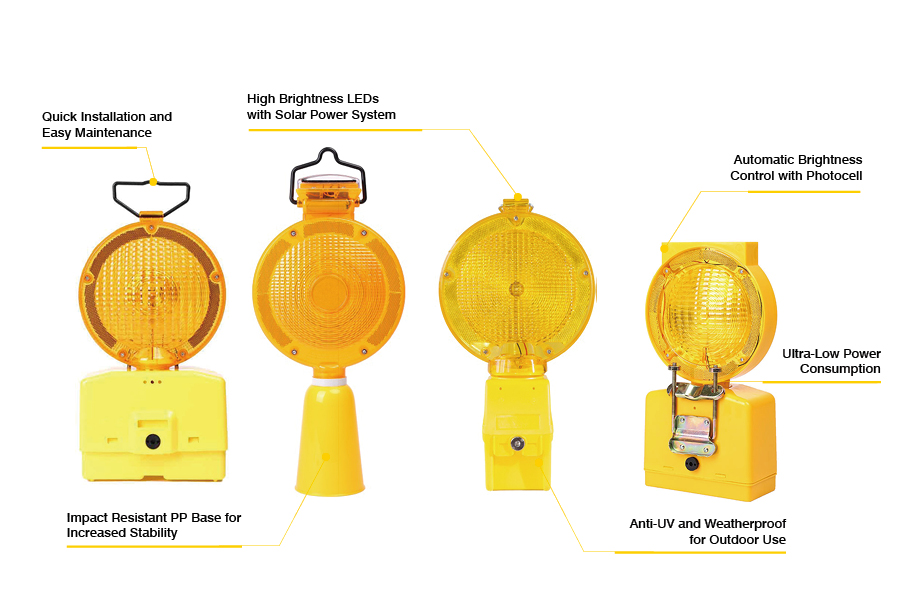

Optsigns barricade lights are a vital safety tool designed to enhance visibility and alertness in various environments. Featuring a single battery power source, these barricade lights offer a compact and energy-efficient solution without compromising on brightness. Equipped with advanced LED technology, barricade lights provide bright, attention-grabbing illumination that can easily be seen in low-light conditions and adverse weather. Ideal for use in construction sites, roadworks, and special events, these barricade lights ensure that barricades and traffic cones remain highly visible to both drivers and pedestrians. Their durable, weather-resistant design guarantees reliable performance, making them a trusted choice for improving safety in high-traffic areas.

*We respect your confidentiality and all information are protected.

| Size | 190*345*80mm |

|---|---|

| Double-Sided Amber Flash Light | |

| Material | PS Optical Lens Lamp Shade with PP Plastic Base |

| Flash Mode | 2 (60/min) |

| Small Base for Single Battery | |

| Option | 1*4R25 6V Battery |

Using Optsigns led barricade light (single battery type) is simple and effective for enhancing safety. First, securely place the warning light on top of a barricade, ensuring that the LED barricade light is positioned for maximum visibility. Turn on the light to activate its bright LED illumination, which will alert oncoming traffic and pedestrians about potential hazards. For optimal results, use these LED barricade lights in areas with limited visibility, such as construction zones or detours. Regularly check the battery to ensure the led barricade light is functioning properly and keep the light clean for maximum brightness.

To use dynabolts, first select the appropriate size based on your project’s needs. Refer to the dynabolt installation guide for detailed instructions. Ensure the installation surface, like concrete, is clean and free of debris. Place the galvanized dynabolts through the fixture and into the pre-drilled hole, then tighten using a suitable tool.

Dynabolts function by expanding within a pre-drilled hole when tightened, creating a secure anchor. This expansion mechanism allows them to hold substantial loads. The stainless steel dynabolts are particularly effective in resisting corrosion, ensuring a long-lasting hold in various environments.

To install a dynabolt, first drill a hole into the concrete of the appropriate size. Insert the dynabolt into the hole, ensuring it is aligned with the fixture. Use a wrench to tighten the nut, which will cause the dynabolt to expand and grip the surrounding material securely. Follow the dynabolt installation guide for specific instructions based on the type used.

To remove dynabolts from concrete, first, unscrew the nut and washer. Then, use a hammer to gently tap the dynabolt, loosening it from the concrete. If it resists, you may need to drill further into the hole or use a wrench to rotate the galvanized dynbolt counterclockwise until it releases.

The weight a dynabolt can hold varies based on its size and the material it is anchored into. Generally, standard galvanized dynabolts can support significant loads when properly installed.