Durch die Auswahl der besten reflektierenden Materialien für Verkehrszeichen ist die Sicherheit der Menschen und befolgt die Regeln. Reflektierende Zeichen helfen, Unfälle zu stoppen, Besonders nachts oder bei schlechtem Wetter. Studien besagen, dass das Herstellen von Fahrbahnmarkierungen retoreflektierender kann auf Straßen mit vielen Gassen bis zu bis hin zu den Abstürmen senken 18%. Leute, die machen, kaufen, oder Planverkehrsschilder sollten die technischen Details jedes Zeichens überprüfen, Regeln, und Auswirkungen auf die Umwelt, damit sie am besten funktionieren.

Optraffic bietet eine hohe Qualität Reflektierende Zeichen die Sicherheits- und Regulierungsstandards erfüllen, Gewährleistung maximaler Sichtbarkeit und Haltbarkeit bei allen Wetterbedingungen. Mit unserem Sortiment an retroreflektierenden Materialien, OPTRAFFIC hilft Ihnen, die Verkehrssicherheit zu erhöhen und sicherzustellen, dass Ihre Verkehrssicherheitsschilder klar und effektiv sind, Tag oder Nacht.

Key Takeaways

- Reflektierende Materialien helfen Menschen, Verkehrszeichen nachts und bei schlechtem Wetter zu erkennen. Dies hilft den Fahrern, schneller zu reagieren und kann die Zahl der Unfälle verringern.

- Mikroprismenfolie in Diamantqualität ist am hellsten und hält am längsten. Es eignet sich am besten für stark befahrene Straßen und wichtige Schilder.

- Die Auswahl des richtigen Materials hängt von der Straße ab, Wie viele Autos nutzen es?, Beleuchtung, und Budget. Dies hilft, die Sicherheit auszugleichen, kosten, und wie lange die Zeichen anhalten.

- Schilder müssen richtig angebracht und häufig überprüft werden. Durch Reinigen und Überprüfen der Helligkeit sorgen Sie dafür, dass die Schilder sicher und funktionstüchtig sind.

- Neue Technologien wie intelligente reflektierende Folien und Nanotechnologie machen Schilder heller, stärker, und besser für die Umwelt.

Reflektierende Schilder und Verkehrssicherheit

Bedeutung für Nacht und Wetter

Reflektierende Schilder sind für die Verkehrssicherheit bei Nacht und schlechtem Wetter sehr wichtig. Autofahrer haben Schwierigkeiten, normale Schilder zu erkennen, wenn es dunkel ist oder Nebel herrscht, Regen, oder Schnee. Reflektierende Materialien funktionieren, indem sie Licht von Autoscheinwerfern zurück zum Fahrer senden. Dadurch sind die Schilder auch aus der Ferne besser erkennbar. Studien zeigen, dass besser reflektierende Materialien dazu beitragen, dass Autofahrer Schilder schneller wahrnehmen. Sie können auch schneller reagieren. Zum Beispiel, Die Verkehrsministerium von Ohio habe eine Studie gemacht. Sie fanden heraus, dass sie durch das Hinzufügen reflektierender Teile zu Chevron-Schildern hergestellt wurden 286% heller bei 225 Meter. Dies hilft Autofahrern, Veränderungen auf der Straße früher zu erkennen, besonders wenn es dunkel oder stürmisch ist.

Ältere Autofahrer und Menschen mit Sehproblemen profitieren am meisten von reflektierenden Schildern. Wenn es schwer zu sehen ist, wie bei starkem Regen oder Nebel, es ist viel schwieriger, Gefahren zu erkennen. Die Erkennungsentfernung kann um mehr als die Hälfte sinken. Reflektierende Materialien helfen, dieses Problem zu beheben. Sie geben allen Fahrern eine bessere Chance, Warnungen zu sehen und zu verstehen. Reflektierende Technologie wird auch in Schwimmwesten eingesetzt. Es hilft Menschen, in Notfällen gesehen zu werden und sicher zu bleiben. Diese Fakten zeigen, warum reflektierende Schilder für sicheres Reisen bei Nacht und schlechtem Wetter so wichtig sind.

Rolle bei der Unfallverhütung

Reflektierende Schilder helfen den Menschen nicht nur beim Sehen. Sie tragen auch dazu bei, Unfälle zu verhindern. Wenn Autofahrer die Schilder klar erkennen können, Sie treffen sicherere Entscheidungen. Sie müssen nicht plötzlich anhalten oder wenden. Verwendung von hochleistungsfähiger reflektierender Folie, wie ASTM D4956 Typ XI, hat die Zahl tödlicher nächtlicher Unfälle auf den Straßen, auf denen es eingesetzt wird, gesenkt. In einem anderen Fall, LED-Stoppschilder an Landkreuzungen verringern die Zahl der Unfälle 52%. Diese Beispiele zeigen, dass eine bessere Sichtbarkeit der Schilder die Straßen sicherer macht.

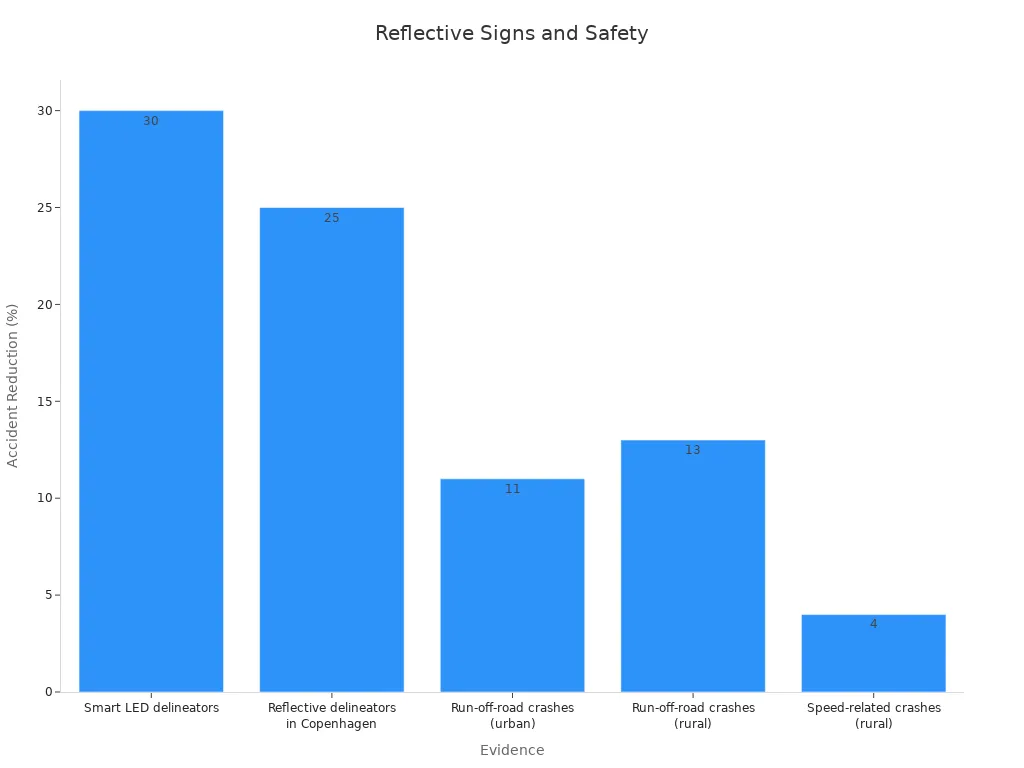

Statistische Daten belegen auch, dass reflektierende Schilder die Unfallrate senken:

| Beweisbeschreibung | Auswirkungen / Statistik |

|---|---|

| Intelligente LED-Leitpfosten | 30% Verringerung der Abstürze |

| Reflektierende Leitpfosten in Kopenhagen | 25% Rückgang der Unfälle |

| Randlinien auf Landstraßen | 26% Zu 33% Absturzreduzierung |

| Unfälle im Gelände (urban) | 11% Reduktion |

| Unfälle im Gelände (ländlich) | 13% Reduktion |

| Geschwindigkeitsbedingte Unfälle (ländlich) | 4% Reduktion |

Diese Zahlen zeigen, dass reflektierende Schilder sehr wichtig sind, um Unfälle zu verhindern und die Verkehrssicherheit zu gewährleisten.

Arten von reflektierenden Materialien

Ingenieurqualität

Reflektierende Folie in Ingenieurqualität ist der Grundtyp für Verkehrszeichen. Zur Herstellung verwenden die Hersteller Perlenkunststoff oder prismatische optische Technologie. Es entspricht normalerweise den ASTM D4956 Typ I-Regeln. Dieses Material eignet sich gut für Schilder, die nicht sehr wichtig sind, wie Park- oder Wegweiser. Die folgende Tabelle zeigt die Hauptmerkmale:

| Spezifikation / Merkmal | Beschreibung |

|---|---|

| Materialtyp | Reflektierende Folie aus perlenbesetztem Kunststoff |

| Retrorefektivität | Nachts hoch, entspricht Typ-I-Standards |

| Haltbarkeit | 5-7 Jahre im Freien |

| Anwendungsbereiche | Parken, kommerziell, und Informationszeichen |

| Umweltwiderstand | UV, Hitze, und feuchtigkeitsbeständig |

| Installation | Einfache Klebeanwendung auf Metall, Plastik, oder Glasfaser |

Reflektierende Folien in technischer Qualität sind nicht teuer und funktionieren gut an Orten mit wenig Verkehr. Es ist hell genug und einfach anzubringen, So viele Leute verwenden es für grafisches, reflektierendes Vinyl.

Hochintensität Prismatisch

Prismatische reflektierende Folie mit hoher Intensität verwendet eine spezielle prismatische und mikroprismatische Technologie. Dieses Material sendet Licht sehr gut zurück, Dadurch sind die Schilder nachts heller und besser zu erkennen. Es folgt den ASTM D4956-Typen 4 Und 5 Und MUTCD -Regeln. Hochintensive Prismenfolien werden durch UV-Strahlung nicht beschädigt, Wasser, oder schlechtes Wetter. Draußen hält es lange. Viele Städte nutzen dieses Material für wichtige Schilder an stark befahrenen Straßen.

Diamantqualität

Reflektierende Blechklage für Diamanten wird auch als verkehrsreflektierendes Vinyl in Diamantqualität bezeichnet. Es verwendet mikroprismatische Würfeleckenoptik. Dadurch wird es wieder nach oben gesendet 60% des Lichtes, Daher eignet es sich hervorragend für wichtige Verkehrskontrollschilder. Einige Hauptvorteile sind:

- Sehr hell – bis zu sechsmal heller als herkömmliche Markierungen.

- Hält lange an, mit 7 Jahren Garantie.

- Bleibt wetterfest, Schmutz, und Rost.

- Erfüllt oder übertrifft die NHTSA- und Einsatzfahrzeugvorschriften.

Reflektierende Folien in Diamantqualität helfen Menschen, Schilder sehr gut zu erkennen und halten lange, Auch an schwierigen Orten.

Fluoreszenzmaterialien

Fluoreszierende reflektierende Folie Dadurch sind Schilder bei schlechten Lichtverhältnissen und tagsüber besser zu erkennen. Hersteller testen diese Materialien, um sie zu erfüllen ISO 20471 Regeln. Studien zeigen, dass retroreflektierende Materialien vom Prismentyp bei Regen und von der Seite besser funktionieren. Normale Proben behalten auch nach Belastungstests ihr Retroreflexionsvermögen. Fluoreszierende Materialien eignen sich gut für Schulbereiche, Baubereiche, und Zebrastreifen, wo Menschen Zeichen klar erkennen müssen.

Mikroprismatisch vs. Glasperle

| Reflektierende Blechart | Retroreflexionsleistung | Typische Lichtrückkehr | Geeignete Anwendungen | Haltbarkeit/Lebensdauer |

|---|---|---|---|---|

| Ingenieurqualität (Glasperle) | Grundlegende Retroreflexion mit Glasperlen | Mäßig (ASTM D4956 Typ I) | Nichtkritische Zeichen | 5-7 Jahre |

| Hochintensität Prismatisch (HÜFTE) | Glasperlen im Wabengitter | ~16 % Lichtrückgabe | Verkehrszeichen, Bauzonen | Bis zu 10 Jahre |

| Diamant-Qualität, gewürfelt (Mikropromatisch) | Fortschrittliche mikroprismatische Würfeleckenoptik | Bis zu 60% Lichtrückkehr | Hohe Sichtbarkeitsanforderungen | Überlegene Haltbarkeit |

Mikroprismatische reflektierende Folie, wie Diamantqualität, ist heller und hält länger als Glasperlentypen. Es nutzt sich nicht durch Wetter oder Sonnenlicht ab. Damit ist es die beste Wahl für anspruchsvolle Arbeiten im Freien. Grafisch reflektierendes Vinyl mit mikroprismatischer Technologie sorgt für die Sicherheit der Menschen und spart Geld bei Reparaturen.

Bestes Material für Straßenschilder

Leistungsvergleich

Bei der Auswahl des besten Materials für Straßenschilder muss darauf geachtet werden, wie gut jedes einzelne Material funktioniert. Aluminium, HDPE, und PVC haben alle ihre eigenen Vorzüge. Aluminium ist leicht und rostet nicht. Es glänzt gut, wenn es eine gute Beschichtung hat. HDPE ist stark und lässt sich biegen, ohne zu brechen. Es hält Stößen und schlechtem Wetter stand. PVC ist steif und hält starkem Wind stand. Aber PVC kann reißen, wenn es sehr kalt wird.

Reflektierende Folientypen tragen dazu bei, dass Menschen Schilder besser erkennen können. Hochwertige Folie sorgt für grundlegenden Glanz. Diamantfolien glänzen am meisten. Das sagt eine 3M-Studie DG³-Folie in Diamantqualität reflektiert fast doppelt so viel Licht wie hochintensive Prismenfolien. Dadurch können Autofahrer nachts Schilder besser erkennen. Es hilft auch dabei, strenge Regeln für Straßenschilder einzuhalten.

Eine verkehrsreflektierende Querverweistabelle ermöglicht den einfachen Vergleich dieser Materialien. Die folgende Tabelle zeigt die wichtigsten Dinge, die es zu beachten gilt:

| Material / Blattart | Reflexionsvermögen | Haltbarkeit (Jahre) | Kosten pro ft² ($) | Wartung | Umweltauswirkungen |

|---|---|---|---|---|---|

| Aluminium + Diamantqualität | Höchste | 10-15 | 2.00 | Niedrig | Recycelbar |

| Aluminium + Hochintensität Prismatisch | Hoch | 7-10 | 0.75 | Niedrig | Recycelbar |

| HDPE + Ingenieurqualität | Mäßig | 5-7 | 0.60 | Niedrig | Recycelbar |

| PVC + Ingenieurqualität | Mäßig | 5-7 | 0.55 | Niedrig | Weniger umweltfreundlich |

Notiz: Diamond Grade-Folien eignen sich am besten zum Erkennen von Schildern und zum Befolgen von Regeln an wichtigen Stellen.

Kosten und Langlebigkeit

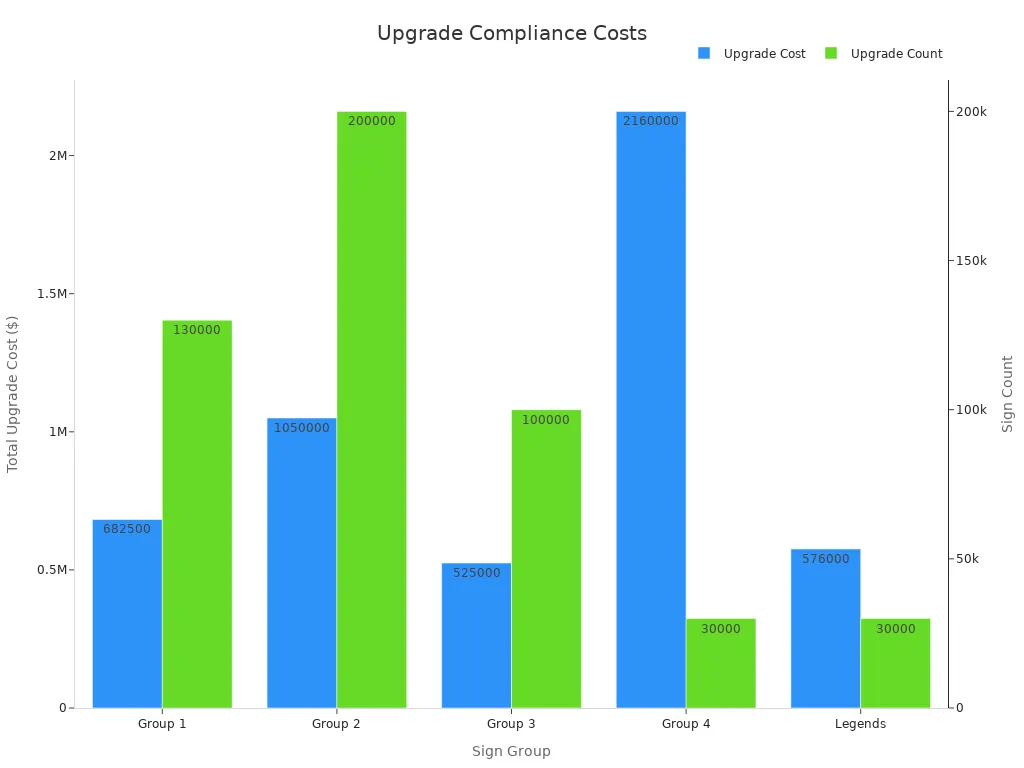

Sparen ist für Städte und Gemeinden sehr wichtig. Die Umrüstung von Straßenschildern auf besser reflektierende Materialien kostet zunächst viel. Die folgende Tabelle zeigt, wie viel es kostet, Schilder so aufzurüsten, dass sie den Mindestglanzvorschriften entsprechen:

Eine gute Querverweistabelle, die den Verkehr widerspiegelt, hilft Führungskräften dabei, das richtige Gleichgewicht zwischen Kosten und Haltbarkeit der Schilder zu finden. Aluminiumschilder mit Diamantfolie kosten zunächst mehr. Aber sie halten länger und brauchen weniger zu reparieren. Studien zeigen, dass blaue Schilder bis zu 12 Monate halten können 35 Jahre. Weiße oder rote Schilder müssen möglicherweise nachträglich geändert werden 10 Zu 16 Jahre. Viele Schilder glänzen auch nach der 10-Jahres-Garantie noch gut. Einige können bis zu halten 15 Jahre. Dies bedeutet, dass Städte ihre Schilder seltener austauschen müssen, Das spart Geld.

Neue Technologie, wie reflektierende Materialien auf Graphenbasis und neue Prismenfolien, Lässt Schilder noch länger halten und strahlender strahlen. Diese neuen Ideen helfen Städten, mit der Zeit mehr Wert aus jedem Schild zu ziehen.

Anwendungsszenarien

Das beste Material für Straßenschilder hängt davon ab, wo das Schild angebracht werden soll und wie viele Autos die Straße benutzen. Auf Autobahnen und großen Straßen, Am besten eignen sich Aluminiumschilder mit Diamantfolie. Sie helfen Autofahrern, Schilder schon von weitem zu erkennen, sogar nachts oder bei schlechtem Wetter.

Auf kleineren Straßen und in Stadtteilen, HDPE- oder PVC-Schilder mit Prismenfolie in technischer Qualität oder hochintensiver Qualität eignen sich gut. Diese Entscheidungen sparen Geld und lassen die Menschen die Zeichen dennoch klar erkennen. Sie eignen sich gut für Orte mit weniger Verkehr.

Besondere Orte, wie Schulkreuzungen und Baustellen, benötigen fluoreszierende und reflektierende Materialien in Diamantqualität. Dadurch sind Schilder tagsüber und nachts gut sichtbar. Dies gewährleistet die Sicherheit von Menschen und Arbeitern.

- Autobahnen: Aluminium + Diamantqualität

- Lokale Straßen: HDPE/PVC + Ingenieur oder hochintensives Prisma

- Schulzonen/Bau: Aluminium + Fluoreszierend oder Diamantqualität

Auswahl des besten Materials für Straßenschilder, Schauen Sie sich die verkehrsreflektierende Querverweistabelle an, Denken Sie an die Kosten, und passen Sie das Material an die Stelle an, an der das Schild angebracht werden soll. Dies hilft, alle zu schützen, folgt den Regeln, und spart auf lange Sicht Geld.

Faktoren für die Sichtbarkeit von Verkehrszeichen

Haltbarkeit

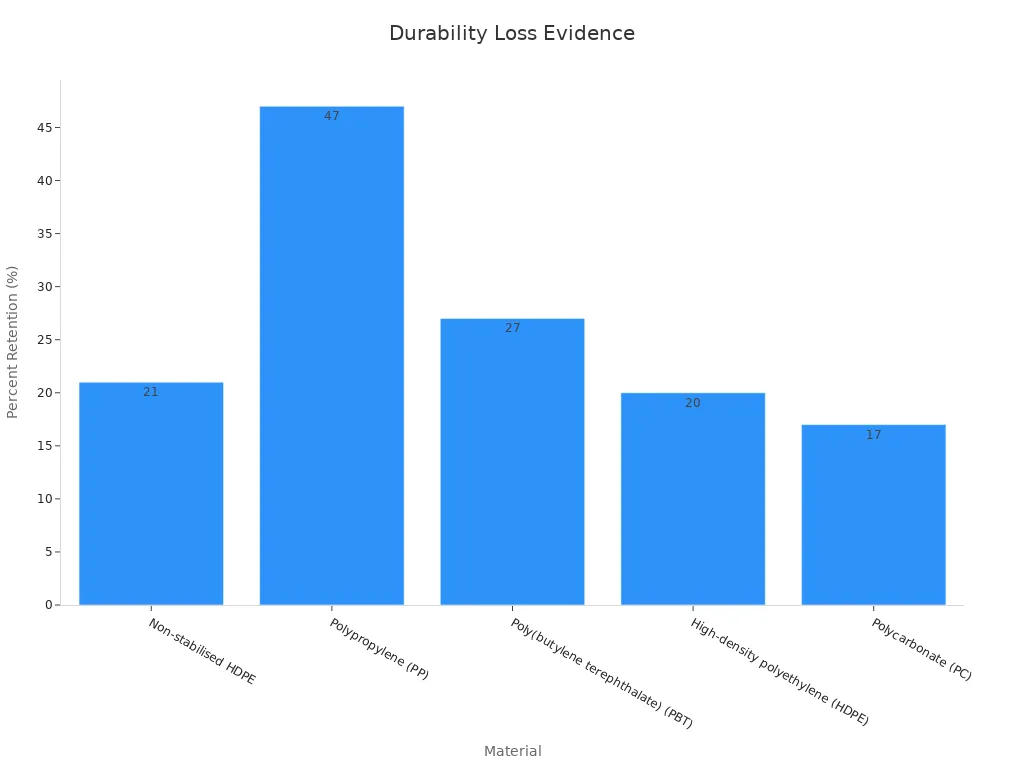

Wie lange ein Verkehrsschild hält, hängt vom Material ab. Sonne, Regen, und Verschmutzung kann die Schilder mit der Zeit schwächer machen. Manche Materialien verlieren schneller an Festigkeit als andere. Zum Beispiel, Nicht stabilisiertes HDPE wird danach viel schwächer 300 Stunden in der Sonne. Es hält nur 21% seiner Anfangsstärke. UV-stabilisiertes HDPE bleibt auch danach stark 1,300 Stunden in der Sonne. Auch Polycarbonat und Polypropylen werden nach Jahren im Freien schwächer. Die folgende Tabelle zeigt, wie sich verschiedene Materialien unter Witterungseinflüssen verändern:

| Material / Zustand | Belichtungstyp | Haltbarkeitsverlustmetrik | Wert / Ergebnis |

|---|---|---|---|

| Nicht stabilisiertes HDPE | Beschleunigtes UV (300 H) | Reduzierung der Zugfestigkeit und Dehnbarkeit | Reduziert auf 21% des Originals |

| UV-stabilisiertes HDPE | Beschleunigtes UV (1300 H) | Geringe Verschlechterung | Stabil bis 1300 h Belichtung |

| Polypropylen (Pp) | Natürliche Verwitterung | Beibehaltung der Bruchdehnung | 47% Zurückbehaltung |

| Polycarbonat (PC) | Natürliche Verwitterung | Beibehaltung der Bruchdehnung | 17% Zurückbehaltung |

PMMA-Proben bekommen mehr Risse und lassen nach Sonneneinstrahlung weniger Licht durch, Hitze, und Luftfeuchtigkeit. Eine Reinigung kann ein wenig helfen, aber nicht alles reparieren. Deshalb ist die Wahl des richtigen Materials wichtig, damit die Schilder lange klar bleiben.

Umweltauswirkungen

Die Umgebung beeinflusst, wie leicht ein Schild zu erkennen ist. Wo und in welcher Höhe ein Schild angebracht ist, kann sich mehr Schmutz ansammeln. Auch Luftverschmutzung macht Schilder schmutzig. Schmutzige Schilder sind schwerer zu erkennen und können unsicher sein. Agenturen nutzen diese Informationen, um die Reinigung zu planen und die Schilder gut lesbar zu halten.

- Kunststoffschilder sind günstiger, gehen aber bei schlechtem Wetter schneller kaputt.

- Aluminiumschilder rosten nicht und halten länger, Auch an schwierigen Orten.

- Keramikschilder sind sehr stabil und witterungsbeständig, aber sie kosten mehr.

- Glasschilder sind sehr hell, können aber leichter zerbrechen.

Tipp: Wählen Sie das richtige Material für Ihr Wetter und den Verkehr, damit Schilder länger halten und besser funktionieren.

Compliance -Standards

Um sicher zu sein, müssen Verkehrszeichen strengen Regeln folgen. In den Vereinigten Staaten, ANSI / ISES 107-2020 legt die Regeln für gut sichtbare Sicherheitsausrüstung fest. Diese Regeln decken wie hell ab, stark, und gut verarbeitet ist das Material. Tests prüfen, ob das Material nach dem Waschen und Gebrauch gut bleibt. Etiketten zeigen an, ob ein Produkt den Regeln entspricht und welcher Klasse es angehört.

In Europa, IN ISO 20471 sorgt dafür, dass Sicherheitskleidung und -materialien hell und robust bleiben. Es prüft die Farbe, Stärke, und tragen. Zertifizierte Produkte verfügen über ein CE-Zeichen und müssen alle fünf Jahre Tests bestehen. Diese Regeln tragen dazu bei, dass Schilder und Sicherheitsausrüstung unter allen Bedingungen gut funktionieren.

Notiz: Überprüfen, sauber, und tauschen Sie die Schilder häufig aus, damit sie sicher und gut sichtbar bleiben.

Fortschrittliche Technologien

Intelligente reflektierende Materialien

Intelligente reflektierende Materialien machen Verkehrsschilder besser. Diese Materialien nutzen neue Technologien, um den Menschen das Erkennen von Zeichen zu erleichtern. Viele Unternehmen verwenden mittlerweile Prismenfolie anstelle von Glasperlen. Prismatische Folien machen Schilder heller und aus vielen Blickwinkeln besser erkennbar. Einige neue Filme, wie die von AT SAFETY, sind sehr hell und dauern lange. Sie funktionieren tagsüber und nachts gut. Auch bei schlechtem Wetter verschleißen sie nicht so schnell.

- Hochwertige retroreflektierende Materialien wie RA2 helfen Menschen, Schilder bei jedem Licht zu erkennen.

- Intelligente Beleuchtungssysteme passen die Helligkeit der Schilder an die Umgebung an.

- Das spart Energie und hilft Menschen, Schilder besser zu erkennen.

- Automatisierte Tools prüfen, wie gut Schilder das Licht reflektieren.

- Fortgeschrittene Computerprogramme, wie YOLOv8, Helfen Sie beim Beobachten und Reparieren von Schildern.

Diese neuen Ideen helfen Autofahrern, Schilder klar zu erkennen, Auch wenn es dunkel oder regnet.

Nanotechnologie

Nanotechnologie macht Verkehrsschilder stärker und heller. Wissenschaftler fügen Farben und Beschichtungen winzige Dinge wie Nanoton oder Titandioxid hinzu. Diese Nanomaterialien tragen dazu bei, dass Schilder länger halten und sauber bleiben. Nanostrukturierte Beschichtungen haften gut auf Schildern, damit sie sich nicht ablösen. Untersuchungen zeigen, dass Nanoton Zeichen setzen kann 30% härter. Titandioxid hilft Schildern dabei, sich selbst zu reinigen, So bleiben sie mit weniger Arbeit hell.

Die Nanotechnologie trägt außerdem dazu bei, dass grafisch reflektierendes Vinyl seine Farbe und seinen Glanz behält. Schilder mit Nanokompositfarben können bis zu fünf Jahre halten. Alte Anstriche halten nur etwa drei Jahre. Dies bedeutet, dass Städte ihre Schilder seltener reparieren oder ersetzen müssen.

Umweltfreundliche Optionen

Bei Verkehrsschildern sind umweltfreundliche Entscheidungen wichtig. Neue reflektierende Materialien halten länger und verblassen nicht so schnell. Das bedeutet weniger Abfall. Viele Schilder verwenden mittlerweile mikroprismatische Folie oder Glasperlen. Diese reflektieren mehr Licht und benötigen keinen zusätzlichen Strom. Das spart Energie und verringert die Lichtverschmutzung.

- Reflektierende Schilder benötigen keine zusätzliche Beleuchtung, Das hilft dem Planeten.

- Diamantfolien halten länger und müssen nicht oft ausgetauscht werden.

- Regierungsvorschriften wie MUTCD besagen, dass Schilder sicher und gut für die Umwelt sein müssen.

- Immer mehr Menschen wünschen sich umweltfreundliche Materialien und intelligente Verkehrssysteme.

Verkehrsreflektierendes Vinyl und andere neue Materialien tragen dazu bei, dass Städte die Sicherheit der Menschen gewährleisten und die Natur schützen.

Auswahlfaktoren

Standort und Verkehrsaufkommen

Wichtig ist, wo ein Schild angebracht ist und wie viele Autos vorbeifahren. Auf stark befahrenen Straßen verschleißen reflektierende Schilder schneller. Autobahnen und Hauptkreuzungen benötigen starke Materialien, die lange hell bleiben. Wenn mehr Autos eine Straße benutzen, der Glanz der Markierungen verblasst schneller. Dadurch kann es zu weiteren Unfällen kommen, besonders nachts auf dunklen Straßen. Für diese Orte, Agenturen wählen reflektierende Typen, die länger halten und gut sichtbar bleiben. Für Parkplätze oder ruhige Nachbarschaftsstraßen sind nicht die stärksten Materialien erforderlich. Sie können Schilder mit mittlerem Glanz und mittlerer Stärke verwenden.

| Reflektierende Foliensorte | ASTM D4956 Typ | Reflexionsvermögen | Typische Anwendungen |

|---|---|---|---|

| Fortgeschrittener Ingenieurgrad (AEG) | Typ I | Niedrig | Parkplätze, Nachbarschaften, Lagerhäuser, Docks laden |

| Hochintensität Prismatisch (HÜFTE) | Typ III, Iv | Mittelhoch | Straßen, Stoppschilder, Geschwindigkeitsbegrenzungszeichen, regulatorische Zeichen |

| Diamantqualität (DG oder DG3) | Typ IX | Hoch-Sehr hoch | Permanente DOT-Projekte, stark befahrene Straßen, Warnzeichen, Arbeitszonen |

Lichtverhältnisse

Wie viel Licht um ein Schild herum ist, beeinflusst die Sichtbarkeit des Schildes durch Autofahrer. An Orten mit wenig Straßenbeleuchtung oder viel Nebel, Regen, oder Schnee, Schilder müssen leicht zu erkennen sein. Materialien mit höherer Retroreflexion helfen Autofahrern, Schilder aus größerer Entfernung zu erkennen. Dies senkt die Wahrscheinlichkeit von Unfällen. Prismenfolien und Diamantfolien funktionieren an diesen schwierigen Stellen am besten. Spezialbeschichtungen, wie UV-beständige und wetterfeste Schichten, Halten Sie die Schilder auch bei schlechtem Wetter hell. Agenturen sollten die Lichtverhältnisse und das Wetter vor Ort prüfen, bevor sie Materialien für neue Schilder auswählen.

Tipp: Verwenden Sie bei Dunkelheit eine Folie mit hoher Intensität oder Diamantqualität, damit Menschen die Schilder besser erkennen und sicher bleiben können.

Budgetüberlegungen

Für Städte und Gruppen, die sich um Straßen kümmern, ist Geld immer wichtig. Besser reflektierende Materialien kosten zunächst mehr, aber sie halten länger und brauchen weniger zu reparieren. Dies spart im Laufe der Zeit Geld für neue Schilder und Reparaturen. Auf stark befahrenen Straßen oder bei rauem Wetter, Auf lange Sicht ist es sinnvoll, mehr für gute Materialien auszugeben. Für ruhige Straßen oder kurzfristige Schilder, günstigere Optionen, die dennoch den Sicherheitsvorschriften entsprechen, sind in Ordnung. Viele Unternehmen stellen mittlerweile umweltfreundliche und recycelbare Folien her. Diese helfen Gruppen, Geld zu sparen und den Planeten zu schützen.

- Menschen wählen reflektierende Materialien nach Klasse aus, wenn sie sich an Regeln halten, wie sie sich auf die Umwelt auswirken, spezielle Beschichtungen, und ob sie zur Schildbasis passen.

- Agenturen sollten zunächst darüber nachdenken, wie viel sie ausgeben, wie lange die Schilder halten, und wie viel Arbeit sie später brauchen werden.

Erfahren Sie mehr darüber, wie Sie für Ihre Verkehrsschilder das richtige Gleichgewicht zwischen Kosten und Qualität finden, Lesen Sie unseren Blog: Kosten vs. Qualität in reflektierender Bleche: Was ist die Investition in die Straßenbeschilderung wert??

Installation und Wartung

Richtige Installation

Die richtige Anbringung reflektierender Verkehrsschilder gewährleistet die Sicherheit der Menschen. Es trägt auch dazu bei, dass Schilder länger halten. Die Arbeiter verwenden starke Pfosten, die nicht rosten, wie verzinkter Stahl oder U-Profil-Träger. Sie stecken diese Pfosten tief in den Beton, damit sie an Ort und Stelle bleiben. Jedes Schild zeigt direkt auf die Autos, die die Straße entlangfahren. Dadurch leuchtet das Schild hell und gut erkennbar. Nach dem Aufstellen des Schildes, Arbeiter kontrollieren es tagsüber und nachts. Sie verwenden spezielle Werkzeuge, sogenannte Retroreflektometer, um sicherzustellen, dass das Schild hell genug ist.

Tipp: Besatzungen sollten Sicherheitsregeln lernen. Sie müssen helle Kleidung tragen und die richtigen Werkzeuge verwenden. Dies trägt dazu bei, Unfälle zu verhindern und befolgt die OSHA-Vorschriften.

Städte wenden Regeln wie das Minnesota Manual on Uniform Traffic Control Devices an. Sie wählen ASTM-Folien basierend auf dem Zweck des Schilds aus. Typ XI-Folien sind für wichtige Schilder vorgesehen, Wie Stoppschilder. Typ IV steht für andere Zeichen. In Städten, Die Schilder müssen möglicherweise größer oder höher sein, da es mehr Dinge zu sehen gibt. Auf Landstraßen, Höhere Pfosten und besser reflektierende Materialien helfen den Fahrern, Schilder zu erkennen.

Wartungstipps

Durch die Überprüfung und Reinigung der Schilder bleibt die Funktionsfähigkeit oft erhalten. Agenturen schauen sich alle Schilder an 6 Zu 12 Monate. Arbeiter waschen Schmutz und Müll von der Schilderfläche. Sie prüfen, ob es verblasst, Schaden, oder ob jemand auf das Schild gezeichnet hat. Sie ziehen die Schrauben fest, damit sich das Schild nicht durch Wind oder Erschütterungen löst. Ein Schilderinventarsystem verfolgt, wann und wo jedes Schild angebracht wurde. Außerdem wird angezeigt, wann die Schilder zuletzt überprüft oder repariert wurden.

Notiz: Es ist wichtig, gut zur Umwelt zu sein. Viele Gruppen verwenden Schilder, die recycelt werden können. Sie recyceln auch alte Schilder, um weniger Müll zu produzieren.

Ersatzrichtlinien

Es gibt klare Schritte, wann Verkehrsschilder ersetzt werden müssen. Arbeiter prüfen, ob das Schild noch leuchtet und nicht kaputt ist. Die meisten Anzeichen dauern ungefähr 15 Jahre. Danach, Die Teams testen, wie hell das Schild ist, oder führen eine Studie durch, um festzustellen, ob es geändert werden muss. Schilder, die den Fahrern sagen, was sie tun sollen, oder sie warnen, werden zuerst ersetzt, Besonders auf belebten Straßen. Schilder, die nicht benötigt werden oder den Regeln nicht entsprechen, werden entfernt. Dies macht Straßen sicherer und weniger verwirrend. Über all diese Arbeiten wachen städtische Ingenieure. Sie achten darauf, dass es richtig gemacht wird und nicht zu viel kostet.

Durch häufiges Überprüfen und rechtzeitiges Ersetzen der Schilder bleiben die Straßen sicher und die Schilder für jedermann gut sichtbar.

Fallstudien

Erfolgreiche Projekte

Viele Orte haben die Straßen durch die Verwendung besser reflektierender Materialien sicherer gemacht. Schweden startete die “Vision Zero” Plan, Verkehrstote zu stoppen. Stockholm hat alte Schilder durch reflektierende Folien in Diamantqualität ersetzt. Dies führte dazu, dass die Schilder vorbei waren 50% nachts besser zu erkennen. Autofahrer sahen Warnschilder früher und konnten schneller reagieren. Es kam zu nächtlichen Unfällen an stark befahrenen Kreuzungen 20%.

Texas, in den Vereinigten Staaten, Bringen Sie hochintensive Prismenfolien auf Autobahnschildern an. Das texanische Verkehrsministerium überprüfte die Unfallzahlen vor und nach der Änderung. Sie fanden 15% weniger nächtliche Unfälle auf Landstraßen. Texas gab auch weniger Geld für die Reparatur von Schildern aus, weil die neuen länger hielten.

| Standort | Material verwendet | Hauptvorteil | Unfallreduzierung |

|---|---|---|---|

| Stockholm, Schweden | Diamond -Grade -Blatt | Verbesserte Sichtbarkeit bei Nacht | 20% |

| Texas, USA | Hochintensität Prismatisch | Längere Lebensdauer, Kosteneinsparungen | 15% |

Notiz: Durch die Verwendung besser reflektierender Materialien können Unfälle reduziert und im Laufe der Zeit Geld gespart werden.

Herausforderungen meistern

An manchen Orten herrscht schlechtes Wetter oder viel Umweltverschmutzung. Diese Dinge können Schilder beschädigen und sie schwer erkennbar machen. Tokio, Japan, Dies wurde durch die Verwendung von Mikroprismenfolie mit einer selbstreinigenden Schicht behoben. Dadurch blieben die Schilder auch nach starkem Regen und schmutziger Luft hell. Tokios Zeichen waren 30% während der Regenzeit leichter zu erkennen.

In Queensland, Australien, Salz und feuchte Luft ließen Schilder schnell verblassen. Stattdessen verwendete die Regierung UV-stabilisierte reflektierende Materialien. Diese Schilder verblassten nicht und rosteten nicht. Queensland musste weniger Schilder ersetzen und die Fahrer waren sicherer.

Anders als in den Vereinigten Staaten, wo reflektierende Materialien wie Diamond Grade häufig für Hauptstraßen verwendet werden, Australien hat seine eigenen Standards für reflektierende Verkehrszeichen, wie Klasse 1, Klasse 2, und Klasse 3 Materialien. Erfahren Sie mehr über diese Unterschiede und wie sie sich auf die Verkehrssicherheit auswirken, Lesen Sie unseren Blog: Überblick über reflektierende Verkehrszeichen Folienstandards in Australien.

Diese Geschichten zeigen, dass Städte echte Probleme lösen können, indem sie die richtigen reflektierenden Materialien für ihr Wetter und ihre Luft auswählen.

Die Auswahl des richtigen reflektierenden Materials sorgt für sichere Straßen und starke Schilder. Außerdem wird sichergestellt, dass die Schilder den Regeln entsprechen. Experten müssen Materialien auswählen, die zur Anzahl der Autos passen, wie hell die Gegend ist, und das Wetter. Schauen Sie sich Regeln wie MUTCD oder EN an 12899 Trägt dazu bei, dass die Qualität der Schilder erhalten bleibt. Vertrauenswürdige Lieferanten können hilfreiche Ratschläge geben.

Erfahren Sie mehr über Verkehrssicherheitsschilder, Schauen Sie sich unser an Vollständiger Leitfaden zu Kategorien und Standards für Verkehrssicherheitszeichen. Dieser Leitfaden bietet detaillierte Informationen zu den Arten von Schildern, Regulierungsstandards, und Best Practices, um sicherzustellen, dass Ihre Verkehrszeichen konform und effektiv sind.

FAQ

Was ist das haltbarste reflektierende Material für Verkehrsschilder??

Mikroprismenfolie in Diamantqualität hält am längsten. Es hält schlechtem Wetter stand, Sonnenlicht, und schmutzige Luft. Viele Gruppen nutzen es auf Autobahnen und wichtigen Straßen. Dieses Material bleibt mehr als zehn Jahre lang hell.

Wie oft sollten Behörden reflektierende Verkehrsschilder ersetzen??

Die meisten Gruppen überprüfen ihre Schilder einmal im Jahr. Sie wechseln die Vorzeichen, wenn sie nicht hell genug sind oder danach 10 Zu 15 Jahre. Auf stark befahrenen Straßen müssen die Schilder möglicherweise häufiger überprüft und ausgetauscht werden.

Funktionieren reflektierende Schilder bei jedem Wetter??

Reflektierende Materialien funktionieren gut bei Regen, Nebel, und Schnee. Mikroprismenfolien helfen Autofahrern, Schilder auch bei schlechtem Wetter zu erkennen. Reinigungsschilder sorgen oft dafür, dass sie hell und gut sichtbar sind.

Sind umweltfreundliche reflektierende Materialien erhältlich??

Ja, Viele Unternehmen verkaufen Aluminiumschilder, die recycelt werden können. Sie stellen auch prismatische Filme her, die lange halten. Diese Entscheidungen tragen dazu bei, Abfall zu reduzieren und die Umwelt zu schützen.

Wie können Behörden prüfen, ob ein Schild den Sichtbarkeitsstandards entspricht??

Agenturen testen mit Retroreflektometern, wie hell Schilder sind. Sie überprüfen die Ergebnisse mit MUTCD oder EN 12899 Regeln. Das Testen von Schildern trägt oft dazu bei, die Straßensicherheit zu gewährleisten und sicherzustellen, dass die Schilder den Regeln entsprechen.