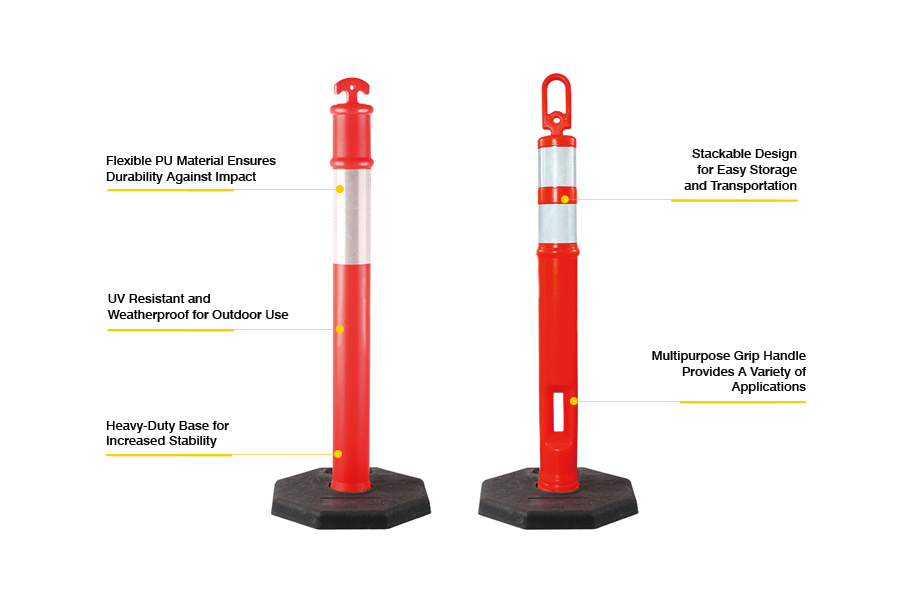

OPTsigns Channelizer Cone Delineators are expertly designed to provide exceptional visibility and portability in various traffic control applications. Constructed from flexible PU material, these delineator cones ensure durability against impact, making them ideal for use in busy environments. The channelizer cone with base features a heavy-duty base for increased stability, while its stackable design allows for easy storage and transportation. With multipurpose grip handles, these traffic delineator cones can be quickly and efficiently deployed wherever needed.

Whether directing traffic, delineating roadways, or marking temporary work zones, OPTsigns delineator cones are versatile tools that enhance safety. Their UV-resistant and weatherproof characteristics ensure reliable performance in outdoor conditions. Additionally, these delineator traffic cones can be used alongside barrier tapes, plastic chains, or hazard lights, making them suitable for construction sites, parking lots, and other traffic delineator post cones applications. Choose OPTsigns for a reliable solution that meets your traffic control needs while providing peace of mind.

*We respect your confidentiality and all information are protected.

| Height | 1075mm, 1080mm |

|---|---|

| Top Diameter | 97mm, 100mm |

| Base Diameter | 230mm |

| Weight | 6kgs |

| Material | PU |

| Colour | Orange Channelizer Cone with Black Base, Customizable |

| Reflective Tape | None, High-Intensity Grade, Class 1 |

| Customize | Logo or Marking |

A delineator cone is a flexible, upright marker used to guide and control traffic. Often brightly colored, these delineator cones improve visibility and can be used in various settings, including construction sites, roadwork, or event management, to effectively delineate boundaries and paths.

A channelizer cone with base is designed to provide clear visual guidance and enhance safety in traffic control. Its heavy-duty base ensures stability, making it suitable for directing vehicles and delineating roadways or work zones. This design helps prevent accidents by clearly marking boundaries and guiding drivers through temporary conditions.

The main difference lies in their usage: channelizer cones are typically used to direct traffic flow, while delineator cones are focused on marking boundaries. Channelizers often have a wider base for stability and are designed for more extensive traffic control applications, whereas delineators can be used for general guidance.

They are called delineators because they delineate, or mark, specific areas or paths to guide traffic safely. By providing visual cues, these delineator traffic cones help prevent confusion and enhance safety in various environments.

To place traffic delineator cones, start by assessing the area to determine where guidance is needed. Position the delineator traffic cones at regular intervals along the designated path, ensuring they are visible from a distance. Use additional cones to create barriers or direct traffic effectively, particularly in work zones or detours.