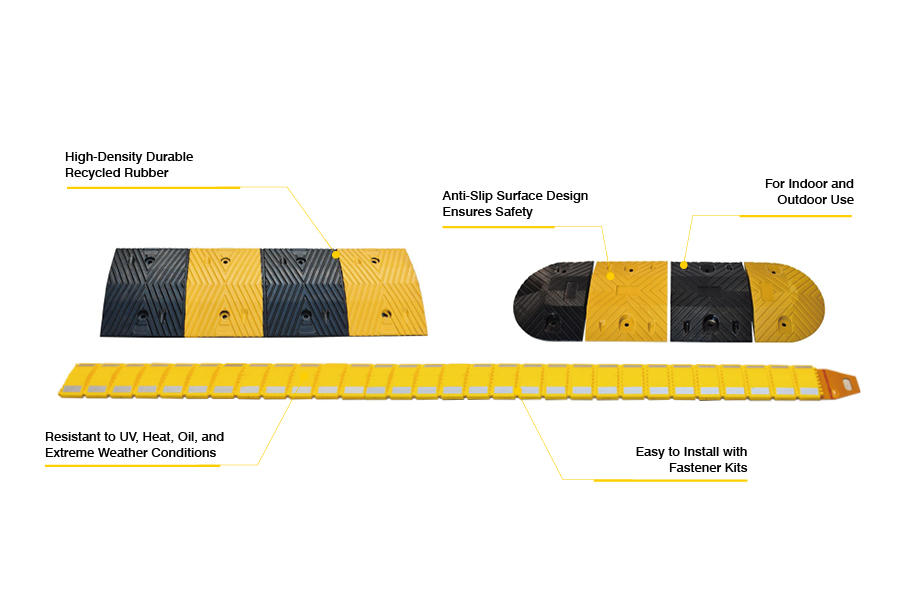

Optsigns Portable Speed Bump is engineered for seamless installation and effortless transportation, making it an ideal solution for managing traffic speed in various settings. Built with long-term durability, this speed bump withstands UV rays, heat, oil, and extreme weather conditions, ensuring reliable performance in any environment. Whether used in temporary work zones, parking lots, school zones, commercial areas, residential neighborhoods, or industrial facilities, the Portable Speed Bump effectively encourages drivers to reduce speed, enhancing safety for pedestrians and vehicles alike.

Optsigns Portable Speed Bump is engineered for seamless installation and effortless transportation, making it an ideal solution for managing traffic speed in various settings. Built with long-term durability, this speed bump withstands UV rays, heat, oil, and extreme weather conditions, ensuring reliable performance in any environment. Whether used in temporary work zones, parking lots, school zones, commercial areas, residential neighborhoods, or industrial facilities, the Portable Speed Bump effectively encourages drivers to reduce speed, enhancing safety for pedestrians and vehicles alike.

*We respect your confidentiality and all information are protected.

| Size | 3000*225*50mm |

|---|---|

| Weight | 13.7kgs |

| Reflective Sheet | None, High-Intensity Grade, Class 1 |

| Colour | Yellow, Customizable |

| Load Capacity | 15t |

| Customize | Custom Size and Weight |

Using the Optsigns temporary speed bump is straightforward and efficient. Begin by selecting a suitable location where you want to slow down traffic, such as a parking lot or school zone. Unpack the temporary speed bump and position it on the ground, ensuring it is aligned with the traffic flow. For added stability, secure it using the provided anchors or weights if needed. Once in place, the temporary speed bump will effectively alert drivers to reduce speed in the designated area, promoting safer driving practices.

Road Flares are used to enhance visibility and provide warnings in emergency situations, such as vehicle breakdowns, accidents, or hazardous road conditions. Road Flares help alert oncoming traffic and protect individuals in potentially dangerous areas.

Optsigns Road Flares feature high-intensity illumination, making Road Flares highly visible from a distance. Their bright light effectively signals for help and alerts drivers to potential hazards in various conditions.

Yes, roadside flares are designed to be weather-resistant, ensuring they perform reliably in rain, snow, and other adverse conditions. This durability makes them suitable for use in any environment where safety is a concern.

The burn time for Optsigns roadside flares typically ranges from 30 minutes to several hours, depending on the specific product. This duration provides ample time to alert oncoming traffic and ensure safety in emergency situations.

When used according to safety guidelines, traffic flares are safe to use. Traffic flares are designed for emergency situations and should be handled with care. Always keep flares away from flammable materials and ensure traffic flares are placed securely on stable surfaces.