Einmal im Jahr, experts check the whole sign and how well it reflects light. Replace signs if they fade, schälen, oder brechen. Weatherproof coatings and good reflective materials help construction traffic signs last longer, selbst bei rauem australischem Wetter.

Tipp: Using digital records helps councils and contractors know when to fix or change road construction traffic signs.

The size of a traffic sign affects what materials and mounts are used. Picking the right size helps signs follow the rules and keeps drivers safe. Teams that talk early and check their work make fewer mistakes. This helps traffic jobs finish on time. Checking signs often and following Australian rules keeps them easy to see and safe. Räte, Arbeiter, and owners can do these things:

- Always put safety and following the rules first for all traffic signs.

- Check traffic signs every month for damage or loose parts.

- Choose the best materials for each place to keep signs clear and follow the rules.

- Write down when you put up or fix any traffic sign.

Planning well and working together helps every traffic sign follow the rules, be easy to see, und für sichere Straßen sorgen.

FAQ

What materials work best for large construction signs?

Large construction signs use aluminium and composite panels. These materials are strong and do not rust. Manchmal, engineers add steel for more support in windy places. Councils pick these materials to follow Australian standards and keep people safe.

How often should teams inspect construction signs?

Teams need to check signs every month. Checking often helps find damage or fading early. Fixing problems quickly keeps signs easy to see and safe for everyone. Councils say to write down each inspection.

Do all signs need reflective sheeting?

Most traffic signs must have reflektierende Bleche. Dies hilft den Fahrern, nachts oder bei schlechtem Wetter Schilder zu sehen. Australian standards say how much reflectivity is needed for each sign and place.

Können Plastikschilder im Freien verwendet werden?

Plastic signs are best for inside or private land. Draußen, they can fade or break fast. Councils like aluminium or composite for outdoor signs because they last longer and follow safety rules.

Who decides the correct traffic sign size?

Australian standards and councils choose the right traffic sign size. They look at road speed, wie einfach Zeichen sind zu sehen, und Sicherheit. Following these rules helps keep drivers and workers safe.