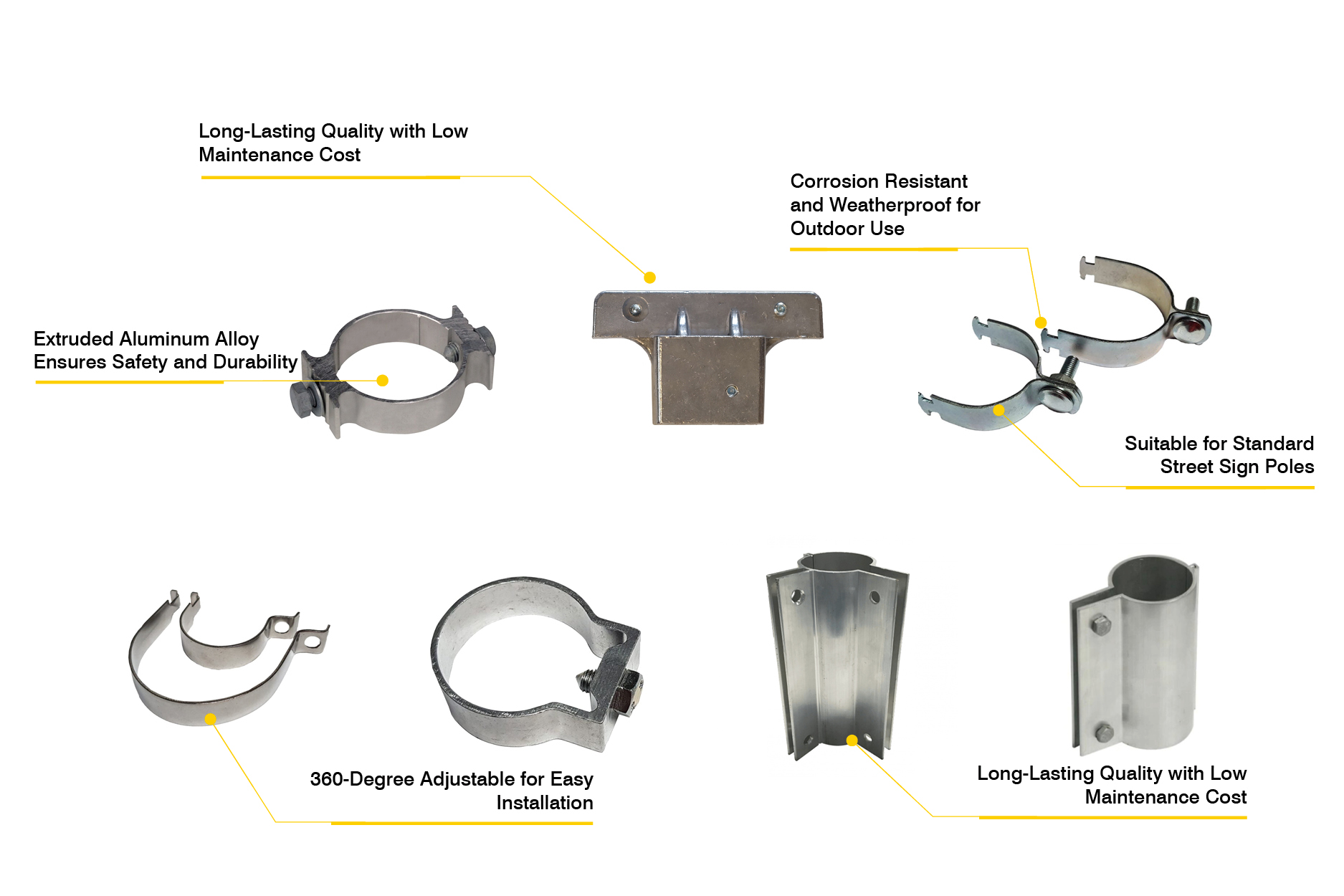

The OPTsigns 3-Way Street Name Brackets are crafted from premium aluminum alloy, offering a compact and robust structure that ensures both safety and long-lasting durability. These round brackets for post are specifically designed for outdoor use, featuring corrosion resistance and weatherproof properties to withstand harsh environments. Ideal for T-intersections, these street sign post brackets allow users to easily mount three street name signs on any standard street sign pole, providing a secure and highly visible display that requires minimal maintenance over time.

The OPTsigns 3-Way Street Name Brackets are crafted from premium aluminum alloy, offering a compact and robust structure that ensures both safety and long-lasting durability. These round brackets for post are specifically designed for outdoor use, featuring corrosion resistance and weatherproof properties to withstand harsh environments. Ideal for T-intersections, these street sign post brackets allow users to easily mount three street name signs on any standard street sign pole, providing a secure and highly visible display that requires minimal maintenance over time.

With a straightforward installation process, these aluminum post brackets make it simple to attach or remove signs as needed. The adaptability to various round posts means street name sign brackets fit most standard street sign poles seamlessly, delivering stable support for urban and rural street signs alike. For long-term reliability and low maintenance costs, these street sign post mounting brackets are an excellent choice for municipalities and contractors aiming for high-quality, resilient signage solutions.

*We respect your confidentiality and all information are protected.

| Height | 150mm, 200mm, Customizable |

|---|---|

| Hole Size | 25*12mm, Customizable |

| Material | Aluminum Alloy |

| Customize | Logo, Marking and Shape |

To use dynabolts, first select the appropriate size based on your project’s needs. Refer to the dynabolt installation guide for detailed instructions. Ensure the installation surface, like concrete, is clean and free of debris. Place the galvanized dynabolts through the fixture and into the pre-drilled hole, then tighten using a suitable tool.

Dynabolts function by expanding within a pre-drilled hole when tightened, creating a secure anchor. This expansion mechanism allows them to hold substantial loads. The stainless steel dynabolts are particularly effective in resisting corrosion, ensuring a long-lasting hold in various environments.

To install a dynabolt, first drill a hole into the concrete of the appropriate size. Insert the dynabolt into the hole, ensuring it is aligned with the fixture. Use a wrench to tighten the nut, which will cause the dynabolt to expand and grip the surrounding material securely. Follow the dynabolt installation guide for specific instructions based on the type used.

To remove dynabolts from concrete, first, unscrew the nut and washer. Then, use a hammer to gently tap the dynabolt, loosening it from the concrete. If it resists, you may need to drill further into the hole or use a wrench to rotate the galvanized dynbolt counterclockwise until it releases.

The weight a dynabolt can hold varies based on its size and the material it is anchored into. Generally, standard galvanized dynabolts can support significant loads when properly installed.