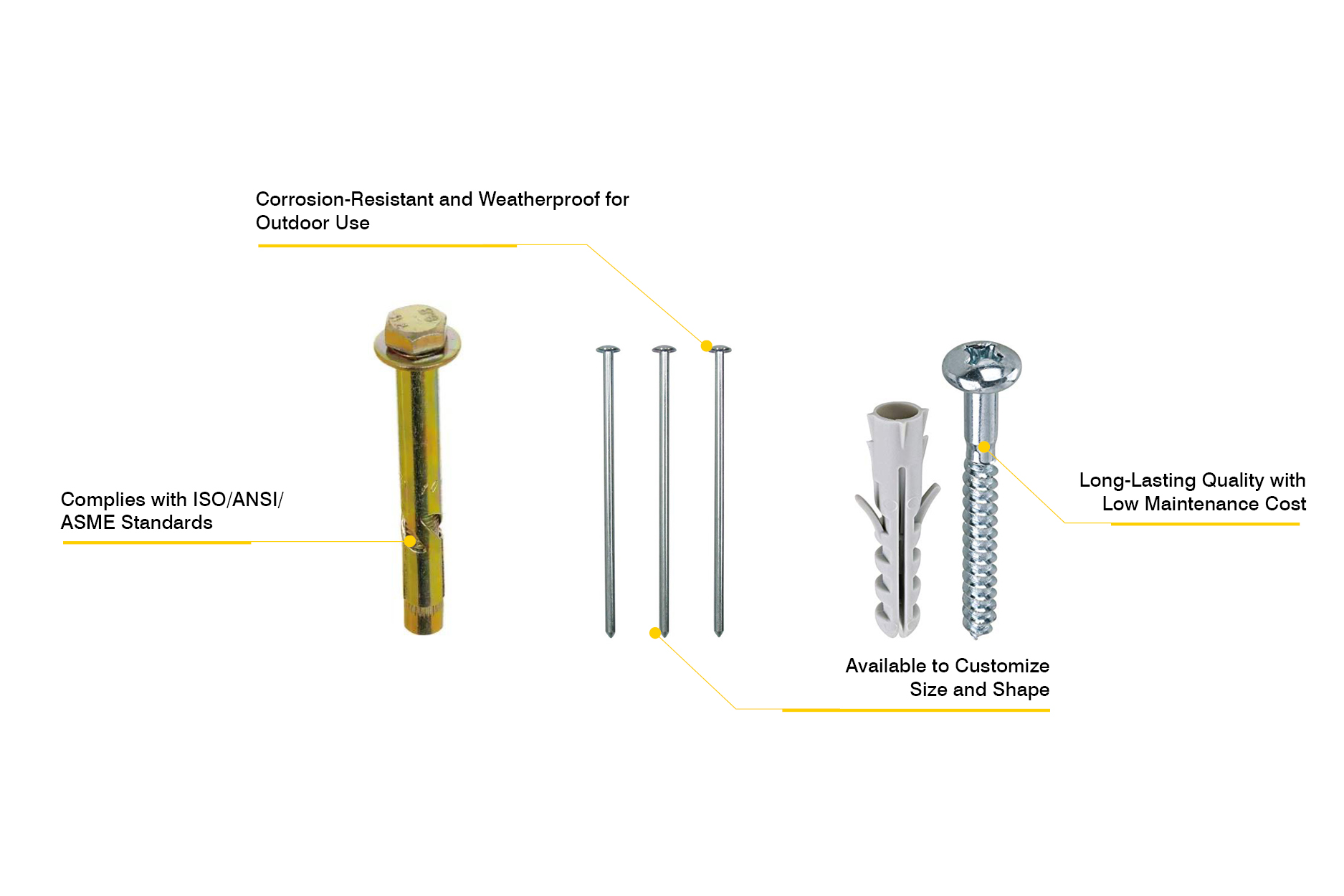

Manufactured with advanced electro-galvanized coating technology, OPTsigns dynabolts offer exceptional corrosion resistance and are weatherproof, making them ideal for outdoor use. These galvanized dynabolts are designed for long-lasting quality with low maintenance costs, ensuring reliable performance in various applications, such as installing brackets, traffic signs, and road delineators. For added versatility, our products comply with ISO, ANSI, and ASME standards, guaranteeing they meet rigorous safety and quality requirements. With a variety of dynabolt sizes available, customers can find the perfect fit for their specific needs.

Manufactured with advanced electro-galvanized coating technology, OPTsigns dynabolts offer exceptional corrosion resistance and are weatherproof, making them ideal for outdoor use. These galvanized dynabolts are designed for long-lasting quality with low maintenance costs, ensuring reliable performance in various applications, such as installing brackets, traffic signs, and road delineators. For added versatility, our products comply with ISO, ANSI, and ASME standards, guaranteeing they meet rigorous safety and quality requirements. With a variety of dynabolt sizes available, customers can find the perfect fit for their specific needs.

The dynabolt installation process is straightforward, supported by a comprehensive dynabolt installation guide to help users achieve optimal results. Whether you’re looking for stainless steel dynabolts for enhanced strength or specific configurations such as dynabolts for wheel stops, OPTsigns will meet your needs. Explore our range of dynabolts for sale today and experience the durability and reliability that sets OPTsigns apart in road safety solutions.

*We respect your confidentiality and all information are protected.

| Size | ��12*75mm, ��12*120mm, ��12*150mm, Customizable |

|---|---|

| Material | Galvanized Steel, Stainless Steel |

| Packing | Standard, Plastic Bag, Customizable |

| Customize | Size and Shape |

The bipod folding legs provide added support and stability to the sign frame, preventing tipping in windy conditions. Their design allows the frame to stand securely, making it ideal for managing traffic effectively.

The black sign frame not only offers a sleek aesthetic but also enhances visibility against various backgrounds. The dark color helps to highlight the safety messages displayed, making them more noticeable to motorists.

Yes, at OPTsigns, you can customize the multi-message sign frames with your own logos and markings. This feature allows you to tailor the messaging to meet specific traffic management needs while ensuring that your branding is visible

The multi frame sign legs serve to stabilize the entire structure, ensuring that the frame remains upright and secure during use. This feature is crucial for maintaining clear and visible safety messages in various traffic situations.

Installation is straightforward; simply set up the multi-message frame by extending the black bipod folding legs and attaching your sign.