Möglicherweise ist es Ihnen nicht bewusst, Aber Verkehrssicherheitskegel haben eine faszinierende Geschichte. Sie begannen als einfache Holzmarker und entwickelten sich zu den modernen Kunststoffversionen, die Sie heute sehen. Bei dieser Transformation ging es nicht nur um den Materialwechsel; Es ging darum, die Sicherheit zu erhöhen und die Umweltbelastung zu verringern. Frühen Holzkegeln mangelte es an Haltbarkeit und Sichtbarkeit. Im Laufe der Zeit, Innovationen wie reflektierende Materialien Und Solarbetriebene LED-Leuchten ihre Wirksamkeit verbessert. Heute, Verkehrsleitkegel sind nicht nur besser sichtbar, sondern auch intelligenter, Einige sind sogar mit Sensoren ausgestattet, um Verkehrsdaten in Echtzeit bereitzustellen. Diese Entwicklung unterstreicht die Bedeutung wesentlicher Veränderungen im Verkehrsmanagement.

OPTsigns Bietet hochwertige, moderne Leitkegel aus Kunststoff, die den heutigen Sicherheitsstandards entsprechen.

Die Geburt der Verkehrsleitkegel

Frühzeitige Anforderungen an das Verkehrsmanagement

Anfang des 20. Jahrhunderts, Die Straßen begannen rasch zu wachsen. Je mehr Fahrzeuge auf die Straße kommen, Die Notwendigkeit eines effektiven Verkehrsmanagements wurde deutlich. Sie fragen sich vielleicht, wie die Menschen vor der Erfindung der Leitkegel den Verkehr verwaltet haben. Anfänglich, Sie nutzten Holzbarrieren und Fahnen, um Fahrzeuge zu lenken. Jedoch, Diesen Methoden mangelte es an Flexibilität und Transparenz, Besonders nachts oder bei schlechten Wetterbedingungen.

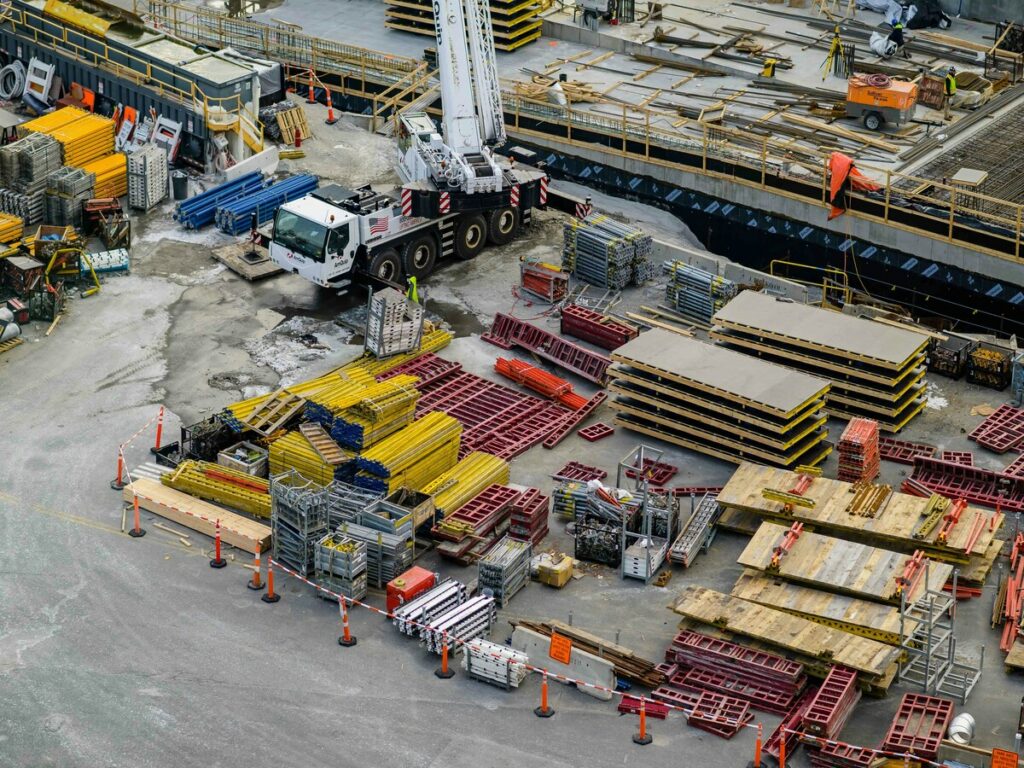

Die wachsende Zahl von Autos auf der Straße machte deutlich, dass eine effizientere Lösung erforderlich ist. Verkehrsleitkegel erwiesen sich als entscheidendes Hilfsmittel zur Steuerung des Verkehrsflusses und zur Gewährleistung der Sicherheit. Sie dienten mehreren Zwecken, Beispielsweise können Fahrer von Baustellen weggeleitet und auf Änderungen der Straßenverhältnisse aufmerksam gemacht werden. Diese Innovation markierte einen bedeutenden Fortschritt im Verkehrsmanagement.

Erfindung des ersten Leitkegels

Die Erfindung des ersten Leitkegels in den 1940er Jahren revolutionierte die Verkehrssicherheit. Charles d. Scanlon, ein Maler für das Los Angeles Streets Department, erfand die erste Mulde, konischer Marker. His creation aimed to prevent cars from driving over freshly painted lines. This simple yet effective design quickly gained popularity due to its practicality.

Traffic cones became one of America’s most important inventions. They provided a clear and visible notification to drivers, indicating which lanes or roadways to avoid. The introduction of traffic cones addressed the growing need for a reliable safety device as road networks expanded. This invention laid the foundation for the modern traffic safety cones we see today.

Wooden Cones: The Initial Solution

Materials and Design of Wooden Cones

In the early days of traffic management, wooden cones served as the primary solution for directing vehicles. You might find it interesting that these traffic safety cones were crafted from solid wood, was eine robuste, aber etwas unflexible Struktur lieferte. Das Design war schlicht, Es zeichnet sich durch eine konische Form aus, die für Autofahrer leicht zu erkennen ist. Jedoch, Das Gewicht des Holzes machte es schwierig, diese Verkehrsleitkegel zu bewegen und einzusetzen. Trotz ihrer Einschränkungen, Holzleitkegel spielten in der Anfangsphase der Verkehrssicherheit eine entscheidende Rolle.

Die Verwendung von Holz in diesen Kegeln machte sie anfällig für Witterungseinflüsse. Durch Regen und Feuchtigkeit kann das Holz mit der Zeit aufquellen oder verfaulen, Reduzierung ihrer Wirksamkeit. Zusätzlich, Das Fehlen reflektierender Materialien an diesen frühen Kegeln machte es schwierig, sie nachts oder bei schlechten Sichtverhältnissen zu erkennen. Dieses Design, obwohl es für seine Zeit innovativ war, betonte den Bedarf an haltbareren und sichtbareren Materialien im Verkehrsmanagement.

Einschränkungen und Herausforderungen von Holzkegeln

Hölzerne Verkehrskegel standen vor mehreren Herausforderungen, die ihre Wirksamkeit einschränkten. Erste, Ihr Gewicht machte es schwierig, sie schnell zu transportieren und zu positionieren. Sie können sich vorstellen, wie umständlich es wäre, diese schweren Gegenstände über stark befahrene Straßen zu bewegen. Diese mangelnde Tragbarkeit verhinderte ihren weit verbreiteten Einsatz in dynamischen Verkehrssituationen.

Darüber hinaus, Den Holzkegeln fehlte die erforderliche Flexibilität, um den Stößen von Fahrzeugen standzuhalten. Wenn geschlagen, sie könnten brechen oder splittern, zusätzliche Gefahren im Straßenverkehr darstellen. Diese Steifigkeit bedeutete auch, dass sie nach dem Zusammendrücken nicht in ihre ursprüngliche Form zurückkehren konnten, im Gegensatz zu modernen Leitkegeln aus flexiblen Materialien.

Eine weitere große Herausforderung stellte die Sicht dar. Ohne reflektierende Oberflächen, Holzkegel waren bei schlechten Lichtverhältnissen schwer zu erkennen, Erhöhen des Unfällerisikos. Diese Einschränkungen unterstrichen den Bedarf an Innovationen bei der Gestaltung von Leitkegeln, ebnet den Weg für die Entwicklung fortschrittlicherer Materialien wie Gummi und Kunststoff.

Übergang zu Gummi und Metall

Einführung von Gummikegeln

Es könnte für Sie interessant sein, dass die Einführung von Gummikegeln einen bedeutenden Fortschritt im Verkehrsmanagement darstellte. In the early 1940s, Charles d. Scanlon entwickelte den ersten Verkehrskegel aus Gummi. Diese Innovation beseitigte viele der Einschränkungen, die Holzkegel mit sich bringen. Gummikegel boten Flexibilität und Haltbarkeit, Dadurch sind sie widerstandsfähiger gegen Stöße von Fahrzeugen. Als ein Auto gegen einen Gummikegel prallte, es würde sich biegen und in seine ursprüngliche Form zurückkehren, Dadurch wird das Risiko einer Beschädigung des Kegels und des Fahrzeugs verringert.

Gummikegel verbesserten zudem die Sicht. Die Hersteller begannen, leuchtende Farben und reflektierende Materialien zu integrieren, Verbesserung ihrer Wirksamkeit bei schlechten Lichtverhältnissen. Durch diese Änderung wurden Unfälle deutlich reduziert und die Verkehrssicherheit verbessert. Die Anpassungsfähigkeit von Gummikegeln machte sie viele Jahre lang zur bevorzugten Wahl, die Voraussetzungen für weitere Innovationen im Leitkegeldesign schaffen.

Verwendung von Metall in Verkehrskegeln

Leitkegel aus Metall erwiesen sich als eine weitere Lösung für die Herausforderungen früherer Konstruktionen. Sie fragen sich vielleicht, warum Metall für Verkehrskegel in Betracht gezogen wurde. Metallkegel boten eine robuste und langlebige Option, insbesondere in Gebieten mit hohem Verkehrsaufkommen. Sie konnten rauen Wetterbedingungen und wiederholten Stößen standhalten, ohne ihre Form zu verlieren.

Jedoch, Metallkegel hatten ihre Nachteile. Ihr Gewicht machte es schwierig, sie schnell zu transportieren und einzusetzen. Zusätzlich, Bei einem Aufprall bestand die Gefahr einer Fahrzeugbeschädigung. Trotz dieser Herausforderungen, Metallkegel spielten eine entscheidende Rolle bei der Entwicklung von Verkehrsmanagementinstrumenten. Sie betonten den Bedarf an Materialien, die Haltbarkeit mit Flexibilität verbinden, Wegbereiter für die Entwicklung moderner Leitkegel.

Der Übergang zu Gummi- und Metallkegeln markierte einen entscheidenden Moment in der Geschichte des Verkehrsmanagements. Diese Innovationen beseitigten viele der Einschränkungen von Holzkegeln und legten den Grundstein für die Entwicklung fortschrittlicherer Materialien. Wie Sie sehen können, Die Weiterentwicklung der Verkehrsleitkegel spiegelt das ständige Streben nach sichereren und effizienteren Straßenmanagementlösungen wider.

Der Aufstieg der Plastikkegel

Entwicklung von Kunststoffmaterialien

Die Entwicklung von Kunststoffmaterialien markierte einen bedeutenden Wendepunkt in der Entwicklung von Verkehrskegeln. Es könnte Sie interessieren, dass die Einführung von Plastik revolutionierte in den 1950er Jahren das Design und die Funktionalität dieser wichtigen Verkehrssicherheitswerkzeuge. Hersteller begannen mit der Verwendung Polyvinylchlorid (PVC), ein haltbarer und flexibler Thermoplast, Verkehrskegel zu erstellen. Dieses Material bot mehrere Vorteile gegenüber früheren Materialien wie Holz und Gummi.

Plastikverkehrskegel werden typischerweise durch einen Prozess namens Spritzguss hergestellt. Diese Methode ermöglicht die Erstellung einer nahtlosen, konische Form, die sowohl leicht als auch robust ist. Durch die Verwendung von PVC wird sichergestellt, dass die PVC-Kegel auch nach dem Zusammendrücken oder Überfahren ihre Form behalten. Diese Widerstandsfähigkeit macht sie ideal für verschiedene Umgebungsbedingungen, Von der sengenden Hitze bis hin zum Einfrieren von Kälte.

Darüber hinaus, die leuchtenden Farben von Plastikkegeln, oft in Orangetönen oder fluoreszierendem Limettengrün, erhöhen ihre Sichtbarkeit. Manufacturers also incorporate reflective materials or bands to improve their effectiveness in low-light conditions. These innovations have made plastic cones a staple in traffic management, providing a reliable and cost-effective solution for road safety.

Advantages of Plastic Over Previous Materials

Plastic traffic cones offer numerous advantages over their wooden and rubber predecessors. First and foremost, their lightweight nature makes them easy to transport and deploy. You can stack them efficiently, saving space and making them convenient for storage and transportation. This portability is crucial for quick deployment in dynamic traffic situations.

Another significant advantage is their durability. Plastic traffic cones withstand harsh weather conditions and repeated impacts without losing their shape. Unlike wooden cones, sie verrotten und splittern nicht, and unlike metal cones, Es besteht keine Gefahr, dass Fahrzeuge beim Aufprall beschädigt werden. Diese Haltbarkeit sorgt für eine längere Lebensdauer, sie zu einer kostengünstigen Wahl für das Verkehrsmanagement machen.

Verkehrsleitkegel aus Kunststoff zeichnen sich auch durch ihre Sichtbarkeit aus. Durch die leuchtenden Farben und reflektierenden Streifen sind sie für Autofahrer und Fußgänger gut sichtbar, Reduzierung des Unfallrisikos. Diese verbesserte Sichtbarkeit ist besonders bei schlechten Lichtverhältnissen wichtig, wo traditionelle Zapfen vielleicht unbemerkt bleiben.

OPTsigns bietet eine große Auswahl an hochwertigen Verkehrskegel aus Kunststoff Entwickelt für maximale Haltbarkeit und Sichtbarkeit.

Sicherheitsverbesserungen durch wesentliche Änderungen

Verbesserte Sichtbarkeit und Haltbarkeit

Sie werden vielleicht bemerken, dass moderne Verkehrsleitkegel deutlich auf der Straße hervorstechen. Diese Sichtbarkeit resultiert aus Fortschritten bei Materialien und Design. Hersteller verwenden leuchtende Farben wie Orange und fluoreszierendes Limonengrün, um Ihre Aufmerksamkeit zu erregen. Reflektierende Bänder erhöhen die Sichtbarkeit bei Nacht oder schlechtem Wetter. Diese Funktionen stellen sicher, dass Autofahrer und Fußgänger Verkehrskegel leicht erkennen können, Reduzierung des Unfallrisikos.

Auch für die Sicherheit von Fußgängern spielt die Haltbarkeit eine entscheidende Rolle. Verkehrskegel aus Materialien wie Polyvinylchlorid (PVC) widerstehen rauem Wetter und wiederholten Stößen. Auch nach Überfahren behalten sie ihre Form, um sicherzustellen, dass sie den Verkehr weiterhin effektiv leiten. Die Verwendung von recyceltem Kunststoff und nachhaltigen Materialien erhöht ihre Haltbarkeit zusätzlich und minimiert gleichzeitig die Umweltbelastung. Diese Kombination aus Sichtbarkeit und Haltbarkeit macht Leitkegel zu einem unverzichtbaren Hilfsmittel für die Verkehrssicherheit.

Auswirkungen auf die Reduzierung von Verkehrsunfällen

Die Weiterentwicklung der Verkehrsleitkegel hat wesentlich zur Reduzierung von Verkehrsunfällen beigetragen. Sie fragen sich vielleicht, wie diese einfachen Geräte eine solche Wirkung erzielen. Ihre leuchtenden Farben und reflektierenden Materialien machen den Fahrer auf Veränderungen der Straßenverhältnisse aufmerksam, hilft, Kollisionen zu verhindern. Durch die eindeutige Kennzeichnung von Baustellen oder Spurwechseln, Leitkegel leiten Autofahrer sicher durch potenziell gefährliche Bereiche.

Darüber hinaus, Die Flexibilität moderner Leitkegel minimiert Schäden an Fahrzeugen beim Aufprall. Wenn ein Auto gegen einen Kegel prallt, es biegt sich und kehrt in seine ursprüngliche Form zurück, Reduzierung des Unfallrisikos. Diese Funktion schützt nicht nur Fahrzeuge, sondern stellt auch sicher, dass die Kegel nach einem Aufprall funktionsfähig bleiben. Die strategische Platzierung von Leitkegeln in Hochrisikobereichen erhöht die Fußgängersicherheit weiter, indem sie den Fußgängerverkehr von Gefahrenzonen wegleitet.

Umweltüberlegungen

Nachhaltigkeit von Kunststoffkegeln

Sie fragen sich vielleicht, welche Auswirkungen Verkehrsleitkegel auf die Umwelt haben. Diese Verkehrsleitkegel, hauptsächlich aus PVC hergestellt, spielen eine wichtige Rolle für die Verkehrssicherheit. Jedoch, Ihre Herstellung und Entsorgung werfen Umweltbedenken auf. Der Lebenszyklus von Leitkegeln beginnt mit der Rohstoffgewinnung, das viel Energie benötigt und giftige Dämpfe abgibt. Dieser Prozess trägt zur Umweltverschmutzung und Verschwendung bei, die Umwelt negativ beeinflussen.

Um diese Probleme anzugehen, Die Branche sucht nach nachhaltigen Alternativen. Der Einsatz erneuerbarer Materialien kann den ökologischen Fußabdruck von Verkehrskegeln verringern. Zum Beispiel, Biologisch abbaubare Kunststoffe bieten eine vielversprechende Lösung. Sie zerfallen auf natürliche Weise, Minimierung von Abfall und Umweltverschmutzung. Durch die Einführung grüner Alternativen, Hersteller können Verkehrskegel herstellen, die sowohl effektiv als auch umweltfreundlich sind.

Für nachhaltige Leitkegellösungen, OPTsigns bietet umweltbewusste Optionen, einschließlich Kegeln aus recycelbaren Materialien.

Recycling und Umweltauswirkungen

Recycling spielt eine entscheidende Rolle bei der Bewältigung des Lebenszyklus von Verkehrskegeln. Sie werden überrascht sein, dass die meisten Verkehrskegel nicht recycelbar sind. Diese Einschränkung führt zu einer erheblichen Abfallansammlung. Bei unsachgemäßer Entsorgung, Diese Zapfen tragen zur Mikroplastik in der Umwelt bei, eine Gefahr für Ökosysteme darstellen.

Bemühungen zur Verbesserung von Recyclingprozessen konzentrieren sich auf die Entwicklung von Materialien, die einfacher zu recyceln sind. Durch die Verbesserung der Recyclingfähigkeit von Verkehrskegeln, Wir können Abfall und Umweltverschmutzung reduzieren. Dieser Ansatz schont nicht nur Ressourcen, sondern unterstützt auch eine nachhaltige Umwelt. Durch die Betonung von Recycling und nachhaltigen Praktiken wird sichergestellt, dass Verkehrskegel weiterhin ihren Zweck erfüllen, ohne den Planeten zu schädigen.

Moderne Innovationen im Leitkegeldesign

Technologische Fortschritte

You might be amazed at how technology has transformed traffic safety cones into smart devices. Modern traffic cones now incorporate advanced materials and features that enhance their functionality. Zum Beispiel, many cones use LED -Beleuchtung Verbesserung der Sichtbarkeit bei schlechten Lichtverhältnissen zu verbessern. This feature ensures that drivers can see them from a distance, Reduzierung des Unfallrisikos.

Another exciting development is the use of intelligente Zapfen mit Sensoren ausgestattet. These sensors can detect changes in traffic flow and provide real-time data to traffic management systems. This information helps in making informed decisions about road safety and traffic control. Zusätzlich, some cones now have Solarbetriebene LED-Leuchten, which are not only energy-efficient but also environmentally friendly.

Modern cones also feature collapsible designs for easy storage and transportation. You can stack them efficiently, saving space and making them convenient to deploy quickly. Diese Innovationen machen Leitkegel vielseitiger und effektiver für die Verkehrssicherheit.

Zukünftige Trends in der Verkehrssicherheit

Nach vorne schauen, Es erwarten Sie noch weitere spannende Trends im Leitkegel-Design. Eine mögliche Entwicklung ist die Integration von Konnektivitätsfunktionen. Stellen Sie sich Verkehrskegel vor, die mit Fahrzeugen kommunizieren, um Echtzeitwarnungen über den Straßenzustand zu geben. Diese Technologie könnte die Verkehrssicherheit erheblich verbessern, indem sie Unfälle verhindert, bevor sie passieren.

Ein weiterer Trend ist die Verwendung von nachhaltige Materialien. Da die Umweltbedenken zunehmen, Hersteller suchen nach umweltfreundlichen Alternativen zu herkömmlichen Materialien. Möglicherweise sehen Sie Verkehrskegel aus biologisch abbaubarem Kunststoff oder anderen erneuerbaren Ressourcen. Diese Materialien verringern die Umweltauswirkungen von Verkehrsleitkegeln und behalten gleichzeitig deren Wirksamkeit bei.

Endlich, die Zukunft bringen kann Anpassbare Verkehrskegel. Diese Zapfen können sich an verschiedene Situationen anpassen, indem sie ihre Farben ändern oder Nachrichten anzeigen. Diese Anpassungsfähigkeit würde sie in dynamischen Verkehrsumgebungen noch wertvoller machen. Da die Technologie immer weiter voranschreitet, Verkehrskegel werden wahrscheinlich intelligenter und effizienter, spielen eine entscheidende Rolle für die Verkehrssicherheit.

Die Geschichte der Verkehrsleitkegel zeigt einen bemerkenswerten Weg vom Holz zum Kunststoff, Dies spiegelt bedeutende Fortschritte in der Materialwissenschaft und im Design wider. Diese Veränderungen haben tiefgreifende Auswirkungen auf das moderne Verkehrsmanagement und die Verkehrssicherheit, Dadurch werden Verkehrskegel langlebiger und sichtbarer. Die Umstellung auf die Verwendung von recyceltem Kunststoff und nachhaltigen Materialien hat zu weniger Abfall und Umweltverschmutzung geführt, Beitrag zu einer gesünderen Umwelt. Wenn Sie in die Zukunft blicken, erwarten weitere Innovationen im Leitkegeldesign, einschließlich biologisch abbaubarer Materialien und IoT-Technologie, was ihre Funktionalität und Umweltfreundlichkeit verbessert. Verkehrsleitkegel werden sich weiterentwickeln, Sie spielen eine entscheidende Rolle bei der Gewährleistung der Verkehrssicherheit und der Minimierung der Umweltbelastung.